Intro

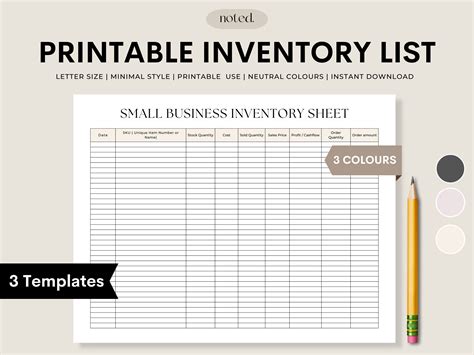

Get organized with 5 free inventory sheets, featuring stock management templates, inventory tracking, and warehouse management tools to streamline logistics and optimize supply chain operations.

Effective inventory management is crucial for businesses of all sizes, as it helps in maintaining a balance between stock levels and customer demand. One of the simplest and most effective tools for managing inventory is an inventory sheet. An inventory sheet is a document used to track and record the quantity of goods or materials in stock. In this article, we will discuss the importance of inventory sheets and provide 5 free inventory sheet templates that businesses can use to streamline their inventory management processes.

Inventory management involves a range of activities, including monitoring stock levels, tracking inventory movements, and optimizing inventory levels to meet customer demand. Without an effective inventory management system, businesses can face a range of problems, including stockouts, overstocking, and wasted resources. Inventory sheets are an essential part of any inventory management system, as they provide a clear and concise record of the goods or materials in stock.

Using inventory sheets can help businesses in several ways. Firstly, they provide a centralized record of inventory levels, making it easier to track stock movements and identify trends. Secondly, they help businesses to avoid stockouts and overstocking, by providing a clear picture of the quantity of goods or materials in stock. Finally, inventory sheets can help businesses to optimize their inventory levels, by identifying areas where stock levels can be reduced or increased.

Benefits of Using Inventory Sheets

The benefits of using inventory sheets are numerous. Some of the key benefits include improved inventory accuracy, reduced stockouts and overstocking, and increased efficiency. Inventory sheets can also help businesses to identify areas where inventory levels can be optimized, resulting in cost savings and improved profitability. Additionally, inventory sheets can provide a clear and concise record of inventory levels, making it easier to track stock movements and identify trends.

Types of Inventory Sheets

There are several types of inventory sheets that businesses can use, depending on their specific needs and requirements. Some common types of inventory sheets include basic inventory sheets, stock inventory sheets, and warehouse inventory sheets. Basic inventory sheets are simple documents that list the quantity of goods or materials in stock, while stock inventory sheets provide a more detailed record of inventory levels, including information on stock movements and inventory valuations. Warehouse inventory sheets are used to track inventory levels in warehouses and distribution centers, and typically include information on inventory storage and handling.5 Free Inventory Sheet Templates

Here are 5 free inventory sheet templates that businesses can use to streamline their inventory management processes:

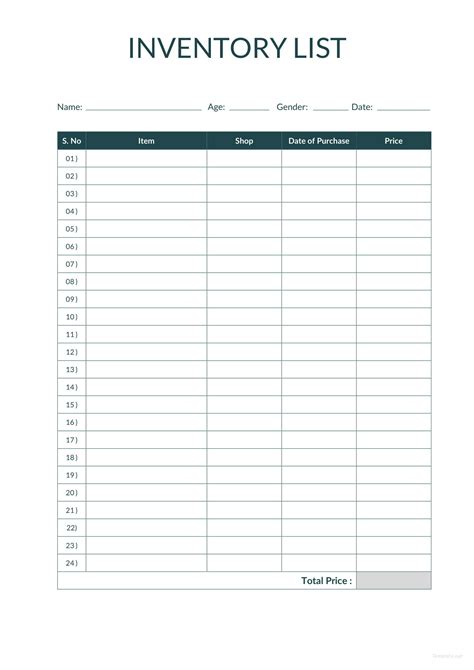

- Basic Inventory Sheet: This template provides a simple and easy-to-use format for tracking inventory levels. It includes columns for item description, quantity, and unit price, making it easy to calculate the total value of inventory.

- Stock Inventory Sheet: This template provides a more detailed record of inventory levels, including information on stock movements and inventory valuations. It includes columns for item description, quantity, unit price, and total value, as well as a section for tracking stock movements.

- Warehouse Inventory Sheet: This template is designed for use in warehouses and distribution centers, and includes information on inventory storage and handling. It includes columns for item description, quantity, unit price, and storage location, as well as a section for tracking inventory movements.

- Perpetual Inventory Sheet: This template is designed for use in businesses that use a perpetual inventory system, where inventory levels are updated continuously. It includes columns for item description, quantity, unit price, and total value, as well as a section for tracking inventory movements.

- Periodic Inventory Sheet: This template is designed for use in businesses that use a periodic inventory system, where inventory levels are updated at regular intervals. It includes columns for item description, quantity, unit price, and total value, as well as a section for tracking inventory movements.

