Intro

The world of 3D printing has revolutionized the way we create and interact with objects, and one of the most exciting applications of this technology is in the realm of miniatures. For years, miniature enthusiasts have been limited to purchasing pre-made models or painstakingly crafting their own by hand. However, with the advent of 3D printing, it is now possible to create intricate, customized, and highly detailed miniatures with ease. In this article, we will delve into the world of 3D printable miniatures models, exploring the benefits, working mechanisms, and steps involved in creating these incredible tiny treasures.

The importance of 3D printable miniatures models cannot be overstated. For gamers, these models can add a new level of realism and immersion to their games, allowing them to fully engage with the world and characters they are playing. For collectors, 3D printed miniatures offer a unique opportunity to own one-of-a-kind, customized models that reflect their individual tastes and preferences. Moreover, the ability to create complex, detailed models with ease has opened up new possibilities for artists, designers, and hobbyists, enabling them to bring their ideas to life in a way that was previously impossible.

As we explore the world of 3D printable miniatures models, it becomes clear that this technology has the potential to democratize the creation and distribution of miniatures. No longer are enthusiasts limited to the models produced by large manufacturers; instead, they can design and print their own models, sharing them with others online or selling them through digital marketplaces. This shift has significant implications for the miniatures industry, enabling smaller, independent creators to reach a global audience and compete with established brands.

Introduction to 3D Printing

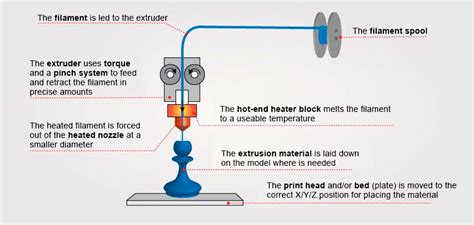

To understand the process of creating 3D printable miniatures models, it is essential to have a basic understanding of 3D printing technology. 3D printing, also known as additive manufacturing, is a process in which digital models are translated into physical objects layer by layer. This is achieved using a 3D printer, which reads the digital design and lays down successive layers of material, such as plastic or resin, to create the final product. The result is a highly detailed, intricate model that can be customized to meet the specific needs of the user.

Benefits of 3D Printable Miniatures Models

So, what are the benefits of 3D printable miniatures models? For starters, these models offer an unprecedented level of customization, enabling users to design and print models that meet their specific needs and preferences. This can include everything from custom characters and creatures to detailed scenery and terrain. Additionally, 3D printed miniatures can be produced quickly and efficiently, reducing the time and cost associated with traditional manufacturing methods. Furthermore, the ability to print models on demand eliminates the need for inventory storage and shipping, making it possible for creators to offer a wide range of models without incurring significant upfront costs.

Working Mechanisms of 3D Printing

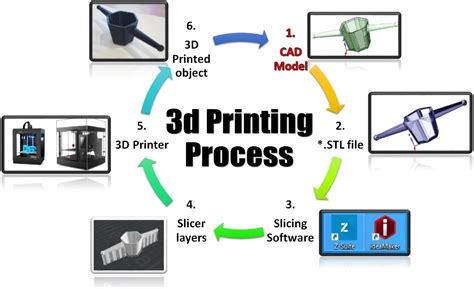

To create 3D printable miniatures models, it is essential to understand the working mechanisms of 3D printing. This involves designing a digital model using computer-aided design (CAD) software or other 3D modeling tools. The digital model is then sliced into thin layers, which are translated into a set of instructions that the 3D printer can understand. The 3D printer reads these instructions and lays down successive layers of material, fusing them together to create the final product. The result is a highly detailed, intricate model that can be customized to meet the specific needs of the user.

Steps Involved in Creating 3D Printable Miniatures Models

So, what are the steps involved in creating 3D printable miniatures models? The process typically begins with designing a digital model using CAD software or other 3D modeling tools. This can involve creating a model from scratch or modifying an existing design to meet the user's specific needs. Once the digital model is complete, it is sliced into thin layers and translated into a set of instructions that the 3D printer can understand. The 3D printer then reads these instructions and lays down successive layers of material, fusing them together to create the final product. Finally, the model is removed from the printer and any necessary post-processing is performed, such as sanding or painting.

Designing 3D Printable Miniatures Models

Designing 3D printable miniatures models requires a combination of technical skills and artistic vision. This involves creating a digital model that is both visually appealing and functional, taking into account the limitations and possibilities of 3D printing technology. The designer must consider factors such as scale, proportion, and detail, as well as the type of material being used and the intended application of the model. Additionally, the designer must ensure that the model is optimized for 3D printing, with features such as supports and drainage channels that enable the model to be printed successfully.

