Intro

Boost labeling efficiency with 5 Dymo Label Tips, including organization, font styles, and printer maintenance, to optimize label maker usage and improve productivity with custom labels, label templates, and more.

The world of labeling can be a complex and often overwhelming place, especially for those who are new to using labels in their personal or professional lives. One of the most popular and user-friendly labeling solutions on the market is the Dymo label, which offers a wide range of products and tools to help individuals and businesses create and print their own labels. In this article, we will explore five Dymo label tips that can help you get the most out of your labeling experience.

Labeling is an essential part of many different industries and aspects of life, from organizing files and folders to creating signs and labels for products and packaging. With the right tools and techniques, labeling can be a quick and easy process that helps to increase productivity and efficiency. The Dymo label is one of the most popular labeling solutions on the market, and for good reason - it is easy to use, versatile, and offers a wide range of features and benefits.

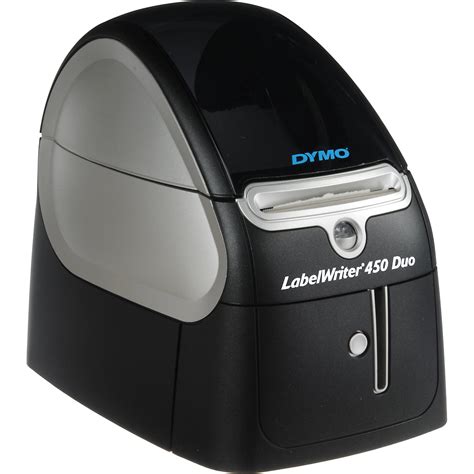

One of the key benefits of using Dymo labels is the ability to create custom labels that meet your specific needs and requirements. Whether you are looking to create labels for a small business or a large corporation, Dymo offers a wide range of products and tools that can help you to create professional-looking labels that are both durable and long-lasting. From label makers and printers to labels and accessories, Dymo has everything you need to create and print your own labels.

Understanding Dymo Labels

Benefits of Dymo Labels

Some of the benefits of using Dymo labels include: * Easy to use: Dymo labels are simple to create and print, making them a great option for individuals and businesses who are new to labeling. * Versatile: Dymo labels can be used for a wide range of applications, from addressing envelopes and packages to creating signs and labels for products and packaging. * Durable: Dymo labels are made from high-quality materials that are designed to be long-lasting and resistant to fading and wear. * Customizable: Dymo labels can be customized to meet your specific needs and requirements, making them a great option for businesses and individuals who want to create professional-looking labels.Choosing the Right Dymo Label

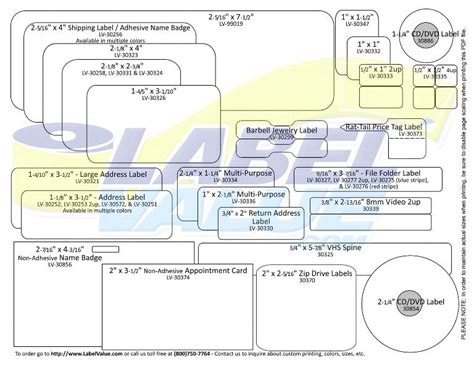

Popular Dymo Label Types

Some popular types of Dymo labels include: * Address labels: These labels are designed for addressing envelopes and packages and are available in a range of sizes and materials. * Shipping labels: These labels are designed for creating shipping labels for packages and are available in a range of sizes and materials. * File folder labels: These labels are designed for labeling file folders and are available in a range of sizes and materials. * Product labels: These labels are designed for creating labels for products and packaging and are available in a range of sizes and materials.Creating Custom Dymo Labels

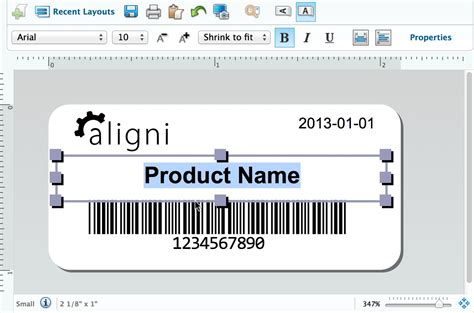

Designing Your Label

When designing your label, consider the following: * Keep it simple: Avoid cluttering your label with too much information. Keep it simple and easy to read. * Use a clear and concise font: Choose a font that is easy to read and understand, and use a clear and concise format for your label. * Use color: Consider using color to make your label stand out and to draw attention to important information.Printing Dymo Labels

Troubleshooting Common Printing Issues

Some common printing issues with Dymo labels include: * Labels not feeding properly: Make sure the labels are aligned properly and that the printer is set to the correct label size. * Labels not printing clearly: Check the ink or toner levels in your printer and make sure the labels are properly aligned. * Labels not sticking: Check the adhesive on the labels and make sure they are applied to a clean, dry surface.Maintaining Your Dymo Label Maker

Common Maintenance Tasks

Some common maintenance tasks for Dymo label makers include: * Cleaning the print head: Use a soft cloth and gentle cleaning solution to clean the print head and remove any dust or debris. * Replacing the ink or toner: Replace the ink or toner when the levels are low to ensure proper printing. * Updating the software: Check for software updates regularly to ensure you have the latest features and functionality.Dymo Label Image Gallery

What is the best way to create custom Dymo labels?

+The best way to create custom Dymo labels is to use a Dymo label maker and follow the manufacturer's instructions for designing and printing labels.

How do I troubleshoot common printing issues with Dymo labels?

+To troubleshoot common printing issues with Dymo labels, check the ink or toner levels, make sure the labels are aligned properly, and clean the printer regularly.

What are some common maintenance tasks for Dymo label makers?

+Some common maintenance tasks for Dymo label makers include cleaning the print head, replacing the ink or toner, and updating the software.

How do I choose the right Dymo label for my needs?

+To choose the right Dymo label for your needs, consider the application, the environment in which the label will be used, and the size and material of the label.

What are some benefits of using Dymo labels?

+Some benefits of using Dymo labels include ease of use, versatility, durability, and customizability.

In conclusion, Dymo labels are a versatile and convenient labeling solution that can be used for a wide range of applications. By following the tips and guidelines outlined in this article, you can get the most out of your Dymo labels and create professional-looking labels that are both durable and long-lasting. Whether you are looking to create labels for a small business or a large corporation, Dymo has everything you need to create and print your own labels. We hope this article has been helpful in providing you with the information you need to get started with Dymo labels. If you have any further questions or would like to share your own experiences with Dymo labels, please don't hesitate to comment below.