Intro

Discover 5 ways to calculate inventory days, optimizing stock management with turnover ratio, average days to sell, and inventory valuation for efficient supply chain management and reduced inventory costs.

Calculating inventory days is a crucial aspect of managing a business's inventory levels, as it helps to determine the average number of days that inventory remains in stock before being sold. This metric is essential for businesses to ensure they have sufficient inventory to meet customer demand, avoid stockouts, and minimize waste. In this article, we will explore five ways to calculate inventory days, providing businesses with a comprehensive understanding of their inventory management.

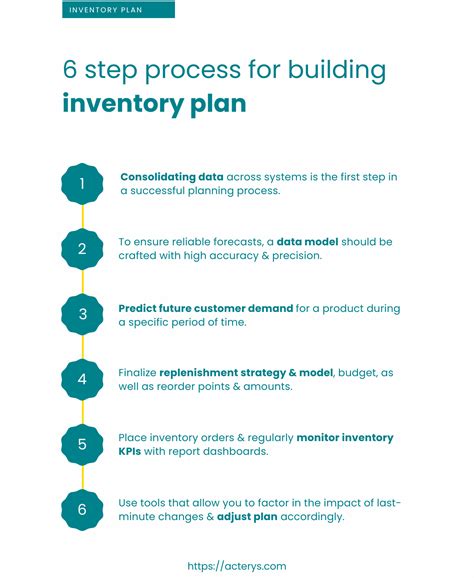

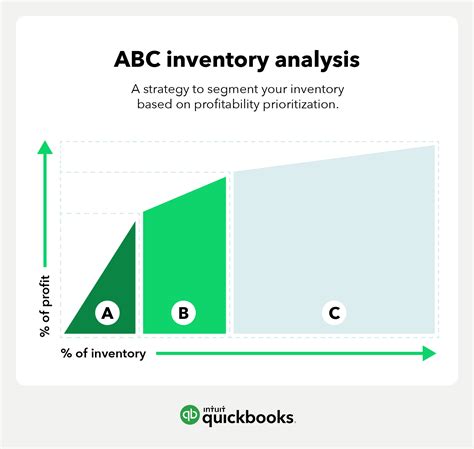

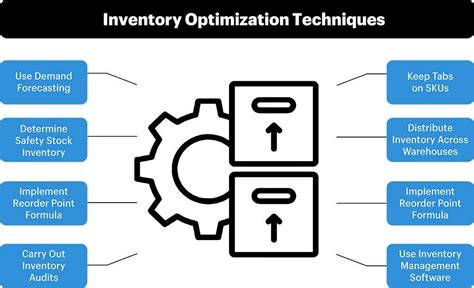

The importance of calculating inventory days cannot be overstated. By doing so, businesses can identify areas for improvement, optimize their inventory levels, and ultimately, improve their bottom line. Inventory days can help businesses to identify slow-moving items, reduce inventory holding costs, and improve their cash flow. Moreover, calculating inventory days can help businesses to make informed decisions about their inventory management, such as determining the optimal inventory levels, identifying the most profitable products, and streamlining their supply chain.

Calculating inventory days is a relatively simple process that involves dividing the average inventory level by the cost of goods sold and then multiplying by the number of days in the period. However, there are different methods to calculate inventory days, each with its own advantages and disadvantages. In the following sections, we will explore five ways to calculate inventory days, including the average inventory method, the periodic inventory method, the perpetual inventory method, the weighted average method, and the first-in, first-out (FIFO) method.

Understanding Inventory Days

Inventory days, also known as days inventory outstanding (DIO), is a metric that measures the average number of days that inventory remains in stock before being sold. This metric is essential for businesses to ensure they have sufficient inventory to meet customer demand, avoid stockouts, and minimize waste. Inventory days can be calculated using different methods, each with its own advantages and disadvantages. In the following sections, we will explore five ways to calculate inventory days, providing businesses with a comprehensive understanding of their inventory management.

