Intro

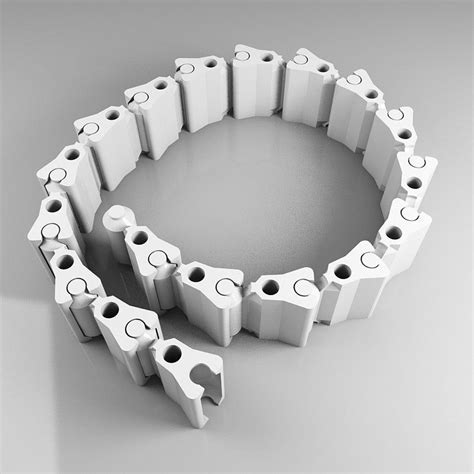

Discover innovative 3D printable chain designs, featuring intricate links, customizable models, and functional prototypes, perfect for makers, engineers, and hobbyists exploring additive manufacturing and 3D printing technology.

The world of 3D printing has opened up a vast array of possibilities for creating complex and intricate designs that were previously impossible to produce. One of the most fascinating applications of 3D printing is in the creation of chain designs. Chains have been a staple of engineering and design for centuries, used in everything from industrial machinery to jewelry and accessories. With the advent of 3D printing, designers and engineers can now create complex chain designs with unprecedented precision and customization.

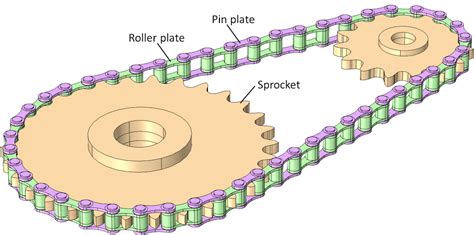

The importance of chain designs cannot be overstated. Chains are used in a wide range of applications, from power transmission and conveyor systems to medical devices and consumer products. The ability to create custom chain designs can significantly improve the performance, efficiency, and reliability of these systems. Additionally, 3D printed chain designs can be used to create complex geometries and patterns that would be difficult or impossible to produce using traditional manufacturing methods.

As the technology continues to evolve, we are seeing an increasing number of innovative and creative applications of 3D printed chain designs. From art and fashion to engineering and architecture, the possibilities are endless. In this article, we will explore the world of 3D printable chain designs, including the benefits, working mechanisms, and steps involved in creating these complex systems.

Introduction to 3D Printable Chain Designs

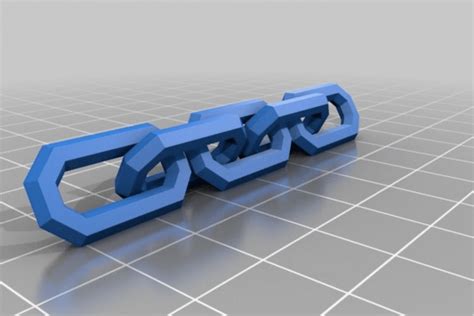

3D printable chain designs are created using computer-aided design (CAD) software and 3D printing technology. The design process typically involves creating a digital model of the chain, which is then sliced into individual layers and printed using a 3D printer. The resulting chain design can be customized to meet specific requirements, including material, size, and geometry.

One of the key benefits of 3D printed chain designs is the ability to create complex geometries and patterns. Traditional manufacturing methods often rely on simple, linear designs, which can limit the performance and efficiency of the chain. 3D printing, on the other hand, allows designers to create complex curves, angles, and shapes that can improve the overall performance of the chain.

Benefits of 3D Printable Chain Designs

There are several benefits to using 3D printed chain designs, including:

- Increased customization: 3D printing allows designers to create custom chain designs that meet specific requirements, including material, size, and geometry.

- Improved performance: Complex geometries and patterns can improve the overall performance and efficiency of the chain.

- Reduced weight: 3D printed chain designs can be optimized to reduce weight while maintaining strength and durability.

- Increased durability: 3D printed chain designs can be created with advanced materials and structures that improve durability and resistance to wear and tear.

Working Mechanisms of 3D Printable Chain Designs

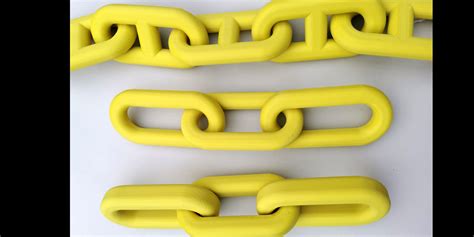

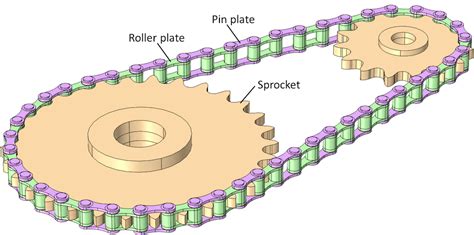

The working mechanisms of 3D printed chain designs are similar to those of traditional chains. The chain is composed of individual links that are connected to form a continuous loop. The links are designed to articulate and flex, allowing the chain to move smoothly and efficiently.

One of the key differences between 3D printed chain designs and traditional chains is the use of advanced materials and structures. 3D printing allows designers to create complex geometries and patterns that can improve the overall performance and efficiency of the chain. Additionally, 3D printed chain designs can be optimized to reduce weight while maintaining strength and durability.

Steps Involved in Creating 3D Printable Chain Designs

The steps involved in creating 3D printed chain designs include:

- Design: Create a digital model of the chain using CAD software.

- Slicing: Slice the digital model into individual layers.

- Printing: Print the individual layers using a 3D printer.

- Assembly: Assemble the individual links to form a continuous loop.

- Testing: Test the chain to ensure that it meets specific requirements, including performance, efficiency, and durability.

Applications of 3D Printable Chain Designs

3D printed chain designs have a wide range of applications, including:

- Industrial machinery: 3D printed chain designs can be used in industrial machinery, such as conveyor systems and power transmission systems.

- Medical devices: 3D printed chain designs can be used in medical devices, such as surgical instruments and implantable devices.

- Consumer products: 3D printed chain designs can be used in consumer products, such as jewelry and accessories.

- Art and fashion: 3D printed chain designs can be used in art and fashion, such as sculptures and clothing.

Future of 3D Printable Chain Designs

The future of 3D printed chain designs is exciting and rapidly evolving. As the technology continues to improve, we can expect to see even more innovative and creative applications of 3D printed chain designs. Some potential areas of development include:

- Advanced materials: The development of advanced materials and structures that can improve the performance and efficiency of 3D printed chain designs.

- Increased customization: The ability to create highly customized 3D printed chain designs that meet specific requirements.

- Improved durability: The development of 3D printed chain designs that are more durable and resistant to wear and tear.

3D Printable Chain Designs Image Gallery

What are the benefits of 3D printed chain designs?

+The benefits of 3D printed chain designs include increased customization, improved performance, reduced weight, and increased durability.

What are the steps involved in creating 3D printed chain designs?

+The steps involved in creating 3D printed chain designs include design, slicing, printing, assembly, and testing.

What are the applications of 3D printed chain designs?

+The applications of 3D printed chain designs include industrial machinery, medical devices, consumer products, and art and fashion.

In conclusion, 3D printable chain designs are a rapidly evolving field that offers a wide range of benefits and applications. As the technology continues to improve, we can expect to see even more innovative and creative uses of 3D printed chain designs. Whether you are an engineer, designer, or simply someone interested in the latest advancements in technology, 3D printable chain designs are definitely worth exploring. We invite you to share your thoughts and experiences with 3D printed chain designs in the comments below, and to stay tuned for future updates and developments in this exciting field.