Intro

Boost labeling efficiency with 5 Dymo Label Tips, including organization, font styles, and printer maintenance, to optimize label maker usage and improve productivity with custom labels, label templates, and more.

The importance of labeling cannot be overstated, as it plays a crucial role in organization, identification, and communication in various settings, including homes, offices, and industries. Among the numerous labeling solutions available, Dymo labels have emerged as a popular choice due to their ease of use, versatility, and high-quality printing. Whether you are looking to organize your files, label cables, or create signs, Dymo labels offer a convenient and efficient way to get the job done. In this article, we will delve into the world of Dymo labels, exploring their benefits, features, and providing valuable tips on how to maximize their potential.

The use of Dymo labels can significantly enhance productivity and reduce confusion in the workplace or at home. By clearly labeling files, folders, and other items, individuals can quickly identify what they need, saving time and effort. Moreover, Dymo labels are widely used in industries such as shipping and logistics, where accurate labeling is critical for ensuring that packages are delivered to the correct destinations. With the increasing demand for efficient labeling solutions, it is essential to understand how to use Dymo labels effectively.

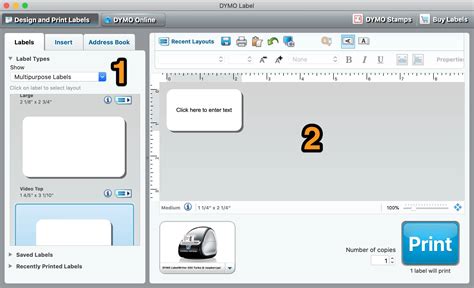

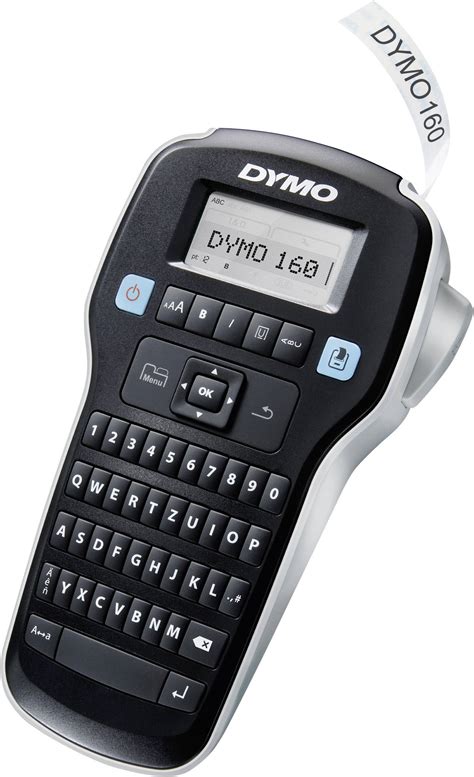

Dymo labels are designed to be user-friendly, allowing individuals to create and print labels with ease. The Dymo labeling system consists of a label maker and labels, which are available in various sizes, shapes, and materials. The label maker is equipped with a keyboard and display screen, making it simple to type and print labels. Additionally, many Dymo label makers are compatible with computers and mobile devices, enabling users to design and print labels using specialized software or apps. With the numerous benefits and features of Dymo labels, it is essential to learn how to use them efficiently.

Introduction to Dymo Labels

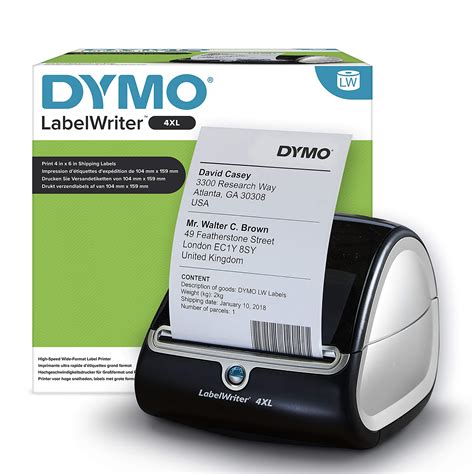

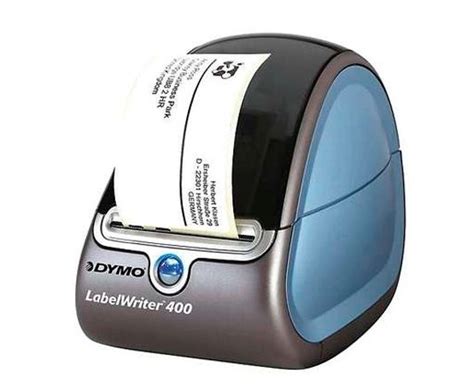

Dymo labels have been a staple in the labeling industry for decades, providing a reliable and efficient way to create and print labels. The company offers a wide range of label makers and labels, catering to various needs and applications. From basic handheld label makers to advanced desktop models, Dymo has a solution for every labeling requirement. The labels themselves are available in different sizes, shapes, and materials, including paper, plastic, and vinyl. This versatility makes Dymo labels suitable for various environments, including offices, warehouses, and homes.