Benefits of Calculating Inventory Days

Calculating inventory days can help businesses to identify areas for improvement, optimize their inventory levels, and ultimately, improve their bottom line. Some of the benefits of calculating inventory days include: * Identifying slow-moving items and reducing inventory holding costs * Improving cash flow by minimizing inventory levels * Making informed decisions about inventory management, such as determining the optimal inventory levels and identifying the most profitable products * Streamlining the supply chain and improving relationships with suppliers * Enhancing customer satisfaction by ensuring sufficient inventory to meet demandMethod 1: Average Inventory Method

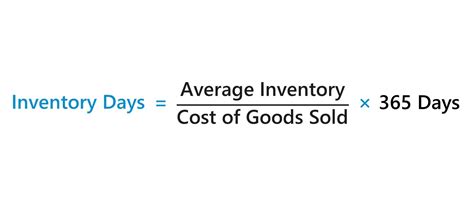

The average inventory method is a simple and widely used method to calculate inventory days. This method involves dividing the average inventory level by the cost of goods sold and then multiplying by the number of days in the period. The formula for calculating inventory days using the average inventory method is:

Inventory Days = (Average Inventory / Cost of Goods Sold) x Number of Days

For example, if the average inventory level is $100,000, the cost of goods sold is $500,000, and the number of days in the period is 365, the inventory days would be:

Inventory Days = ($100,000 / $500,000) x 365 = 73 days

Advantages and Disadvantages of the Average Inventory Method

The average inventory method is a simple and easy-to-use method to calculate inventory days. However, it has some limitations, such as: * It assumes that the inventory level remains constant throughout the period * It does not take into account the seasonal fluctuations in demand * It may not be accurate for businesses with high inventory turnover ratesMethod 2: Periodic Inventory Method

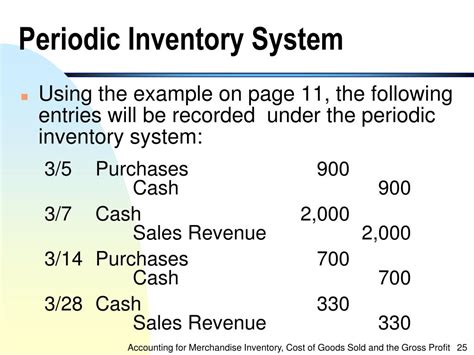

The periodic inventory method is another method to calculate inventory days. This method involves counting the inventory level at the beginning and end of the period and then calculating the average inventory level. The formula for calculating inventory days using the periodic inventory method is:

Inventory Days = (Beginning Inventory + Ending Inventory) / 2 / Cost of Goods Sold x Number of Days

For example, if the beginning inventory is $50,000, the ending inventory is $150,000, the cost of goods sold is $500,000, and the number of days in the period is 365, the inventory days would be:

Inventory Days = ($50,000 + $150,000) / 2 / $500,000 x 365 = 91 days

Advantages and Disadvantages of the Periodic Inventory Method

The periodic inventory method is a more accurate method to calculate inventory days, especially for businesses with seasonal fluctuations in demand. However, it has some limitations, such as: * It requires physical counting of inventory, which can be time-consuming and expensive * It may not be accurate for businesses with high inventory turnover ratesMethod 3: Perpetual Inventory Method

The perpetual inventory method is a method that involves continuously updating the inventory level in real-time. This method is more accurate than the average inventory method and the periodic inventory method, especially for businesses with high inventory turnover rates. The formula for calculating inventory days using the perpetual inventory method is:

Inventory Days = (Current Inventory / Cost of Goods Sold) x Number of Days

For example, if the current inventory is $100,000, the cost of goods sold is $500,000, and the number of days in the period is 365, the inventory days would be:

Inventory Days = ($100,000 / $500,000) x 365 = 73 days

Advantages and Disadvantages of the Perpetual Inventory Method

The perpetual inventory method is a more accurate method to calculate inventory days, especially for businesses with high inventory turnover rates. However, it has some limitations, such as: * It requires a sophisticated inventory management system * It may be expensive to implement and maintainMethod 4: Weighted Average Method

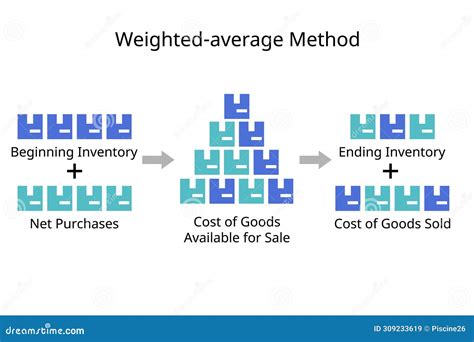

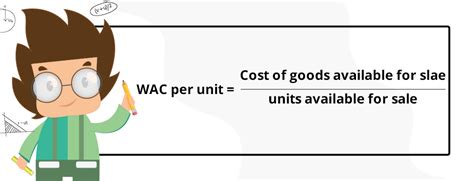

The weighted average method is a method that involves calculating the weighted average of the inventory level based on the cost of goods sold. This method is more accurate than the average inventory method and the periodic inventory method, especially for businesses with seasonal fluctuations in demand. The formula for calculating inventory days using the weighted average method is:

