Intro

Discover 5 ways to work with heat transfer vinyl, including cutting, weeding, and applying techniques for custom designs, vinyl crafts, and heat press projects.

Heat transfer vinyl, also known as HTV, has become a popular material in the world of crafting and DIY projects. It's a type of vinyl that can be cut into various shapes and designs, and then applied to different surfaces using heat and pressure. The result is a durable, long-lasting, and professional-looking finish that can be used for a wide range of applications. In this article, we will explore five ways to use heat transfer vinyl, including its benefits, working mechanisms, and practical examples.

Heat transfer vinyl is a versatile material that can be used for various projects, from custom t-shirts and hoodies to phone cases and laptop skins. One of the main advantages of HTV is its ease of use. With a heat press or a household iron, you can apply the vinyl to your desired surface in just a few minutes. Additionally, HTV is available in a wide range of colors, patterns, and finishes, making it easy to find the perfect match for your project.

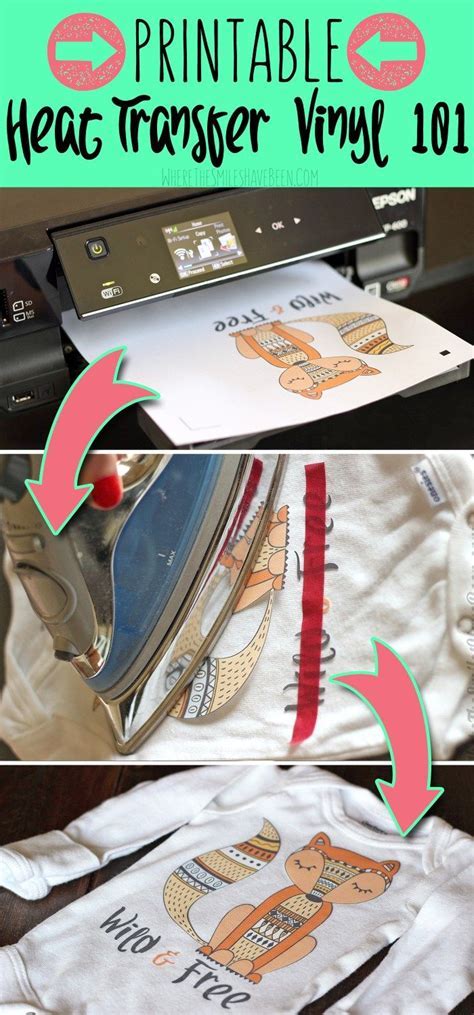

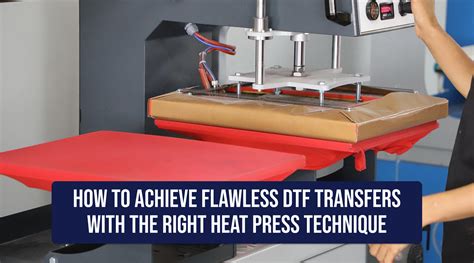

The working mechanism of heat transfer vinyl is relatively simple. The vinyl is cut into the desired shape or design using a cutting machine or a craft knife. The cut vinyl is then placed on the surface, and heat and pressure are applied using a heat press or an iron. The heat causes the vinyl to melt and bond with the surface, creating a strong and durable finish. The pressure ensures that the vinyl is applied evenly and smoothly, preventing wrinkles and air bubbles.

Introduction to Heat Transfer Vinyl

Heat transfer vinyl is a type of vinyl that is specifically designed for heat transfer applications. It's made from a thin, flexible material that can be cut into various shapes and designs. The vinyl is coated with a heat-activated adhesive that melts when exposed to heat, allowing it to bond with the surface. HTV is available in a wide range of colors, patterns, and finishes, making it easy to find the perfect match for your project.

Benefits of Heat Transfer Vinyl

One of the main benefits of heat transfer vinyl is its ease of use. With a heat press or a household iron, you can apply the vinyl to your desired surface in just a few minutes. Additionally, HTV is a cost-effective material that can be used for a wide range of applications, from custom apparel to signage and decals. The vinyl is also durable and long-lasting, making it perfect for projects that need to withstand heavy use or harsh environments.

