Intro

Optimize inventory management with effective control strategies, leveraging techniques like just-in-time, ABC analysis, and periodic review to minimize stockouts and overstocking, improving supply chain efficiency and reducing costs.

Effective inventory control is crucial for businesses to minimize costs, maximize efficiency, and ensure customer satisfaction. Inventory control strategies are designed to manage the flow of goods, products, or materials from procurement to delivery, ensuring that the right products are available at the right time and in the right quantities. In today's fast-paced business environment, companies must adopt efficient inventory control strategies to stay competitive and profitable.

Inventory control is a critical aspect of supply chain management, as it directly affects a company's bottom line. Excess inventory can lead to unnecessary storage costs, obsolescence, and waste, while stockouts can result in lost sales, damaged customer relationships, and reputational harm. Therefore, businesses must implement effective inventory control strategies to balance supply and demand, reduce costs, and improve customer satisfaction.

The importance of inventory control cannot be overstated, as it has a significant impact on a company's financial performance, operational efficiency, and customer satisfaction. By implementing effective inventory control strategies, businesses can reduce inventory costs, improve cash flow, and enhance their competitive advantage. In this article, we will explore the different inventory control strategies, their benefits, and best practices for implementation.

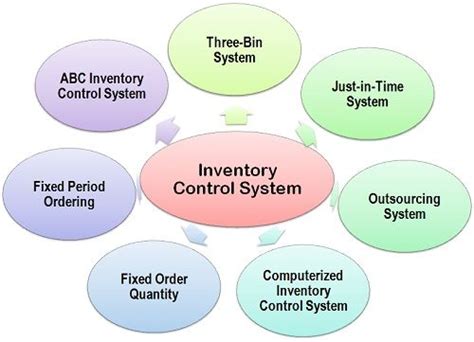

Types of Inventory Control Strategies

There are several types of inventory control strategies that businesses can adopt, depending on their specific needs and goals. These strategies include:

- Just-in-Time (JIT) inventory management: This strategy involves ordering and receiving inventory just in time to meet customer demand, reducing inventory holding costs and minimizing waste.

- Economic Order Quantity (EOQ) model: This strategy involves calculating the optimal order quantity to minimize total inventory costs, including ordering costs, holding costs, and stockout costs.

- Vendor-Managed Inventory (VMI) system: This strategy involves partnering with suppliers to manage inventory levels, reducing the need for inventory holding and minimizing stockouts.

- Drop shipping: This strategy involves shipping products directly from the supplier to the customer, eliminating the need for inventory holding and reducing shipping costs.

Benefits of Inventory Control Strategies

The benefits of inventory control strategies are numerous and significant. By implementing effective inventory control strategies, businesses can:- Reduce inventory costs: By minimizing inventory holding costs, reducing waste, and optimizing order quantities, businesses can significantly reduce their inventory costs.

- Improve cash flow: By reducing inventory levels and minimizing inventory holding costs, businesses can free up cash for other uses, such as investing in new products or expanding their operations.

- Enhance customer satisfaction: By ensuring that products are available when customers need them, businesses can improve customer satisfaction and loyalty.

- Improve operational efficiency: By streamlining inventory management processes and reducing inventory levels, businesses can improve their operational efficiency and reduce waste.

Inventory Control Best Practices

To implement effective inventory control strategies, businesses should follow best practices, including:

- Conducting regular inventory audits: Regular inventory audits help businesses to identify discrepancies, reduce errors, and optimize inventory levels.

- Implementing inventory management software: Inventory management software helps businesses to track inventory levels, automate ordering processes, and optimize inventory management.

- Analyzing inventory data: Analyzing inventory data helps businesses to identify trends, optimize inventory levels, and improve forecasting accuracy.

- Implementing a first-in, first-out (FIFO) inventory system: A FIFO inventory system helps businesses to reduce waste, minimize obsolescence, and improve inventory turnover.

Common Inventory Control Challenges

Despite the benefits of inventory control strategies, businesses often face challenges in implementing and maintaining effective inventory control systems. Common challenges include:- Inaccurate forecasting: Inaccurate forecasting can lead to overstocking or understocking, resulting in wasted resources and lost sales.

- Insufficient inventory management software: Insufficient inventory management software can make it difficult to track inventory levels, automate ordering processes, and optimize inventory management.

- Lack of training: Lack of training can lead to errors, inaccuracies, and inefficiencies in inventory management processes.

- Inadequate inventory storage facilities: Inadequate inventory storage facilities can lead to damage, loss, and waste of inventory.

Inventory Control Technologies

Inventory control technologies have revolutionized the way businesses manage their inventory. Some of the most common inventory control technologies include:

- Barcode scanning: Barcode scanning helps businesses to track inventory levels, automate ordering processes, and optimize inventory management.

- Radio Frequency Identification (RFID) technology: RFID technology helps businesses to track inventory levels, automate ordering processes, and optimize inventory management.

- Inventory management software: Inventory management software helps businesses to track inventory levels, automate ordering processes, and optimize inventory management.

- Cloud-based inventory management systems: Cloud-based inventory management systems help businesses to track inventory levels, automate ordering processes, and optimize inventory management from anywhere, at any time.

Future of Inventory Control

The future of inventory control is exciting and rapidly evolving. With the advent of new technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT), businesses can expect to see significant improvements in inventory control efficiency, accuracy, and effectiveness. Some of the trends that are expected to shape the future of inventory control include:- Increased use of automation: Automation is expected to play a major role in inventory control, with businesses using robots, drones, and other automated systems to manage inventory.

- Greater use of data analytics: Data analytics is expected to play a major role in inventory control, with businesses using data to optimize inventory levels, predict demand, and improve forecasting accuracy.

- More emphasis on sustainability: Sustainability is expected to become a major focus of inventory control, with businesses looking for ways to reduce waste, minimize environmental impact, and improve social responsibility.

Gallery of Inventory Control Strategies

Inventory Control Strategies Image Gallery

Frequently Asked Questions

What is inventory control?

+Inventory control refers to the processes and systems used to manage and regulate the flow of goods, products, or materials from procurement to delivery.

Why is inventory control important?

+Inventory control is important because it helps businesses to minimize costs, maximize efficiency, and ensure customer satisfaction by ensuring that the right products are available at the right time and in the right quantities.

What are the benefits of inventory control strategies?

+The benefits of inventory control strategies include reduced inventory costs, improved cash flow, enhanced customer satisfaction, and improved operational efficiency.

What are some common inventory control challenges?

+Common inventory control challenges include inaccurate forecasting, insufficient inventory management software, lack of training, and inadequate inventory storage facilities.

What is the future of inventory control?

+The future of inventory control is expected to be shaped by new technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT), which will enable businesses to optimize inventory levels, predict demand, and improve forecasting accuracy.

In conclusion, inventory control strategies are crucial for businesses to minimize costs, maximize efficiency, and ensure customer satisfaction. By implementing effective inventory control strategies, businesses can reduce inventory costs, improve cash flow, and enhance their competitive advantage. As the business environment continues to evolve, it is essential for companies to stay up-to-date with the latest inventory control technologies and best practices to remain competitive and profitable. We encourage readers to share their thoughts and experiences on inventory control strategies and how they have impacted their businesses.