Intro

Discover 3D printing techniques to create custom flutes, exploring additive manufacturing, flute design, and 3D modeling for a unique musical instrument.

The world of music has undergone significant transformations with the advent of technology, and one of the most exciting developments is the ability to 3D print musical instruments. Among these, the flute is an instrument that has garnered considerable attention due to its complex structure and the precision required in its manufacture. 3D printing a flute is not only a fascinating project for music enthusiasts and makers but also a testament to the versatility and capabilities of 3D printing technology.

The idea of creating a musical instrument like the flute, which requires precise tuning and craftsmanship, through a digital manufacturing process, seems almost magical. However, with advancements in 3D printing, it's now possible to design and print flutes that are not only aesthetically pleasing but also produce high-quality sound. This innovation opens up new avenues for musicians, educators, and hobbyists alike, making musical instruments more accessible and customizable than ever before.

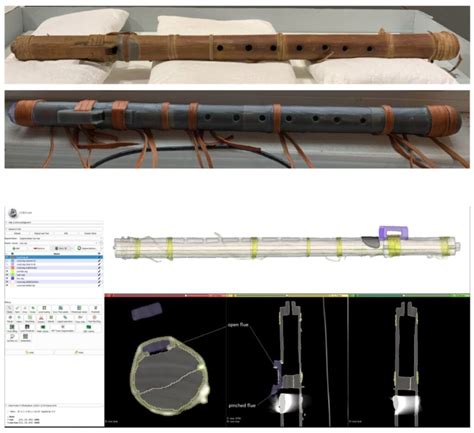

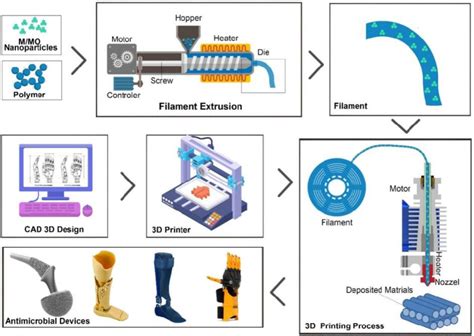

For those interested in 3D printing a flute, the journey begins with design. The flute's design is crucial, as it affects both the playability and the sound quality of the instrument. Software such as CAD (Computer-Aided Design) programs allows users to create or modify flute designs, taking into account the intricate details necessary for a functional flute, such as the finger holes, the embouchure hole, and the internal bore. The design phase is where creativity meets precision, as makers can experiment with different shapes, materials, and innovations that traditional manufacturing methods might not accommodate.

Benefits of 3D Printing a Flute

The benefits of 3D printing a flute are multifaceted. Firstly, it offers a cost-effective solution for those interested in owning a flute. Traditional flute-making is a labor-intensive process that requires skilled craftsmanship, making high-quality flutes quite expensive. In contrast, 3D printing reduces production costs significantly, making flutes more accessible to a wider audience. Additionally, 3D printing allows for rapid prototyping and production, which means that designers can quickly test and refine their designs, leading to innovations and improvements at a much faster pace than traditional methods.

Another significant advantage of 3D printing flutes is the customization aspect. With traditional manufacturing, creating a customized flute to fit an individual's preferences or needs can be challenging and expensive. 3D printing, however, enables the easy customization of flute designs, allowing for adjustments in size, material, and even the addition of unique features that can enhance playability or sound quality. This level of personalization can be particularly beneficial for musicians with specific requirements or preferences that aren't met by standard flutes.

The Process of 3D Printing a Flute

The process of 3D printing a flute involves several steps, from design to post-printing refinement. After designing the flute, the next step is to prepare the design for printing, which includes slicing the model into layers that the 3D printer can understand. The choice of material is also critical, as it affects the sound quality and durability of the flute. Common materials used for 3D printing flutes include plastics, metals, and wood-based filaments, each offering different acoustic properties and aesthetic appeals.

