Intro

The art of flame cutting has been a cornerstone of metal fabrication for decades, offering a precise and efficient method to cut through metal sheets and plates. With advancements in technology, flame cutting has evolved to include various techniques and tools, making it an indispensable process in numerous industries. In this article, we will delve into the world of flame cut outs, exploring their significance, applications, and the benefits they offer.

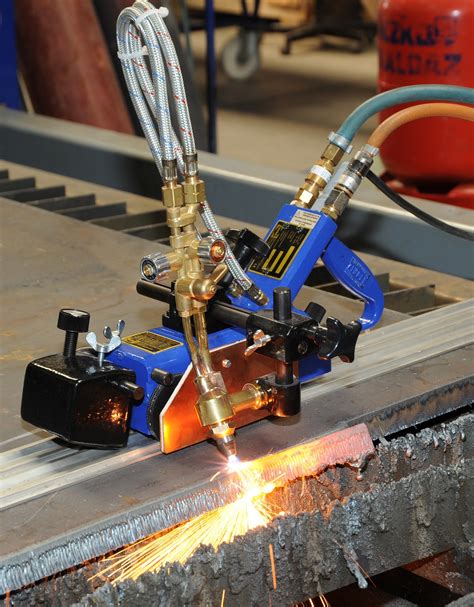

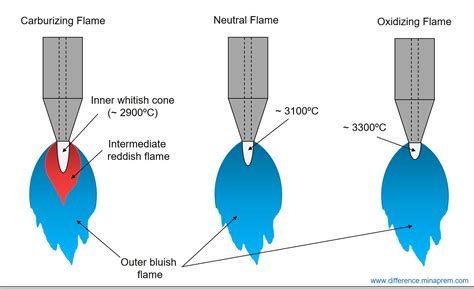

Flame cutting, also known as oxy-fuel cutting, is a process that uses a combination of oxygen and fuel gas to cut through metal. The process involves heating the metal to its ignition temperature, then introducing a stream of oxygen that burns the metal, effectively cutting it. This technique is widely used in various industries, including construction, manufacturing, and shipbuilding, due to its ability to cut through thick metal plates with precision and accuracy.

The importance of flame cut outs cannot be overstated, as they play a crucial role in the fabrication of metal components and structures. From cutting out intricate designs to creating custom shapes and sizes, flame cutting offers a level of flexibility and versatility that is hard to match with other cutting methods. Moreover, flame cut outs can be used to create complex geometries and patterns, making them an essential tool in the production of architectural features, decorative elements, and functional components.

Introduction to Flame Cut Outs

Flame cut outs are created using a flame cutting machine, which consists of a torch, a fuel gas supply, and an oxygen supply. The torch is used to heat the metal to its ignition temperature, while the fuel gas and oxygen are used to sustain the cutting process. The machine can be operated manually or automatically, depending on the complexity of the cut and the desired level of precision. With advancements in technology, computer-controlled flame cutting machines have become increasingly popular, offering improved accuracy, speed, and efficiency.

Benefits of Flame Cut Outs

The benefits of flame cut outs are numerous, making them a popular choice in various industries. Some of the key advantages include:

- High precision and accuracy, allowing for intricate cuts and complex geometries

- Ability to cut through thick metal plates, making it ideal for heavy-duty applications

- Flexibility and versatility, enabling the creation of custom shapes and sizes

- Cost-effective, compared to other cutting methods, such as laser cutting or water jet cutting

- Environmentally friendly, as it produces minimal waste and emissions

Applications of Flame Cut Outs

Flame cut outs have a wide range of applications, including:

- Construction: cutting out openings for doors, windows, and vents in metal buildings

- Manufacturing: creating custom parts and components for machinery and equipment

- Shipbuilding: cutting out hull shapes and other components for ships and boats

- Architectural features: creating decorative elements, such as balustrades and staircases

- Functional components: producing parts for machinery, such as gears, shafts, and bearings

Types of Flame Cut Outs

There are several types of flame cut outs, each with its own unique characteristics and applications. Some of the most common types include:

- Straight cuts: used for cutting out simple shapes and sizes

- Beveled cuts: used for cutting out angled or tapered shapes

- Radius cuts: used for cutting out curved or rounded shapes

- Profile cuts: used for cutting out complex geometries and patterns

Working with Flame Cut Outs

Working with flame cut outs requires a combination of skill, experience, and attention to detail. Some of the key considerations include:

- Selecting the right type of flame cutting machine and torch for the job

- Setting the correct cutting parameters, such as speed, temperature, and oxygen flow

- Using the correct type of fuel gas and oxygen supply

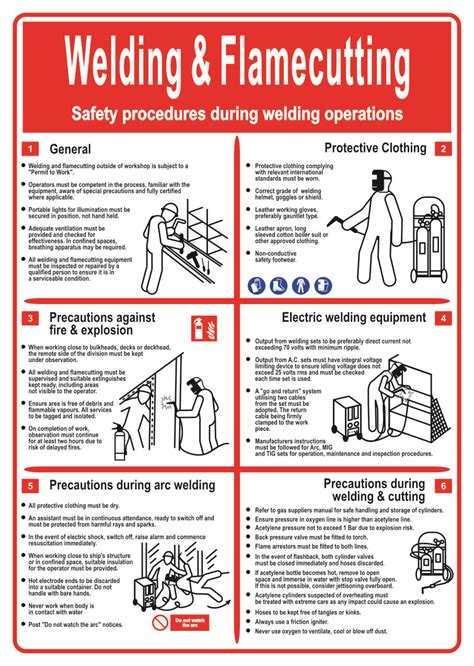

- Ensuring proper safety precautions, such as wearing protective gear and following safety protocols

Maintenance and Repair of Flame Cut Outs

Regular maintenance and repair are essential to ensure the optimal performance and longevity of flame cut outs. Some of the key maintenance tasks include:

- Cleaning and inspecting the torch and nozzle

- Replacing worn or damaged parts, such as the electrode and insulator

- Checking and adjusting the cutting parameters, such as speed and temperature

- Performing routine safety checks, such as leak testing and functional testing

Gallery of Flame Cut Outs

Flame Cut Outs Image Gallery

What is flame cutting and how does it work?

+Flame cutting, also known as oxy-fuel cutting, is a process that uses a combination of oxygen and fuel gas to cut through metal. The process involves heating the metal to its ignition temperature, then introducing a stream of oxygen that burns the metal, effectively cutting it.

What are the benefits of flame cut outs?

+The benefits of flame cut outs include high precision and accuracy, ability to cut through thick metal plates, flexibility and versatility, cost-effectiveness, and environmental friendliness.

What are the common applications of flame cut outs?

+Flame cut outs have a wide range of applications, including construction, manufacturing, shipbuilding, architectural features, and functional components.

In conclusion, flame cut outs are a vital component of metal fabrication, offering a precise and efficient method to cut through metal sheets and plates. With their numerous benefits, versatility, and wide range of applications, flame cut outs continue to play a crucial role in various industries. Whether you are a seasoned professional or an amateur, understanding the art of flame cutting and the importance of flame cut outs can help you unlock new possibilities and achieve your goals. We invite you to share your thoughts and experiences with flame cut outs, and to explore the many resources available to help you master this valuable skill.