Intro

Discover 3D printable shapes, including geometric models, architectural designs, and mathematical patterns, to create complex structures with precision and accuracy, using CAD software and 3D printing technology for innovative modeling and prototyping solutions.

The world of 3D printing has opened up a vast array of possibilities for creators and innovators alike. One of the most exciting aspects of this technology is the ability to design and print complex shapes that were previously impossible to produce using traditional manufacturing methods. 3D printable shapes have revolutionized various industries, from art and design to engineering and architecture. In this article, we will delve into the importance of 3D printable shapes, their benefits, and the various ways they are being used.

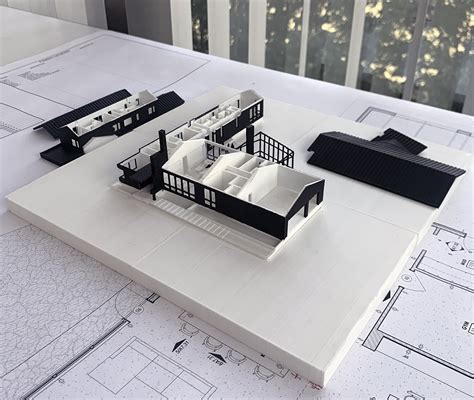

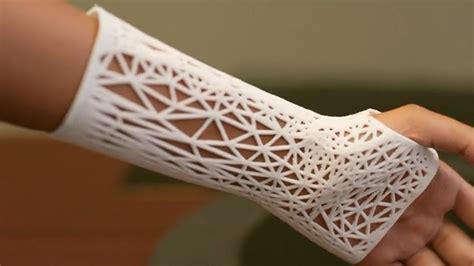

The ability to create complex shapes with precision and accuracy has enabled designers and engineers to push the boundaries of innovation. 3D printable shapes have made it possible to produce customized products, such as prosthetic limbs, implants, and dental implants, that are tailored to individual needs. The use of 3D printing technology has also enabled the creation of complex architectural models, allowing architects to visualize and test their designs before construction begins.

The benefits of 3D printable shapes are numerous. They enable the rapid prototyping of products, reducing the time and cost associated with traditional manufacturing methods. 3D printing also allows for the creation of complex geometries and structures that cannot be produced using traditional methods. This has led to the development of new materials and products with unique properties, such as lightweight yet strong structures.

Introduction to 3D Printable Shapes

3D printable shapes are designed using computer-aided design (CAD) software or other 3D modeling tools. These designs are then exported as digital files, which are read by 3D printers to produce the physical object. The process of 3D printing involves layering materials, such as plastics, metals, or ceramics, to create the desired shape. The accuracy and precision of 3D printing technology have made it possible to produce complex shapes with intricate details and structures.

Benefits of 3D Printable Shapes

The benefits of 3D printable shapes are numerous. Some of the key advantages include:

- Rapid prototyping: 3D printing enables the rapid production of prototypes, reducing the time and cost associated with traditional manufacturing methods.

- Complex geometries: 3D printing allows for the creation of complex geometries and structures that cannot be produced using traditional methods.

- Customization: 3D printing enables the production of customized products, such as prosthetic limbs, implants, and dental implants, that are tailored to individual needs.

- Cost-effective: 3D printing can be a cost-effective method of production, especially for small batches or one-off products.

Applications of 3D Printable Shapes

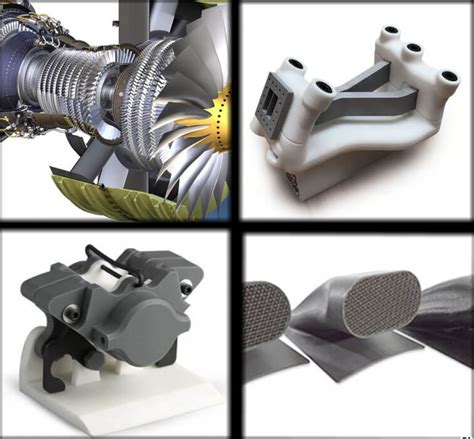

3D printable shapes have a wide range of applications across various industries. Some of the key areas where 3D printing is being used include:

- Aerospace: 3D printing is being used to produce lightweight yet strong structures for aircraft and spacecraft.

- Automotive: 3D printing is being used to produce customized car parts, such as dashboard trim and engine components.

- Medical: 3D printing is being used to produce customized prosthetic limbs, implants, and dental implants.

- Architecture: 3D printing is being used to produce complex architectural models, allowing architects to visualize and test their designs before construction begins.

Designing 3D Printable Shapes

Designing 3D printable shapes requires a good understanding of 3D modeling software and the principles of 3D printing. Some of the key considerations when designing 3D printable shapes include:

- Material selection: The choice of material will depend on the intended application and the properties required.

- Layer thickness: The layer thickness will affect the accuracy and precision of the final product.

- Support structures: Support structures may be required to prevent the object from collapsing or deforming during printing.

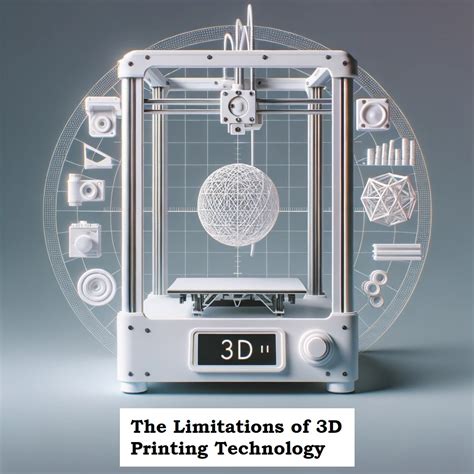

Challenges and Limitations of 3D Printable Shapes

While 3D printable shapes offer many benefits, there are also some challenges and limitations to consider. Some of the key challenges include:

- Material limitations: The properties of the materials used in 3D printing can limit the performance and durability of the final product.

- Scalability: 3D printing can be a time-consuming process, making it difficult to scale up production.

- Cost: While 3D printing can be a cost-effective method of production, the cost of the equipment and materials can be high.

Future of 3D Printable Shapes

The future of 3D printable shapes is exciting and rapidly evolving. Some of the key trends and developments include:

- Advances in materials: New materials are being developed that offer improved properties and performance.

- Improvements in printing technology: Advances in printing technology are enabling faster and more accurate printing.

- Increased adoption: 3D printing is being adopted across a wide range of industries, from aerospace to medical.

Gallery of 3D Printable Shapes

3D Printable Shapes Image Gallery

What are 3D printable shapes?

+3D printable shapes are digital designs that can be produced using 3D printing technology. They can be used to create a wide range of products, from prosthetic limbs to architectural models.

What are the benefits of 3D printable shapes?

+The benefits of 3D printable shapes include rapid prototyping, complex geometries, customization, and cost-effectiveness. They can be used to produce products with unique properties and can be tailored to individual needs.

What are the challenges and limitations of 3D printable shapes?

+The challenges and limitations of 3D printable shapes include material limitations, scalability, and cost. The properties of the materials used in 3D printing can limit the performance and durability of the final product, and the cost of the equipment and materials can be high.

In summary, 3D printable shapes have revolutionized various industries, from art and design to engineering and architecture. They offer numerous benefits, including rapid prototyping, complex geometries, customization, and cost-effectiveness. While there are challenges and limitations to consider, the future of 3D printable shapes is exciting and rapidly evolving. We invite you to share your thoughts and experiences with 3D printing and explore the endless possibilities of this technology. Whether you are a designer, engineer, or simply a curious individual, we encourage you to join the conversation and discover the incredible world of 3D printable shapes.