Intro

Discover 3D print water pump designs, tutorials, and DIY projects, featuring innovative additive manufacturing techniques, fluid dynamics, and precision engineering for efficient water pumping systems.

The world of 3D printing has revolutionized the way we create and innovate, allowing us to bring complex ideas to life with unprecedented precision and accuracy. One of the most exciting applications of 3D printing is in the field of engineering, where it is being used to create functional prototypes and end-use products, such as water pumps. In this article, we will delve into the world of 3D printed water pumps, exploring their benefits, working mechanisms, and the steps involved in creating them.

The importance of water pumps cannot be overstated, as they play a crucial role in various industries, including agriculture, construction, and manufacturing. Traditional water pumps are often heavy, expensive, and difficult to maintain, which is where 3D printing comes in. By leveraging the power of additive manufacturing, engineers and designers can create customized water pumps that are lighter, more efficient, and cost-effective. With the ability to produce complex geometries and internal structures, 3D printing enables the creation of water pumps with improved performance and reduced energy consumption.

As we explore the world of 3D printed water pumps, it becomes clear that this technology has the potential to transform the way we approach water management and conservation. From irrigation systems to industrial processes, 3D printed water pumps can help reduce waste, increase efficiency, and promote sustainability. Whether you are an engineer, designer, or simply someone interested in innovative technologies, this article will provide you with a comprehensive overview of 3D printed water pumps and their exciting possibilities.

Introduction to 3D Printed Water Pumps

Benefits of 3D Printed Water Pumps

The advantages of 3D printed water pumps are numerous, including: * Reduced weight: 3D printed water pumps can be designed with optimized internal structures, reducing material usage and weight. * Increased efficiency: Customized designs and internal geometries can improve pump performance, reducing energy consumption and increasing flow rates. * Improved performance: 3D printing enables the creation of complex internal structures, such as impellers and volutes, which can enhance pump performance and reduce wear and tear. * Cost-effective: 3D printing can reduce production costs by minimizing material waste and enabling the creation of customized designs.Working Mechanisms of 3D Printed Water Pumps

Steps Involved in Creating 3D Printed Water Pumps

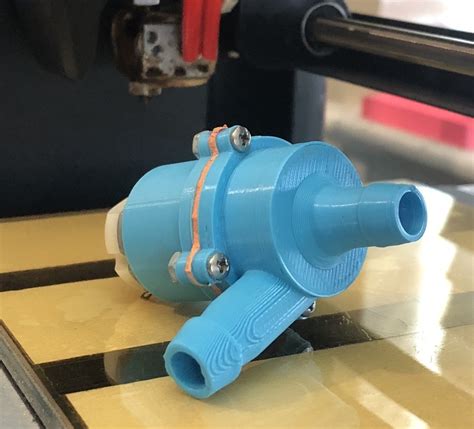

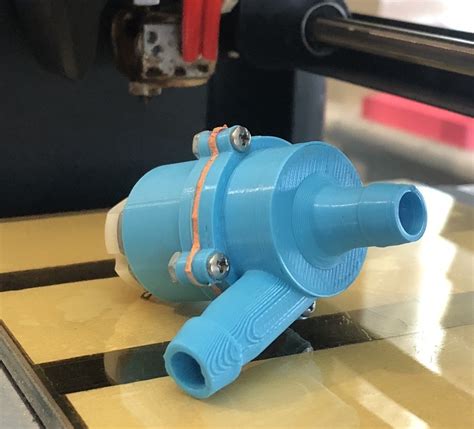

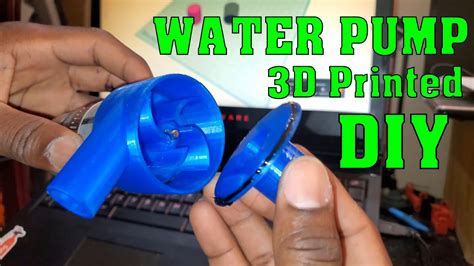

The process of creating 3D printed water pumps involves several steps, including: 1. Design: Creating a customized design using computer-aided design (CAD) software or other 3D modeling tools. 2. Material selection: Choosing a suitable material for the pump, such as plastics, metals, or ceramics, depending on the application and required properties. 3. 3D printing: Building the pump using an additive manufacturing process, such as fused deposition modeling (FDM) or stereolithography (SLA). 4. Post-processing: Removing support material, sanding, and applying coatings or finishes to enhance the pump's performance and durability. 5. Testing and validation: Evaluating the pump's performance, flow rates, and pressure to ensure it meets the required specifications and standards.Applications of 3D Printed Water Pumps

Challenges and Limitations of 3D Printed Water Pumps

While 3D printed water pumps offer numerous benefits, there are also challenges and limitations to consider, including: * Material properties: The properties of 3D printed materials can vary depending on the printing process, material, and post-processing techniques. * Scalability: 3D printing can be a time-consuming and expensive process, making it challenging to produce large quantities of water pumps. * Regulation: The use of 3D printed water pumps may be subject to regulatory requirements, such as safety standards and certification.Future Developments and Innovations

Gallery of 3D Printed Water Pumps

3D Printed Water Pump Image Gallery

Frequently Asked Questions

What are the benefits of 3D printed water pumps?

+The benefits of 3D printed water pumps include reduced weight, increased efficiency, and improved performance, making them an attractive option for various industries and applications.

How do 3D printed water pumps work?

+3D printed water pumps work by converting mechanical energy into hydraulic energy, using components such as impellers, volutes, and shafts to create a pressure difference and draw fluid into the pump.

What are the challenges and limitations of 3D printed water pumps?

+The challenges and limitations of 3D printed water pumps include material properties, scalability, and regulation, which can affect their performance, cost, and adoption in various industries and applications.

As we conclude our exploration of 3D printed water pumps, it is clear that this technology has the potential to transform the way we approach water management and conservation. With its numerous benefits, improved performance, and reduced environmental impact, 3D printed water pumps are an exciting innovation that can help shape a more sustainable future. We invite you to share your thoughts, ask questions, and explore the possibilities of 3D printed water pumps, and we look forward to continuing the conversation on this innovative topic.