Once the printing is complete, the flute may require some post-processing to achieve the desired finish and playability. This can include sanding to smooth out rough edges, applying coatings to enhance the sound, or assembling parts if the flute was printed in sections. For those new to 3D printing, it's essential to have a basic understanding of the printing process and the materials involved to ensure a successful outcome.

Challenges and Considerations

While 3D printing a flute offers many benefits, there are also challenges and considerations to keep in mind. One of the primary concerns is the sound quality. The material and the printing process can significantly affect the flute's tone, intonation, and overall playability. Achieving a sound that is comparable to traditionally made flutes can be difficult and may require extensive experimentation with designs and materials.

Another challenge is the durability of the 3D printed flute. Depending on the material used, the flute might be more prone to damage or wear and tear, especially if it's made from a brittle or soft material. This can be a concern for musicians who plan to use the flute extensively or in professional settings.

Future of 3D Printed Flutes

The future of 3D printed flutes is promising, with ongoing advancements in 3D printing technology and materials science. As printers become more precise and affordable, and as new materials are developed, the possibilities for creating high-quality, customized flutes will expand. The potential for innovation is vast, from creating flutes with unique sound characteristics to developing educational tools that can help teach music theory and instrument making.

Moreover, the community of makers and musicians involved in 3D printing flutes is growing, which means there will be more shared knowledge, designs, and best practices available for those interested in this field. This collaborative environment can lead to rapid progress and the development of new standards and techniques in 3D printed instrument making.

Applications and Innovations

The applications of 3D printed flutes extend beyond the music industry. They can serve as educational tools in schools, teaching students about music, technology, and innovation. They can also be used in therapeutic settings, providing an accessible means of musical expression for individuals with disabilities. Furthermore, the technology and design principles behind 3D printed flutes can inspire innovations in other fields, such as aerospace, biomedical devices, and consumer products, where complex geometries and customized solutions are valued.

Innovations in 3D printing are also leading to the development of new types of flutes and musical instruments that were previously unimaginable. For instance, flutes with complex internal structures that can produce unique sounds, or instruments that combine different materials to achieve specific acoustic properties. These innovations not only expand the possibilities for musicians but also challenge our understanding of what a musical instrument can be and how it can be made.