Inventory Days = (Weighted Average Inventory / Cost of Goods Sold) x Number of Days

For example, if the weighted average inventory is $120,000, the cost of goods sold is $500,000, and the number of days in the period is 365, the inventory days would be:

Inventory Days = ($120,000 / $500,000) x 365 = 87 days

Advantages and Disadvantages of the Weighted Average Method

The weighted average method is a more accurate method to calculate inventory days, especially for businesses with seasonal fluctuations in demand. However, it has some limitations, such as: * It requires a sophisticated inventory management system * It may be expensive to implement and maintainMethod 5: First-In, First-Out (FIFO) Method

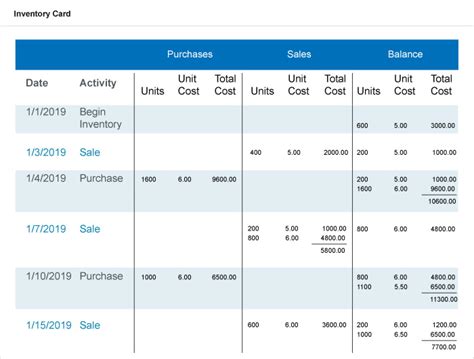

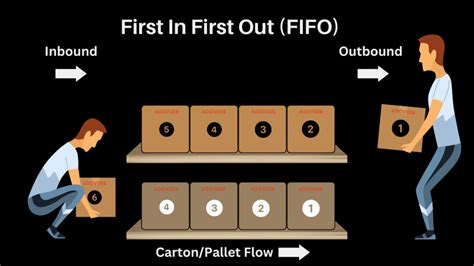

The FIFO method is a method that involves assuming that the oldest inventory is sold first. This method is more accurate than the average inventory method and the periodic inventory method, especially for businesses with high inventory turnover rates. The formula for calculating inventory days using the FIFO method is:

Inventory Days = (Current Inventory / Cost of Goods Sold) x Number of Days

For example, if the current inventory is $100,000, the cost of goods sold is $500,000, and the number of days in the period is 365, the inventory days would be:

Inventory Days = ($100,000 / $500,000) x 365 = 73 days

Advantages and Disadvantages of the FIFO Method

The FIFO method is a more accurate method to calculate inventory days, especially for businesses with high inventory turnover rates. However, it has some limitations, such as: * It assumes that the oldest inventory is sold first, which may not always be the case * It may not be accurate for businesses with seasonal fluctuations in demandGallery of Inventory Management

Inventory Management Image Gallery

Frequently Asked Questions

What is inventory days?

+Inventory days, also known as days inventory outstanding (DIO), is a metric that measures the average number of days that inventory remains in stock before being sold.

Why is calculating inventory days important?

+Calculating inventory days is important because it helps businesses to identify areas for improvement, optimize their inventory levels, and ultimately, improve their bottom line.

What are the different methods to calculate inventory days?

+The different methods to calculate inventory days include the average inventory method, the periodic inventory method, the perpetual inventory method, the weighted average method, and the first-in, first-out (FIFO) method.

What is the formula for calculating inventory days using the average inventory method?

+The formula for calculating inventory days using the average inventory method is: Inventory Days = (Average Inventory / Cost of Goods Sold) x Number of Days.

What is the advantage of using the perpetual inventory method?

+The advantage of using the perpetual inventory method is that it provides a more accurate calculation of inventory days, especially for businesses with high inventory turnover rates.

In conclusion, calculating inventory days is a crucial aspect of managing a business's inventory levels. By using one of the five methods outlined in this article, businesses can gain a better understanding of their inventory management and make informed decisions to optimize their inventory levels. Whether you are a small business owner or a large corporation, calculating inventory days can help you to improve your bottom line and stay competitive in the market. We encourage you to share your thoughts and experiences with calculating inventory days in the comments section below. Additionally, if you found this article helpful, please share it with your friends and colleagues who may benefit from learning more about inventory management.