Intro

Discover unique 3D printable butterfly knife designs, featuring intricate folding mechanisms, ergonomic handles, and customizable models for makers and collectors, showcasing innovative 3D printing techniques and DIY knife-making expertise.

The world of 3D printing has opened up a wide range of possibilities for creating complex and intricate designs, including functional items like knives. Among these, the butterfly knife, also known as a balisong, has garnered significant attention due to its unique design and the challenge of replicating its intricate mechanism using 3D printing technology. The butterfly knife, originating from the Philippines, is characterized by its folding design, where the blade is concealed within the handle when closed, and can be swiftly opened with a flipping motion of the wrist.

The interest in 3D printing a butterfly knife lies not only in its aesthetic appeal but also in the technical challenge it poses. The mechanism involves a series of interconnected parts that must work in harmony to allow the smooth opening and closing of the blade. This complexity makes the design an attractive project for enthusiasts of 3D printing and knife collectors alike. Moreover, the ability to customize the design, materials, and even the size of the knife offers a level of personalization that is difficult to achieve with mass-produced models.

One of the key benefits of 3D printing a butterfly knife is the potential for innovation in design. Traditional manufacturing methods can limit the complexity and customization of parts, whereas 3D printing allows for the creation of intricate geometries and customized features that would be impossible or too costly to produce through other means. This freedom in design enables creators to experiment with new mechanisms, materials, and aesthetic styles, potentially leading to the development of unique butterfly knife designs that stand out from their traditionally manufactured counterparts.

Design Considerations for 3D Printable Butterfly Knives

When designing a 3D printable butterfly knife, several factors must be considered to ensure the final product is functional, durable, and safe to use. The choice of material is crucial, as it affects the strength, weight, and overall performance of the knife. Common materials used for 3D printing, such as PLA and ABS, may not provide the necessary durability for a functional knife, leading many designers to explore the use of metal-filled filaments or to design the knife in such a way that it can be assembled with metal parts for the blade and critical mechanisms.

Another critical aspect is the design of the hinge and locking mechanisms. These must be precise and robust to ensure smooth operation and to prevent the knife from opening unintentionally. The complexity of these mechanisms can vary, from simple pivot points to more intricate systems involving springs and catches. Each design choice impacts the functionality, safety, and user experience of the butterfly knife.

Benefits of 3D Printing for Butterfly Knife Enthusiasts

For enthusiasts of butterfly knives, 3D printing offers a plethora of benefits. It allows for the creation of custom designs that cater to individual preferences, whether in terms of size, material, color, or mechanism complexity. This level of customization is unparalleled in the world of mass-produced knives, where designs are often constrained by manufacturing costs and the need for broad market appeal.

Furthermore, 3D printing enables the rapid prototyping and testing of new designs, facilitating innovation and improvement in butterfly knife mechanisms. Enthusiasts can design, print, and test their ideas quickly, iterating through different versions until they achieve the desired performance and aesthetic. This process not only fosters creativity but also contributes to the evolution of butterfly knife design as a whole.

Step-by-Step Guide to Designing a 3D Printable Butterfly Knife

Designing a 3D printable butterfly knife involves several steps, from conceptualization to the final design ready for printing. Here’s a simplified overview of the process:

- Conceptualization: Start by defining the key features of your butterfly knife, including its size, the type of mechanism, and the materials you plan to use.

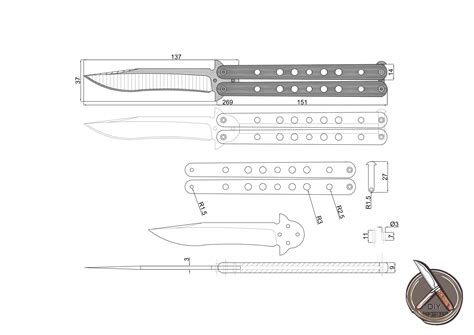

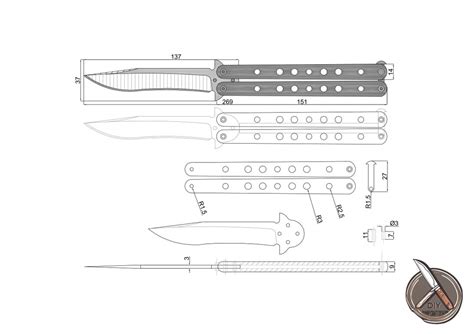

- Sketching: Create sketches of your design from different angles to visualize how the parts will interact and to identify potential issues.

- CAD Design: Use computer-aided design (CAD) software to create a digital model of your knife. This will allow you to precisely define the dimensions and interactions of the different parts.

- Mechanism Design: Focus on designing the hinge and locking mechanisms. These are critical for the functionality and safety of the knife.

- Material Selection: Decide on the materials for the different parts of the knife, considering factors like durability, weight, and aesthetics.

- Testing and Iteration: Once you have a design, create prototypes to test the functionality and make any necessary adjustments.

Challenges and Limitations of 3D Printing Butterfly Knives

While 3D printing offers many advantages for creating custom butterfly knives, there are also challenges and limitations to consider. One of the main issues is the strength and durability of the printed parts, especially when using common 3D printing materials like PLA or ABS. These materials may not provide the necessary resilience for a functional knife, particularly for the blade and critical mechanisms.

Another challenge is achieving the high level of precision required for the smooth operation of the knife’s mechanisms. Small discrepancies in the printing process can result in parts that do not fit together perfectly, leading to a knife that is difficult to open or close, or one that does not lock securely in place.

Future of 3D Printed Butterfly Knives

The future of 3D printed butterfly knives is promising, with advancements in 3D printing technology and materials science likely to address many of the current challenges. The development of stronger, more durable printing materials and improvements in printing resolution will enable the creation of more functional and reliable knives.

Moreover, as 3D printing becomes more accessible and affordable, we can expect to see a proliferation of custom and innovative butterfly knife designs. The community of enthusiasts and designers will continue to push the boundaries of what is possible, contributing to the evolution of the butterfly knife as both a functional tool and a work of art.

Gallery of 3D Printable Butterfly Knife Designs

Butterfly Knife Designs Image Gallery

What are the benefits of 3D printing a butterfly knife?

+The benefits include customization, rapid prototyping, and the ability to create complex designs that would be difficult or impossible to produce with traditional manufacturing methods.

What materials are best for 3D printing a butterfly knife?

+Materials with high strength and durability are preferred, such as metal-filled filaments. However, the choice of material depends on the intended use of the knife and the capabilities of the 3D printer.

How do I ensure the safety of my 3D printed butterfly knife?

+Ensure that the knife is designed with safety in mind, including a secure locking mechanism and handle design that prevents accidental opening. Additionally, always handle the knife with care and follow local laws and regulations regarding knife possession and use.

In conclusion, the world of 3D printable butterfly knives offers a fascinating intersection of technology, design, and functionality. As 3D printing technology continues to evolve, we can expect to see more innovative and reliable designs emerge. Whether you’re a seasoned enthusiast or just entering the world of butterfly knives, the possibilities offered by 3D printing are sure to captivate and inspire. We invite you to share your thoughts, experiences, and designs with our community, and to explore the endless possibilities that 3D printing has to offer for butterfly knife enthusiasts and beyond.