Materials Used in 3D Printing

The materials used in 3D printing are diverse and varied, depending on the specific application and desired properties of the final product. Common materials used in 3D printing include plastics such as ABS and PLA, as well as metals, ceramics, and glass. Each material has its own unique characteristics and advantages, such as strength, durability, and aesthetic appeal. The choice of material will depend on the intended use of the model, as well as the capabilities and limitations of the 3D printer being used.

Post-Processing Techniques

Once a 3D printed model is complete, it may require post-processing techniques to achieve the desired finish and appearance. This can include sanding, painting, and applying coatings or finishes to protect the model and enhance its durability. Post-processing techniques can also be used to add details and textures to the model, such as eyes, hair, or clothing. The specific post-processing techniques used will depend on the material and intended use of the model, as well as the desired level of detail and realism.

Applications of 3D Printable Miniatures Models

The applications of 3D printable miniatures models are diverse and varied, ranging from gaming and collectibles to education and research. For gamers, 3D printed miniatures can add a new level of realism and immersion to their games, enabling them to fully engage with the world and characters they are playing. For collectors, 3D printed miniatures offer a unique opportunity to own one-of-a-kind, customized models that reflect their individual tastes and preferences. Additionally, 3D printed miniatures can be used in educational settings to teach concepts such as history, science, and art, as well as in research applications such as prototyping and testing.

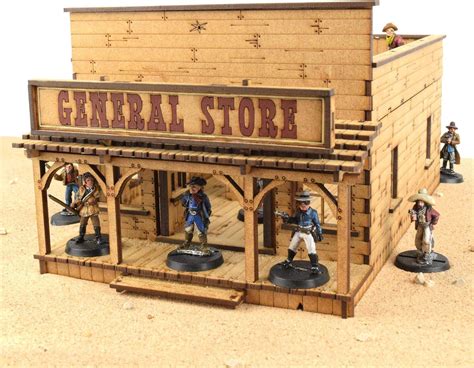

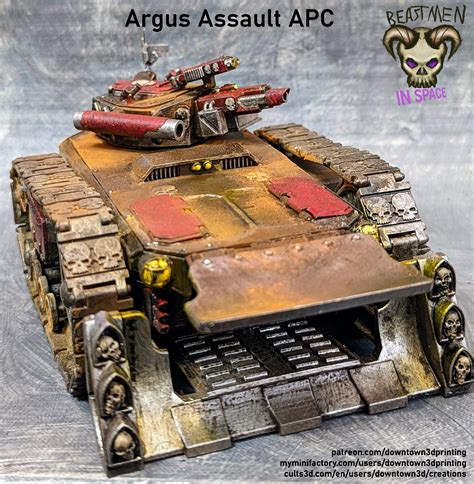

Gallery of 3D Printable Miniatures Models

3D Printable Miniatures Models Image Gallery

What is 3D printing and how does it work?

+3D printing, also known as additive manufacturing, is a process in which digital models are translated into physical objects layer by layer. This is achieved using a 3D printer, which reads the digital design and lays down successive layers of material, such as plastic or resin, to create the final product.

What are the benefits of 3D printable miniatures models?

+The benefits of 3D printable miniatures models include customization, speed, and efficiency. These models can be designed and printed quickly, reducing the time and cost associated with traditional manufacturing methods. Additionally, 3D printed miniatures can be produced on demand, eliminating the need for inventory storage and shipping.

What materials can be used in 3D printing?

+The materials used in 3D printing are diverse and varied, depending on the specific application and desired properties of the final product. Common materials used in 3D printing include plastics such as ABS and PLA, as well as metals, ceramics, and glass. Each material has its own unique characteristics and advantages, such as strength, durability, and aesthetic appeal.

What are the applications of 3D printable miniatures models?

+The applications of 3D printable miniatures models are diverse and varied, ranging from gaming and collectibles to education and research. For gamers, 3D printed miniatures can add a new level of realism and immersion to their games, enabling them to fully engage with the world and characters they are playing. For collectors, 3D printed miniatures offer a unique opportunity to own one-of-a-kind, customized models that reflect their individual tastes and preferences.

How do I get started with 3D printing and creating my own miniatures models?

+To get started with 3D printing and creating your own miniatures models, you will need a 3D printer and some basic knowledge of 3D modeling software. You can start by designing simple models and experimenting with different materials and techniques. There are also many online resources and communities available to help you learn and improve your skills.

In conclusion, 3D printable miniatures models offer a wide range of benefits and opportunities for enthusiasts, collectors, and creators. With the ability to design and print customized models quickly and efficiently, 3D printing has democratized the creation and distribution of miniatures, enabling smaller, independent creators to reach a global audience and compete with established brands. Whether you are a gamer, collector, or simply someone who appreciates the art and craftsmanship of miniatures, 3D printable miniatures models are definitely worth exploring. So why not give it a try and see what amazing creations you can come up with? Share your thoughts and experiences with us in the comments below, and don't forget to share this article with your friends and fellow enthusiasts.