Intro

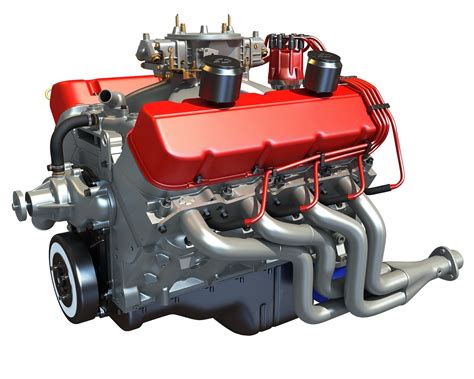

Explore a highly detailed 3D printable V8 engine model, featuring intricate designs, movable parts, and realistic scaled replicas, perfect for automotive enthusiasts and 3D printing hobbyists.

The world of 3D printing has revolutionized the way we create and design objects, allowing us to bring complex ideas to life with unprecedented precision and accuracy. One of the most fascinating applications of 3D printing is in the creation of scale models, particularly when it comes to intricate and detailed designs like a V8 engine. For car enthusiasts and engineers alike, a 3D printable V8 engine model is not just a novelty but a highly educational and engaging tool that can help deepen understanding of how these powerful engines work. In this article, we'll delve into the importance of such models, their benefits, and the process of creating them, as well as explore the educational and hobbyist aspects they cater to.

The complexity and beauty of a V8 engine lie in its design and functionality. With eight cylinders arranged in a V configuration, this type of engine is known for its power and efficiency. For educational purposes, having a detailed model can significantly enhance the learning experience, allowing students to visualize and understand the spatial relationships and mechanisms involved. Moreover, for hobbyists and car enthusiasts, a 3D printed V8 engine model offers a unique opportunity to own and display a highly detailed replica of an engine, which can be both decorative and informative.

The process of creating a 3D printable V8 engine model involves several steps, starting from design to the actual printing. The design phase is crucial and requires a deep understanding of the engine's components and their relationships. Software such as CAD (Computer-Aided Design) is used to create a digital model of the engine, ensuring that all parts are accurately represented and can be assembled correctly. Once the design is complete, it's prepared for 3D printing, which involves slicing the model into layers that the printer can understand and print layer by layer.

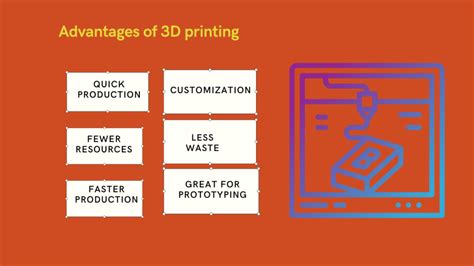

Benefits of 3D Printable Models

The benefits of 3D printable models, such as a V8 engine, are multifaceted. Firstly, they offer a cost-effective way to create complex designs without the need for extensive tooling or manufacturing setups. This makes them particularly appealing for educational institutions and hobbyists who may not have access to large budgets. Secondly, 3D printing allows for a high degree of customization and detail, enabling the creation of models that are not only visually accurate but also functional to some extent. For educators, this means being able to create models that can demonstrate specific principles or mechanisms in action, enhancing the learning experience.

Moreover, 3D printable models contribute to sustainability by reducing waste and the need for physical prototypes in the design phase. Designers and engineers can test and refine their designs digitally and then print out the final model, reducing the environmental impact of the design process. This aspect is particularly important in industries where prototyping is a significant part of the product development cycle.

Designing a 3D Printable V8 Engine Model

Designing a 3D printable V8 engine model requires meticulous attention to detail and a thorough understanding of the engine's mechanics. The process begins with researching the engine's specifications and gathering reference images or diagrams to ensure accuracy. CAD software is then used to create a digital model, starting with the basic components such as the cylinders, pistons, crankshaft, and camshafts, before moving on to more complex systems like the cooling and ignition systems.

One of the challenges in designing such a model is balancing detail with printability. Too much detail can make the model difficult to print, especially if the features are very small or intricate. On the other hand, too little detail can result in a model that lacks realism and educational value. Therefore, designers must carefully select which features to include and how to represent them in a way that is both accurate and printable.

