Intro

Discover vibrant 3D DM screen prints, featuring dimensional texture and depth. Explore techniques, designs, and applications of 3D printing and screen printing combined.

The world of 3D printing has revolutionized the way we create and produce objects, and one of the most exciting developments in this field is the use of 3D DM screen prints. This technology has opened up new possibilities for designers, artists, and manufacturers, allowing them to create complex and intricate designs with unprecedented precision and accuracy. In this article, we will delve into the world of 3D DM screen prints, exploring their benefits, working mechanisms, and applications.

The importance of 3D DM screen prints cannot be overstated. They have the potential to transform industries such as healthcare, aerospace, and automotive, where complex and customized parts are in high demand. Moreover, 3D DM screen prints have also enabled the creation of complex artworks and designs that were previously impossible to produce. As we continue to push the boundaries of what is possible with 3D printing, it is essential to understand the technology behind 3D DM screen prints and how they are changing the game.

The concept of 3D DM screen prints is based on the principle of layer-by-layer deposition of materials. This process involves the use of a digital model or design, which is then sliced into thin layers and printed using a 3D printer. The printer deposits the material, layer by layer, to create the final product. The use of a screen printing technique allows for the creation of complex and intricate designs, with high levels of precision and accuracy. This technology has enabled the production of objects with complex geometries, such as hollow structures, lattice patterns, and customized shapes.

Introduction to 3D DM Screen Prints

The benefits of 3D DM screen prints are numerous. They offer high levels of precision and accuracy, allowing for the creation of complex and customized designs. Moreover, this technology enables the production of objects with complex geometries, such as hollow structures and lattice patterns. The use of 3D DM screen prints also allows for the creation of objects with customized properties, such as texture, color, and material composition. This has opened up new possibilities for designers and manufacturers, enabling them to create objects that are tailored to specific applications and industries.

Working Mechanisms of 3D DM Screen Prints

The working mechanisms of 3D DM screen prints involve the use of a digital model or design, which is then sliced into thin layers and printed using a 3D printer. The printer deposits the material, layer by layer, to create the final product. The use of a screen printing technique allows for the creation of complex and intricate designs, with high levels of precision and accuracy. This technology has enabled the production of objects with complex geometries, such as hollow structures, lattice patterns, and customized shapes.

Steps Involved in 3D DM Screen Prints

The steps involved in 3D DM screen prints include: * Design: The first step involves creating a digital model or design using computer-aided design (CAD) software. * Slicing: The digital model is then sliced into thin layers, which are used to create the final product. * Printing: The layers are then printed using a 3D printer, which deposits the material, layer by layer, to create the final product. * Post-processing: The final product may require post-processing, such as sanding or painting, to achieve the desired finish.Applications of 3D DM Screen Prints

The applications of 3D DM screen prints are numerous and varied. They have been used in industries such as healthcare, aerospace, and automotive, where complex and customized parts are in high demand. Moreover, 3D DM screen prints have also enabled the creation of complex artworks and designs that were previously impossible to produce. Some of the most significant applications of 3D DM screen prints include:

- Healthcare: 3D DM screen prints have been used to create customized prosthetics, implants, and surgical models.

- Aerospace: 3D DM screen prints have been used to create lightweight and complex aircraft components, such as engine parts and satellite components.

- Automotive: 3D DM screen prints have been used to create customized car parts, such as dashboard components and engine parts.

Benefits of 3D DM Screen Prints in Healthcare

The benefits of 3D DM screen prints in healthcare are numerous. They have enabled the creation of customized prosthetics, implants, and surgical models, which have improved patient outcomes and reduced recovery times. Moreover, 3D DM screen prints have also enabled the creation of complex and customized medical devices, such as pacemakers and implantable defibrillators.Future of 3D DM Screen Prints

The future of 3D DM screen prints is exciting and promising. As the technology continues to evolve, we can expect to see new and innovative applications in industries such as healthcare, aerospace, and automotive. Moreover, 3D DM screen prints are also expected to play a significant role in the creation of complex and customized artworks and designs. Some of the most significant trends that are expected to shape the future of 3D DM screen prints include:

- Increased use of advanced materials: 3D DM screen prints are expected to use advanced materials, such as nanomaterials and biomaterials, to create objects with customized properties.

- Improved precision and accuracy: 3D DM screen prints are expected to achieve higher levels of precision and accuracy, enabling the creation of complex and intricate designs.

- Increased use of artificial intelligence: 3D DM screen prints are expected to use artificial intelligence to optimize the printing process and improve the quality of the final product.

Challenges and Limitations of 3D DM Screen Prints

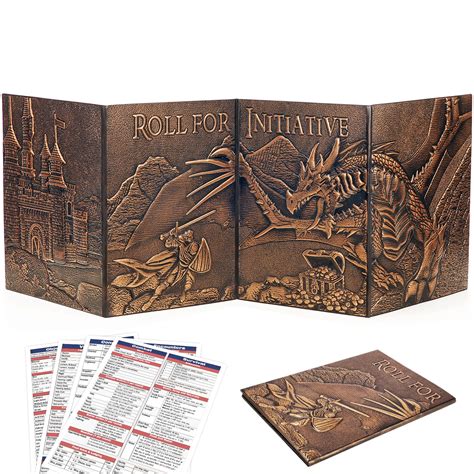

Despite the numerous benefits and applications of 3D DM screen prints, there are also several challenges and limitations that need to be addressed. Some of the most significant challenges and limitations include: * High cost: 3D DM screen prints are currently expensive, which limits their accessibility to many industries and applications. * Limited availability of materials: 3D DM screen prints are limited by the availability of materials, which can restrict their use in certain applications. * Limited precision and accuracy: 3D DM screen prints can be limited by their precision and accuracy, which can affect the quality of the final product.3D DM Screen Prints Image Gallery

What are 3D DM screen prints?

+3D DM screen prints are a type of 3D printing technology that uses a screen printing technique to create complex and intricate designs.

What are the benefits of 3D DM screen prints?

+The benefits of 3D DM screen prints include high levels of precision and accuracy, customized properties, and the ability to create complex geometries.

What are the applications of 3D DM screen prints?

+The applications of 3D DM screen prints include healthcare, aerospace, automotive, and the creation of complex artworks and designs.

In conclusion, 3D DM screen prints are a revolutionary technology that has opened up new possibilities for designers, artists, and manufacturers. With their high levels of precision and accuracy, customized properties, and ability to create complex geometries, 3D DM screen prints are expected to play a significant role in shaping the future of various industries. We invite you to share your thoughts and experiences with 3D DM screen prints in the comments below. Whether you are a seasoned expert or just starting to explore the world of 3D printing, we encourage you to join the conversation and share your insights. Together, we can unlock the full potential of 3D DM screen prints and create a brighter future for all.