Intro

The world of 3D printing has revolutionized the way we create and interact with objects, and one of the most exciting applications of this technology is in the realm of miniature models. 3D printable minis have become increasingly popular among hobbyists, gamers, and collectors, offering a new level of detail and customization that was previously impossible to achieve. In this article, we will delve into the world of 3D printable minis, exploring their benefits, working mechanisms, and the steps involved in creating and printing these tiny masterpieces.

The rise of 3D printable minis can be attributed to the growing accessibility of 3D printing technology, which has made it possible for individuals to create complex models with ease. The internet has also played a significant role in the proliferation of 3D printable minis, with online communities and marketplaces providing a platform for designers to share and sell their creations. As a result, the range of available 3D printable minis has expanded exponentially, catering to diverse interests and hobbies, from fantasy creatures to historical figures, and from sci-fi characters to mythical beasts.

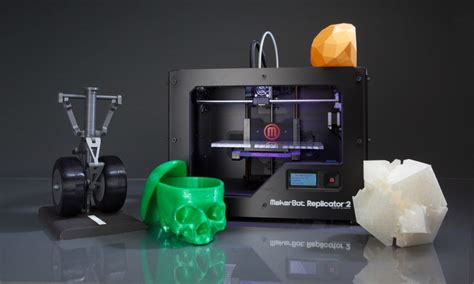

The benefits of 3D printable minis are numerous, and they have transformed the way we engage with miniature models. For one, they offer unparalleled customization options, allowing users to modify and personalize their models to suit their preferences. This level of flexibility is particularly appealing to gamers, who can create bespoke characters and scenery to enhance their gaming experiences. Additionally, 3D printable minis have made it possible for artists and designers to create intricate and complex models that would be impossible to produce using traditional manufacturing methods.

Introduction to 3D Printing

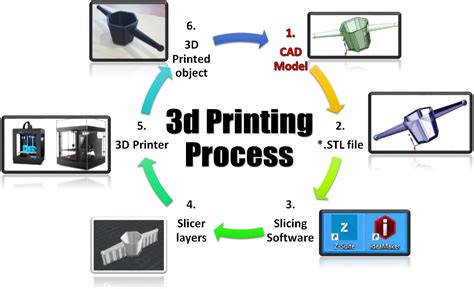

To understand the world of 3D printable minis, it is essential to grasp the basics of 3D printing. This technology involves the layer-by-layer creation of objects using a variety of materials, such as plastics, metals, and ceramics. The 3D printing process typically begins with the design of a digital model, which is then sliced into thin layers and sent to a 3D printer. The printer reads the design file and deposits the material, layer by layer, to create the final object. The quality and resolution of the printed object depend on various factors, including the type of printer, the material used, and the settings employed during the printing process.

Benefits of 3D Printable Minis

The benefits of 3D printable minis are numerous and have transformed the way we engage with miniature models. Some of the key advantages include:

- Unparalleled customization options, allowing users to modify and personalize their models to suit their preferences

- The ability to create intricate and complex models that would be impossible to produce using traditional manufacturing methods

- Enhanced detail and accuracy, enabling the creation of highly realistic models

- Cost-effectiveness, as 3D printing eliminates the need for expensive molds and tooling

- Rapid production, allowing for quick turnaround times and fast delivery of printed models

Working Mechanisms of 3D Printable Minis

The working mechanisms of 3D printable minis involve several key components, including:

- Digital design: The creation of a digital model using computer-aided design (CAD) software or other 3D modeling tools

- Slicing: The division of the digital model into thin layers, which are then sent to a 3D printer

- Printing: The layer-by-layer creation of the object using a 3D printer

- Post-processing: The removal of support material, sanding, and painting of the printed model to achieve the desired finish

Steps Involved in Creating 3D Printable Minis

The steps involved in creating 3D printable minis include:

- Design: The creation of a digital model using CAD software or other 3D modeling tools

- Testing: The verification of the digital model to ensure that it is printable and free of errors