Benefits of Using Dymo Labels

The benefits of using Dymo labels are numerous, making them an ideal choice for individuals and organizations. Some of the key advantages include:

- Ease of use: Dymo label makers are designed to be user-friendly, allowing individuals to create and print labels quickly and efficiently.

- Versatility: Dymo labels are available in various sizes, shapes, and materials, making them suitable for different applications and environments.

- High-quality printing: Dymo label makers produce high-quality prints, ensuring that labels are clear and legible.

- Cost-effective: Dymo labels are a cost-effective solution for labeling, as they eliminate the need for expensive printing equipment and materials.

- Durability: Dymo labels are designed to be durable, withstanding various environmental conditions, including moisture, heat, and abrasion.

Choosing the Right Dymo Label Maker

With the numerous Dymo label makers available, selecting the right one can be overwhelming. To make an informed decision, consider the following factors:

- Label size and shape: Determine the size and shape of labels you need, as different label makers support various label sizes.

- Printing resolution: Choose a label maker with a high printing resolution to ensure clear and legible labels.

- Connectivity: Consider a label maker with wireless or USB connectivity to enable printing from computers or mobile devices.

- Battery life: If you plan to use the label maker on the go, opt for a model with a long battery life or one that can be powered via USB.

- Additional features: Some Dymo label makers come with additional features, such as cutters, tape dispensers, or carrying cases.

5 Dymo Label Tips

To maximize the potential of Dymo labels, follow these valuable tips:

- Use the correct label size: Ensure you are using the correct label size for your label maker to avoid wasting labels and to achieve the best printing results.

- Choose the right label material: Select a label material that suits your application, such as paper for indoor use or vinyl for outdoor use.

- Use a consistent labeling system: Establish a consistent labeling system to ensure that labels are easy to read and understand.

- Keep your label maker clean: Regularly clean your label maker to prevent dust and debris from accumulating and affecting print quality.

- Use Dymo software: Utilize Dymo software to design and print labels from your computer or mobile device, enabling you to create complex labels with ease.

Dymo Label Applications

Dymo labels have a wide range of applications, including:

- Office organization: Use Dymo labels to organize files, folders, and documents in the office.

- Shipping and logistics: Utilize Dymo labels to create shipping labels, address labels, and package labels.

- Inventory management: Label inventory items, shelves, and storage containers to efficiently manage stock.

- Cable management: Use Dymo labels to identify cables, wires, and other IT equipment.

- Home organization: Apply Dymo labels to storage containers, shelves, and files to keep your home organized.

Dymo Label Maker Maintenance

To ensure your Dymo label maker continues to function optimally, perform regular maintenance tasks, such as:

- Cleaning the print head and cutter

- Updating the label maker's software

- Replacing the battery or power source

- Storing the label maker in a dry, cool environment

- Using genuine Dymo labels and supplies

Gallery of Dymo Labels

Dymo Label Image Gallery

What is the best way to clean a Dymo label maker?

+The best way to clean a Dymo label maker is to use a soft cloth and gentle cleaning solution to wipe down the exterior and interior of the device. Avoid using harsh chemicals or abrasive materials that may damage the label maker.

Can I use Dymo labels outdoors?

+Yes, Dymo labels can be used outdoors, but it is essential to choose a label material that is designed for outdoor use, such as vinyl or polyester. These materials are more resistant to moisture, heat, and abrasion, making them suitable for outdoor applications.

How do I troubleshoot a Dymo label maker that is not printing?

+To troubleshoot a Dymo label maker that is not printing, check the following: ensure the label maker is turned on, the labels are properly aligned, and the print head is clean. Also, verify that the label maker is loaded with the correct label size and type.

In conclusion, Dymo labels offer a convenient and efficient way to create and print labels for various applications. By following the tips and guidelines outlined in this article, individuals can maximize the potential of Dymo labels and achieve professional-looking results. Whether you are organizing your home, managing inventory, or creating shipping labels, Dymo labels are an ideal solution. We invite you to share your experiences with Dymo labels and provide feedback on this article. Your input will help us create more informative and helpful content in the future.