Intro

The world of textile printing has evolved significantly over the years, and one of the most popular methods today is inkjet fabric printing. This technique allows for vibrant, high-quality prints on a wide range of fabrics, making it a favorite among fashion designers, quilters, and crafters alike. In this article, we will delve into the world of inkjet fabric printing, exploring its benefits, working mechanisms, and the various ways it can be used to create stunning textile designs.

Inkjet fabric printing is a digital printing method that uses inkjet technology to print designs directly onto fabric. This method offers a high degree of precision and flexibility, allowing for intricate designs and vibrant colors to be printed with ease. One of the key advantages of inkjet fabric printing is its ability to print small batches of fabric, making it an ideal choice for designers who want to create unique, one-of-a-kind textiles.

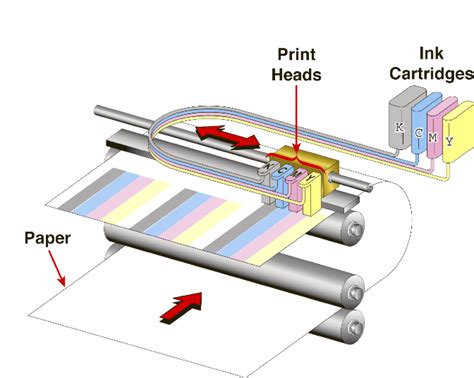

The process of inkjet fabric printing involves several key steps. First, the fabric is prepared by treating it with a special coating that allows the ink to adhere to the fabric. Next, the design is created using specialized software, and the ink is then applied to the fabric using an inkjet printer. The ink is made up of tiny droplets that are precisely controlled by the printer, allowing for highly detailed and accurate prints.

Inkjet Fabric Printing Methods

There are several ways to use inkjet fabric printing, each with its own unique benefits and applications. Here are five ways inkjet fabric printing can be used to create stunning textile designs:

1. Direct-to-Fabric Printing

Direct-to-fabric printing is a method of inkjet fabric printing that involves printing directly onto the fabric using an inkjet printer. This method allows for high-quality prints with vibrant colors and intricate details. Direct-to-fabric printing is ideal for printing small batches of fabric, making it a popular choice among fashion designers and crafters.2. Sublimation Printing

Sublimation printing is a method of inkjet fabric printing that involves printing onto a special transfer paper using sublimation ink. The transfer paper is then applied to the fabric, and the design is transferred onto the fabric using heat and pressure. Sublimation printing is ideal for printing onto synthetic fabrics such as polyester and nylon.3. Pigment Printing

Pigment printing is a method of inkjet fabric printing that involves printing onto the fabric using pigment-based ink. This method allows for high-quality prints with vibrant colors and a soft, textured finish. Pigment printing is ideal for printing onto natural fibers such as cotton and linen.4. Dye-Sublimation Printing

Dye-sublimation printing is a method of inkjet fabric printing that involves printing onto a special transfer paper using dye-sublimation ink. The transfer paper is then applied to the fabric, and the design is transferred onto the fabric using heat and pressure. Dye-sublimation printing is ideal for printing onto synthetic fabrics such as polyester and nylon.5. Reactive Printing

Reactive printing is a method of inkjet fabric printing that involves printing onto the fabric using reactive ink. This method allows for high-quality prints with vibrant colors and a soft, textured finish. Reactive printing is ideal for printing onto natural fibers such as cotton and linen.Benefits of Inkjet Fabric Printing

Inkjet fabric printing offers a wide range of benefits, including:

- High-quality prints with vibrant colors and intricate details

- Ability to print small batches of fabric, making it ideal for designers who want to create unique, one-of-a-kind textiles

- Flexibility to print on a wide range of fabrics, including natural and synthetic fibers

- Environmentally friendly, as it uses minimal water and ink

- Cost-effective, as it eliminates the need for screens and other equipment required for traditional printing methods

Working Mechanisms of Inkjet Fabric Printing

The working mechanisms of inkjet fabric printing involve several key steps, including:

- Pre-treating the fabric with a special coating that allows the ink to adhere to the fabric

- Creating the design using specialized software

- Applying the ink to the fabric using an inkjet printer

- Allowing the ink to dry and cure, either through air drying or heat fixation

Steps Involved in Inkjet Fabric Printing

The steps involved in inkjet fabric printing include:

- Pre-treating the fabric with a special coating that allows the ink to adhere to the fabric

- Creating the design using specialized software

- Applying the ink to the fabric using an inkjet printer

- Allowing the ink to dry and cure, either through air drying or heat fixation

- Washing and drying the fabric to remove any excess ink and fix the design

Practical Examples of Inkjet Fabric Printing

Inkjet fabric printing has a wide range of practical applications, including:

- Fashion design: Inkjet fabric printing is used to create unique, one-of-a-kind textiles for fashion designers and brands.

- Quilting: Inkjet fabric printing is used to create custom quilting fabrics with intricate designs and vibrant colors.

- Crafting: Inkjet fabric printing is used to create custom fabrics for crafters and DIY enthusiasts.

Statistical Data on Inkjet Fabric Printing

According to recent statistics, the inkjet fabric printing market is expected to grow significantly in the next few years, driven by increasing demand for digital printing technologies and the growing popularity of sustainable and environmentally friendly printing methods.

Gallery of Inkjet Fabric Printing

Inkjet Fabric Printing Image Gallery

What is inkjet fabric printing?

+Inkjet fabric printing is a digital printing method that uses inkjet technology to print designs directly onto fabric.

What are the benefits of inkjet fabric printing?

+The benefits of inkjet fabric printing include high-quality prints with vibrant colors and intricate details, ability to print small batches of fabric, flexibility to print on a wide range of fabrics, environmentally friendly, and cost-effective.

What are the different methods of inkjet fabric printing?

+The different methods of inkjet fabric printing include direct-to-fabric printing, sublimation printing, pigment printing, dye-sublimation printing, and reactive printing.

What are the practical applications of inkjet fabric printing?

+The practical applications of inkjet fabric printing include fashion design, quilting, crafting, and textile design.

How does inkjet fabric printing work?

+Inkjet fabric printing works by pre-treating the fabric with a special coating, creating the design using specialized software, applying the ink to the fabric using an inkjet printer, and allowing the ink to dry and cure.

In conclusion, inkjet fabric printing is a versatile and efficient method of printing designs onto fabric. With its high-quality prints, flexibility, and environmentally friendly nature, it has become a popular choice among fashion designers, quilters, and crafters. Whether you are looking to create unique textiles for fashion design, custom quilting fabrics, or simply want to explore the world of digital printing, inkjet fabric printing is definitely worth considering. We hope this article has provided you with a comprehensive understanding of inkjet fabric printing and its many benefits. If you have any questions or comments, please feel free to share them with us. We would love to hear from you and help you get started with your inkjet fabric printing journey.