- Slicing: The division of the digital model into thin layers, which are then sent to a 3D printer

- Printing: The layer-by-layer creation of the object using a 3D printer

- Post-processing: The removal of support material, sanding, and painting of the printed model to achieve the desired finish

Applications of 3D Printable Minis

The applications of 3D printable minis are diverse and continue to expand as the technology advances. Some of the key areas where 3D printable minis are being used include:

- Gaming: The creation of bespoke characters and scenery to enhance gaming experiences

- Collecting: The production of limited-edition models and figurines for collectors

- Education: The use of 3D printable minis to create interactive and engaging learning materials

- Art: The creation of intricate and complex models for artistic expression and exhibition

Challenges and Limitations of 3D Printable Minis

While 3D printable minis offer many benefits and opportunities, there are also challenges and limitations to consider. Some of the key issues include:

- Quality and resolution: The quality and resolution of printed models can vary depending on the type of printer and material used

- Cost: The cost of 3D printing equipment and materials can be prohibitively expensive for some users

- Complexity: The creation of complex models can be time-consuming and require significant expertise

- Intellectual property: The use of 3D printing to create models of copyrighted or trademarked characters and designs can raise intellectual property concerns

Future of 3D Printable Minis

The future of 3D printable minis is exciting and full of possibilities. As the technology continues to advance, we can expect to see improvements in quality, resolution, and cost-effectiveness. The development of new materials and printing techniques will also expand the range of applications and possibilities for 3D printable minis. Additionally, the growth of online communities and marketplaces will provide more opportunities for designers and users to share and collaborate on 3D printing projects.

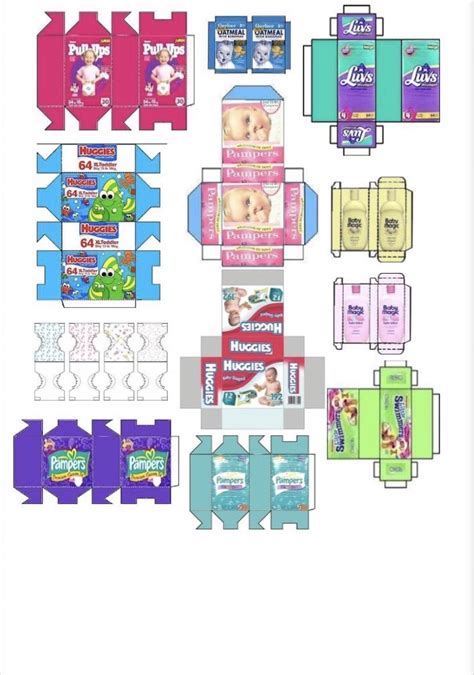

Gallery of 3D Printable Minis

3D Printable Minis Image Gallery

What is 3D printing?

+3D printing is a technology that involves the layer-by-layer creation of objects using a variety of materials, such as plastics, metals, and ceramics.

What are the benefits of 3D printable minis?

+The benefits of 3D printable minis include unparalleled customization options, the ability to create intricate and complex models, enhanced detail and accuracy, cost-effectiveness, and rapid production.

What are the applications of 3D printable minis?

+The applications of 3D printable minis include gaming, collecting, education, art, and more.

What are the challenges and limitations of 3D printable minis?

+The challenges and limitations of 3D printable minis include quality and resolution, cost, complexity, and intellectual property concerns.

What is the future of 3D printable minis?

+The future of 3D printable minis is exciting and full of possibilities, with advancements in technology, materials, and applications expected to continue and expand.

In conclusion, 3D printable minis have revolutionized the world of miniature models, offering unparalleled customization options, intricate details, and rapid production. As the technology continues to advance, we can expect to see even more exciting developments and applications in the future. Whether you are a gamer, collector, artist, or educator, 3D printable minis have the potential to enhance and transform your experiences. We invite you to explore the world of 3D printable minis, share your thoughts and experiences, and join the community of enthusiasts and creators who are pushing the boundaries of what is possible with this technology.