Types of Heat Transfer Vinyl

There are several types of heat transfer vinyl available, each with its own unique characteristics and benefits. Some of the most common types of HTV include: * Glossy vinyl: This type of vinyl has a shiny, reflective finish that's perfect for projects that need to stand out. * Matte vinyl: This type of vinyl has a flat, non-reflective finish that's perfect for projects that need a subtle look. * Metallic vinyl: This type of vinyl has a metallic finish that's perfect for projects that need a touch of luxury and sophistication. * Glitter vinyl: This type of vinyl has a glittery finish that's perfect for projects that need a touch of fun and sparkle.Applications of Heat Transfer Vinyl

Heat transfer vinyl can be used for a wide range of applications, from custom apparel to signage and decals. Some of the most common applications of HTV include:

- Custom t-shirts and hoodies: HTV is perfect for creating custom designs and logos on t-shirts and hoodies.

- Phone cases and laptop skins: HTV can be used to create custom designs and patterns on phone cases and laptop skins.

- Signage and decals: HTV can be used to create custom signage and decals for businesses and organizations.

- Craft projects: HTV can be used for a wide range of craft projects, from custom jewelry to home decor.

Tips and Tricks for Working with Heat Transfer Vinyl

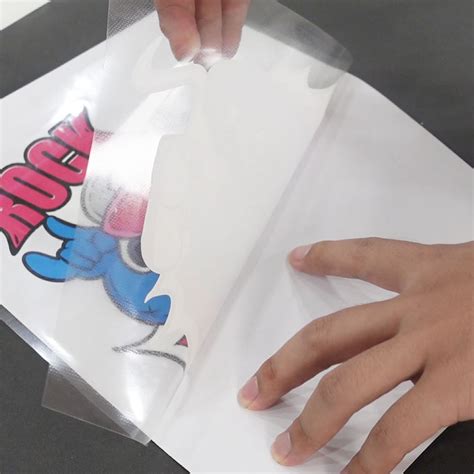

Here are some tips and tricks for working with heat transfer vinyl: * Use a heat press: A heat press is the best way to apply heat transfer vinyl, as it provides even heat and pressure. * Use a cutting machine: A cutting machine is the best way to cut heat transfer vinyl, as it provides precise cuts and minimizes waste. * Use a weeding tool: A weeding tool is used to remove excess vinyl from the design, making it easier to apply. * Use a transfer tape: A transfer tape is used to transfer the vinyl design to the surface, making it easier to apply.Common Mistakes to Avoid When Working with Heat Transfer Vinyl

Here are some common mistakes to avoid when working with heat transfer vinyl:

- Not using enough heat: Not using enough heat can result in the vinyl not bonding properly with the surface.

- Not using enough pressure: Not using enough pressure can result in the vinyl not being applied evenly.

- Not weeding the vinyl: Not weeding the vinyl can result in excess vinyl being applied to the surface.

- Not using a transfer tape: Not using a transfer tape can result in the vinyl design being applied unevenly.

Conclusion and Future of Heat Transfer Vinyl

In conclusion, heat transfer vinyl is a versatile material that can be used for a wide range of applications. With its ease of use, cost-effectiveness, and durability, HTV is perfect for projects that need a professional-looking finish. As technology continues to advance, we can expect to see new and innovative uses for heat transfer vinyl.Heat Transfer Vinyl Image Gallery

What is heat transfer vinyl?

+Heat transfer vinyl is a type of vinyl that is specifically designed for heat transfer applications. It's made from a thin, flexible material that can be cut into various shapes and designs.

How do I apply heat transfer vinyl?

+Heat transfer vinyl can be applied using a heat press or a household iron. The vinyl is cut into the desired shape or design, and then placed on the surface. Heat and pressure are applied, causing the vinyl to melt and bond with the surface.

What are the benefits of heat transfer vinyl?

+The benefits of heat transfer vinyl include its ease of use, cost-effectiveness, and durability. It's a versatile material that can be used for a wide range of applications, from custom apparel to signage and decals.

Can I use heat transfer vinyl on any surface?

+No, heat transfer vinyl is not suitable for all surfaces. It's best used on surfaces that can withstand heat and pressure, such as cotton, polyester, and nylon. It's not recommended for use on surfaces that are sensitive to heat or pressure, such as silk or wool.

How long does heat transfer vinyl last?

+The lifespan of heat transfer vinyl depends on the quality of the vinyl and the surface it's applied to. On average, heat transfer vinyl can last for several years, even with heavy use. However, it's not permanent and may need to be replaced over time.

We hope this article has provided you with a comprehensive overview of heat transfer vinyl and its many uses. Whether you're a seasoned crafter or just starting out, HTV is a versatile material that can help you create professional-looking projects with ease. If you have any questions or comments, please don't hesitate to reach out. We'd love to hear from you and help you get started with your next heat transfer vinyl project.