Intro

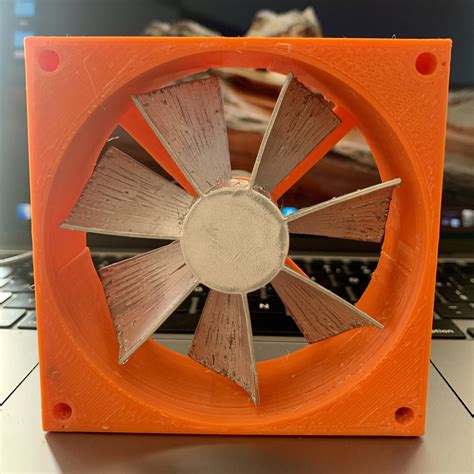

Discover 3D printable fan designs, models, and templates for DIY enthusiasts, featuring customizable blades, motors, and mounts, perfect for makers and hobbyists seeking innovative cooling solutions and creative projects.

The world of 3D printing has revolutionized the way we create and design objects, allowing us to bring complex ideas to life with precision and accuracy. One of the most exciting applications of 3D printing is in the creation of functional items, such as fans, that can be customized to meet specific needs and preferences. In this article, we will delve into the world of 3D printable fans, exploring their benefits, working mechanisms, and the steps involved in creating your own custom fan.

The importance of 3D printable fans cannot be overstated, as they offer a unique combination of functionality, customization, and affordability. With the ability to design and print your own fan, you can create a device that meets your specific needs, whether it's for cooling, ventilation, or simply as a decorative piece. Moreover, 3D printable fans have the potential to disrupt traditional manufacturing methods, allowing individuals to create their own products without relying on mass production.

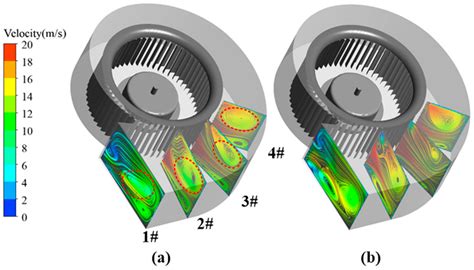

As we explore the world of 3D printable fans, it's essential to understand the benefits they offer. For instance, 3D printed fans can be designed with complex geometries and structures that cannot be produced using traditional manufacturing methods. This allows for improved airflow, increased efficiency, and reduced noise levels. Additionally, 3D printable fans can be made from a variety of materials, including plastics, metals, and ceramics, offering a range of options for different applications.

Introduction to 3D Printable Fans

Benefits of 3D Printable Fans

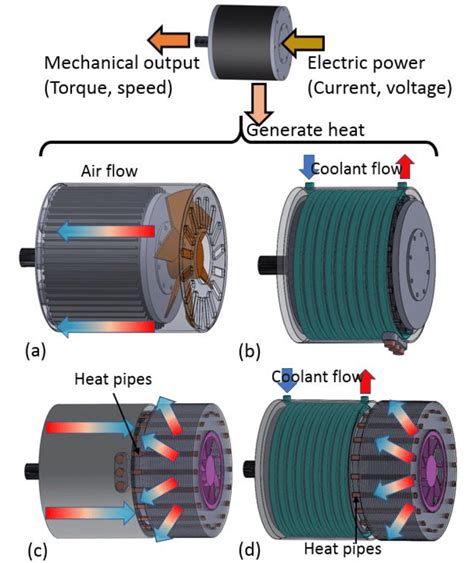

Working Mechanisms of 3D Printable Fans

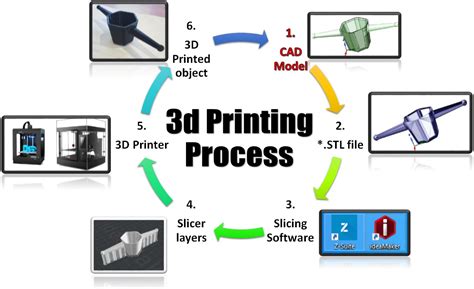

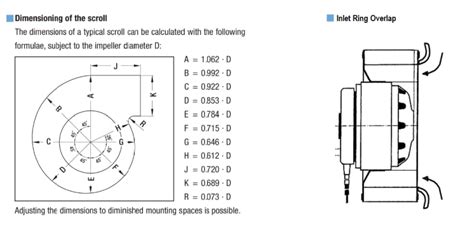

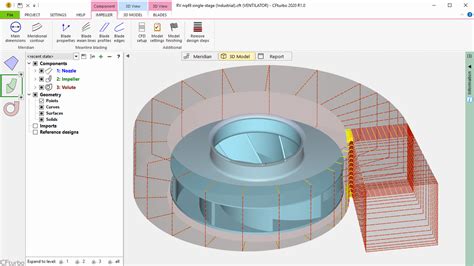

Steps Involved in Creating a 3D Printable Fan

Practical Examples of 3D Printable Fans

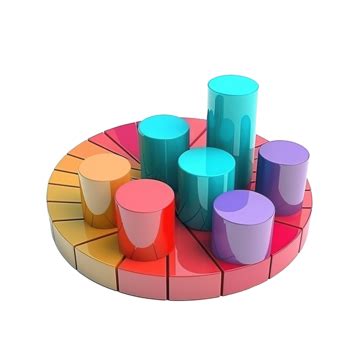

Statistical Data on 3D Printable Fans

Gallery of 3D Printable Fans

3D Printable Fan Image Gallery

Frequently Asked Questions

What is a 3D printable fan?

+A 3D printable fan is a fan that is created using 3D printing technology, allowing for customization and improved efficiency.

What are the benefits of 3D printable fans?

+The benefits of 3D printable fans include customization, affordability, efficiency, and sustainability.

How do I create a 3D printable fan?

+To create a 3D printable fan, you need to design the digital model using CAD software, select the materials, print the fan, assemble the components, and test the fan.

What are the applications of 3D printable fans?

+The applications of 3D printable fans include desktop fans, ceiling fans, industrial fans, and custom fan designs.

What is the future of 3D printable fans?

+The future of 3D printable fans is expected to be significant, with growing demand for customized and efficient products driving the market.

In conclusion, 3D printable fans offer a unique combination of functionality, customization, and affordability, making them an exciting development in the world of 3D printing. As the technology continues to evolve, we can expect to see even more innovative applications of 3D printable fans in various industries. Whether you're a hobbyist, a designer, or an engineer, the possibilities of 3D printable fans are endless, and we invite you to explore this fascinating world and discover the potential of 3D printing for yourself. Share your thoughts and experiences with 3D printable fans in the comments below, and don't forget to share this article with your friends and colleagues who might be interested in this topic.