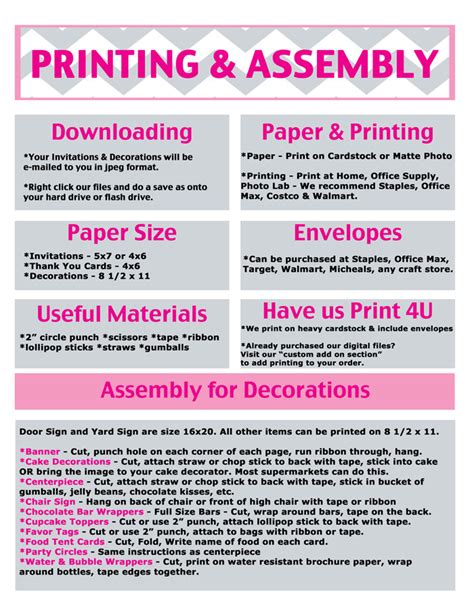

Printing and Assembly

The printing process for a 3D model of a V8 engine can be quite lengthy, depending on the size of the model and the resolution desired. Most 3D printers used for such projects are FFF (Fused Filament Fabrication) printers, which work by extruding melted plastic layer by layer to build up the model. The choice of filament is important, with common choices including PLA (Polylactic Acid) for its ease of use and ABS (Acrylonitrile Butadiene Styrene) for its durability.

Once all the parts are printed, the next step is assembly. This can be a complex process, requiring patience and attention to detail to ensure that all components fit together correctly. The model may require additional post-processing, such as sanding or painting, to enhance its appearance and durability.

Educational Applications

For educational purposes, a 3D printable V8 engine model can be a valuable tool. It allows students to explore the engine's components and understand how they interact in a way that is both engaging and interactive. Such models can be particularly useful in automotive and mechanical engineering courses, where understanding engine mechanics is crucial. Moreover, the process of designing and printing the model itself can be a learning experience, teaching students about design principles, materials science, and manufacturing technologies.

Hobbyist and Collector Interest

Beyond its educational value, a 3D printed V8 engine model can also appeal to hobbyists and collectors. For car enthusiasts, such a model offers a unique opportunity to own a highly detailed and accurate replica of an engine, which can be displayed and admired. The customization options available through 3D printing also mean that models can be tailored to specific interests, such as scale, color, or even the addition of moving parts to simulate engine operation.

Gallery of 3D Printable V8 Engine Models

3D Printable V8 Engine Models Gallery

Frequently Asked Questions

What is the purpose of a 3D printable V8 engine model?

+The purpose of a 3D printable V8 engine model is to provide a detailed and educational representation of a V8 engine, suitable for both educational purposes and hobbyist display.

How is a 3D printable V8 engine model designed?

+A 3D printable V8 engine model is designed using CAD software, which allows for the creation of a highly detailed digital model before printing.

What are the benefits of 3D printing a V8 engine model?

+The benefits include cost-effectiveness, customization options, and the ability to create complex designs with high accuracy and detail.

Can a 3D printed V8 engine model be customized?

+Yes, one of the advantages of 3D printing is the ability to customize models according to specific needs or preferences, including scale, color, and level of detail.

What materials are used for printing a 3D V8 engine model?

+Common materials include PLA and ABS, chosen for their ease of use, durability, and the finish they provide to the model.

In conclusion, a 3D printable V8 engine model represents the intersection of technology, education, and hobbyist interests, offering a unique blend of complexity, detail, and customization. Whether for educational purposes, to satisfy a hobbyist's passion, or as a collector's item, such models showcase the potential of 3D printing to bring intricate designs to life. As technology continues to evolve, we can expect even more sophisticated and detailed models to emerge, further expanding the possibilities for learning, display, and admiration. We invite readers to share their experiences with 3D printing and model making, and to explore the vast community of enthusiasts and experts who are pushing the boundaries of what is possible with these technologies.