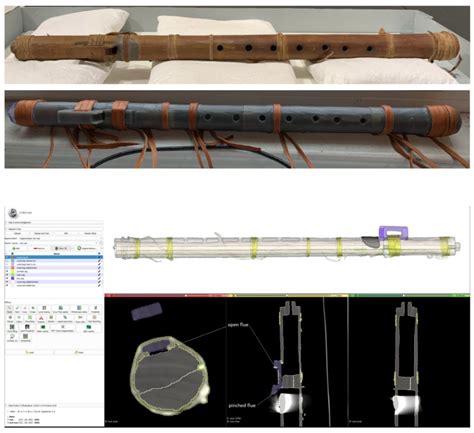

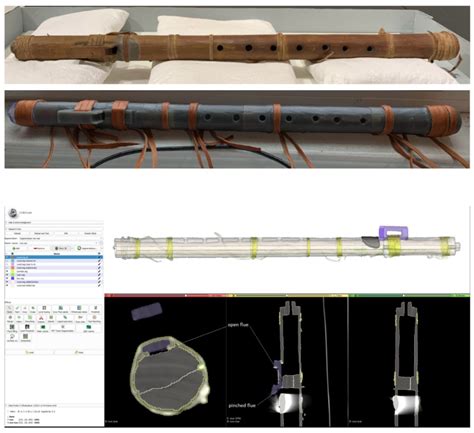

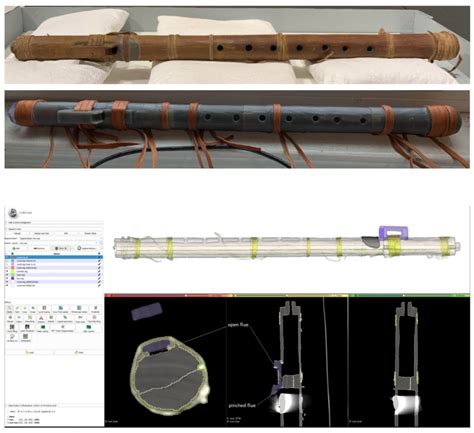

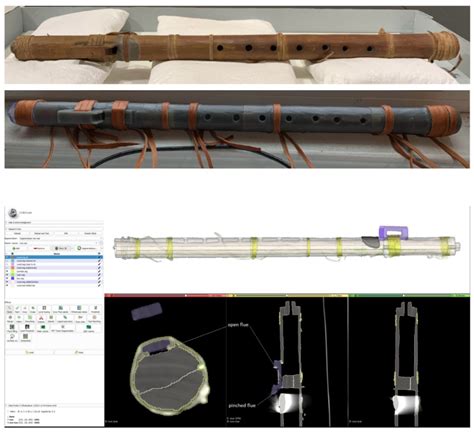

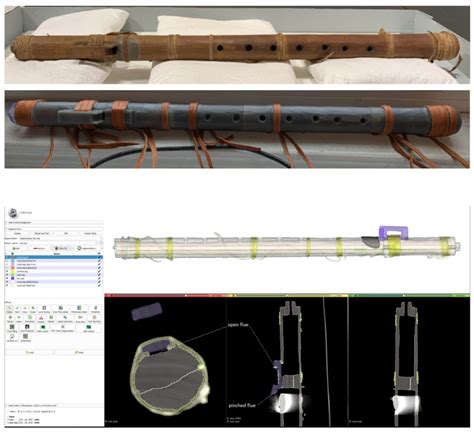

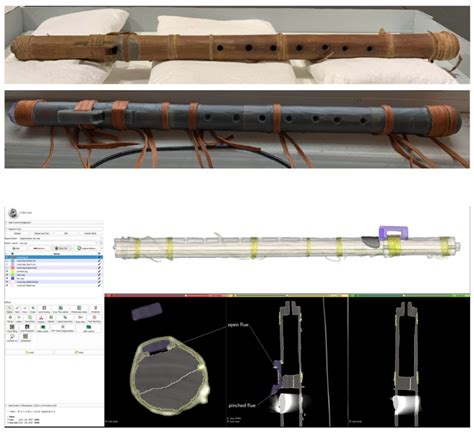

Gallery of 3D Printed Flutes

3D Printed Flute Image Gallery

Frequently Asked Questions

What materials can be used to 3D print a flute?

+Common materials for 3D printing flutes include plastics, metals, and wood-based filaments, each offering different acoustic properties and aesthetic appeals.

How does the sound quality of a 3D printed flute compare to a traditionally made flute?

+The sound quality can vary depending on the material and design. While some 3D printed flutes can produce high-quality sound, achieving a tone comparable to traditionally made flutes can be challenging and may require experimentation.

Can 3D printed flutes be customized?

+Yes, one of the significant advantages of 3D printing flutes is the ease of customization. This allows for adjustments in size, material, and unique features that can enhance playability or sound quality.

What are the potential applications of 3D printed flutes beyond music?

+3D printed flutes can serve as educational tools, be used in therapeutic settings, and inspire innovations in other fields such as aerospace and biomedical devices.

How does the cost of a 3D printed flute compare to a traditionally made flute?

+3D printing can offer a cost-effective solution for those interested in owning a flute, as it reduces production costs and allows for rapid prototyping and production.

In conclusion, the ability to 3D print a flute represents a fascinating intersection of technology, music, and innovation. As this field continues to evolve, we can expect to see not only improvements in the quality and customization of 3D printed flutes but also new applications and innovations that expand our understanding of what is possible with musical instruments. Whether you're a musician, a maker, or simply someone interested in the potential of 3D printing, the world of 3D printed flutes offers a compelling glimpse into the future of music and technology. We invite you to explore this exciting realm, share your experiences, and contribute to the community that is pushing the boundaries of what 3D printed instruments can be.