How to Use Inventory Sheets

Using inventory sheets is a straightforward process that involves several steps. Firstly, businesses need to identify the type of inventory sheet that best meets their needs and requirements. Secondly, they need to set up the inventory sheet, by entering information on the goods or materials in stock. Thirdly, they need to update the inventory sheet regularly, by tracking stock movements and inventory valuations. Finally, they need to review the inventory sheet regularly, to identify areas where inventory levels can be optimized and to make informed decisions about inventory management.Best Practices for Inventory Management

There are several best practices that businesses can follow to optimize their inventory management processes. Some of the key best practices include:

- Monitor inventory levels regularly: This involves tracking stock movements and inventory valuations, to identify areas where inventory levels can be optimized.

- Use inventory management software: This can help businesses to streamline their inventory management processes, by providing a centralized record of inventory levels and automating tasks such as tracking stock movements and inventory valuations.

- Implement a just-in-time inventory system: This involves ordering inventory just in time to meet customer demand, rather than holding large quantities of inventory in stock.

- Use inventory sheets: This can help businesses to track inventory levels and identify areas where inventory levels can be optimized.

Common Inventory Management Mistakes

There are several common inventory management mistakes that businesses can make, including:- Overstocking: This involves holding too much inventory in stock, which can result in wasted resources and reduced profitability.

- Understocking: This involves holding too little inventory in stock, which can result in stockouts and lost sales.

- Inaccurate inventory tracking: This involves failing to track inventory levels accurately, which can result in inventory discrepancies and reduced profitability.

- Failing to optimize inventory levels: This involves failing to identify areas where inventory levels can be optimized, which can result in reduced profitability and wasted resources.

Inventory Management Tools and Techniques

There are several inventory management tools and techniques that businesses can use to optimize their inventory management processes. Some of the key tools and techniques include:

- Inventory management software: This can help businesses to streamline their inventory management processes, by providing a centralized record of inventory levels and automating tasks such as tracking stock movements and inventory valuations.

- Barcoding and RFID: This can help businesses to track inventory levels accurately, by providing a unique identifier for each item in stock.

- Inventory forecasting: This involves using historical data and statistical models to forecast future inventory demand, and can help businesses to optimize their inventory levels.

- Supply chain management: This involves managing the flow of goods and services from raw materials to end customers, and can help businesses to optimize their inventory management processes.

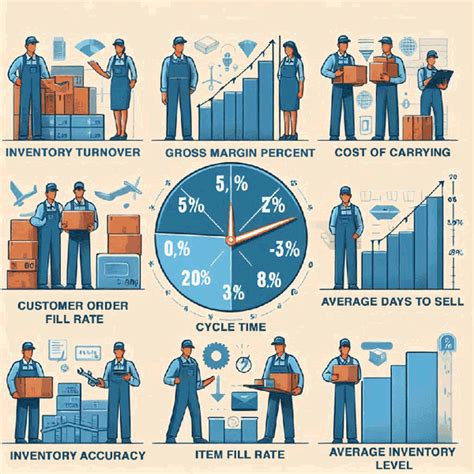

Inventory Management Metrics and KPIs

There are several inventory management metrics and KPIs that businesses can use to measure the effectiveness of their inventory management processes. Some of the key metrics and KPIs include:- Inventory turnover: This measures the number of times that inventory is sold and replaced within a given period, and can help businesses to identify areas where inventory levels can be optimized.

- Inventory days: This measures the average number of days that inventory is held in stock, and can help businesses to identify areas where inventory levels can be optimized.

- Fill rate: This measures the percentage of customer orders that are filled from existing inventory, and can help businesses to identify areas where inventory levels can be optimized.

- Inventory accuracy: This measures the accuracy of inventory tracking, and can help businesses to identify areas where inventory levels can be optimized.

Inventory Management Image Gallery

What is an inventory sheet?

+An inventory sheet is a document used to track and record the quantity of goods or materials in stock.

Why is inventory management important?

+Inventory management is important because it helps businesses to maintain a balance between stock levels and customer demand, and to optimize their inventory levels to reduce costs and improve profitability.

What are some common inventory management mistakes?

+Some common inventory management mistakes include overstocking, understocking, inaccurate inventory tracking, and failing to optimize inventory levels.

What are some best practices for inventory management?

+Some best practices for inventory management include monitoring inventory levels regularly, using inventory management software, implementing a just-in-time inventory system, and using inventory sheets.

What are some inventory management tools and techniques?

+Some inventory management tools and techniques include inventory management software, barcoding and RFID, inventory forecasting, and supply chain management.

We hope that this article has provided you with a comprehensive overview of inventory sheets and their importance in inventory management. By using the 5 free inventory sheet templates provided, businesses can streamline their inventory management processes and optimize their inventory levels to reduce costs and improve profitability. Remember to monitor inventory levels regularly, use inventory management software, implement a just-in-time inventory system, and use inventory sheets to achieve effective inventory management. If you have any questions or need further assistance, please don't hesitate to comment below or share this article with others.