Intro

Learn the Inventory Days Equation to optimize stock levels, reduce waste, and improve supply chain efficiency with key metrics like inventory turnover, average inventory, and cost of goods sold.

The inventory days equation, also known as the days inventory outstanding (DIO) or days inventory held, is a crucial metric used to evaluate a company's inventory management efficiency. It measures the average number of days that a company holds its inventory before selling it. In today's fast-paced business environment, understanding the inventory days equation is vital for companies to optimize their inventory levels, reduce costs, and improve cash flow. In this article, we will delve into the importance of the inventory days equation, its calculation, and its implications for businesses.

Effective inventory management is essential for companies to maintain a competitive edge in the market. Excess inventory can lead to unnecessary costs, such as storage and maintenance expenses, while stockouts can result in lost sales and damaged customer relationships. The inventory days equation helps companies strike a balance between inventory levels and demand, ensuring that they have sufficient stock to meet customer needs without overstocking. By analyzing the inventory days equation, companies can identify areas for improvement, streamline their supply chain, and make informed decisions about inventory investments.

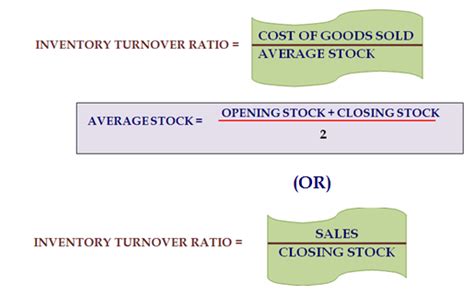

The inventory days equation is a straightforward calculation that involves dividing the average inventory by the cost of goods sold per day. The formula is: Inventory Days = (Average Inventory / Cost of Goods Sold) x 365. Where average inventory is the average value of inventory held during a specific period, and cost of goods sold is the total cost of producing or purchasing the goods sold during that period. The result is the average number of days that inventory remains in stock before being sold. This metric provides valuable insights into a company's inventory turnover, helping managers to assess the efficiency of their inventory management strategies.

Understanding the Inventory Days Equation

To grasp the inventory days equation, it is essential to understand its components and how they interact. The average inventory is a critical component, as it reflects the inventory levels throughout a specific period. The cost of goods sold, on the other hand, represents the direct costs associated with producing or purchasing the goods sold. By dividing the average inventory by the cost of goods sold per day, companies can determine the average number of days that inventory remains in stock. This metric is vital for businesses, as it helps them to identify trends, optimize inventory levels, and improve their overall inventory management.

Calculating the Inventory Days Equation

The calculation of the inventory days equation involves several steps. First, companies need to determine their average inventory, which can be calculated by adding the beginning and ending inventory and dividing by two. Next, they need to calculate the cost of goods sold per day, which can be done by dividing the total cost of goods sold by 365. Finally, companies can plug these values into the inventory days equation formula to obtain the average number of days that inventory remains in stock. By following these steps, businesses can gain valuable insights into their inventory management efficiency and make informed decisions about their inventory investments.Interpreting the Inventory Days Equation Results

The results of the inventory days equation provide valuable insights into a company's inventory management efficiency. A lower inventory days value indicates that a company is selling its inventory quickly, which can be beneficial for cash flow and reducing inventory holding costs. On the other hand, a higher inventory days value may indicate that a company is holding excess inventory, which can lead to unnecessary costs and inefficiencies. By analyzing the inventory days equation results, companies can identify areas for improvement, optimize their inventory levels, and develop strategies to reduce inventory holding costs.

Implications of the Inventory Days Equation

The inventory days equation has significant implications for businesses, as it helps them to evaluate their inventory management efficiency and make informed decisions about their inventory investments. By analyzing the inventory days equation results, companies can identify trends, optimize inventory levels, and improve their overall inventory management. Additionally, the inventory days equation can help companies to reduce inventory holding costs, improve cash flow, and enhance their competitiveness in the market. By understanding the inventory days equation and its implications, businesses can develop effective inventory management strategies that drive growth, profitability, and success.Best Practices for Inventory Management

Effective inventory management is crucial for businesses to maintain a competitive edge in the market. To optimize inventory levels and reduce costs, companies should adopt best practices such as demand forecasting, inventory classification, and supply chain optimization. Demand forecasting involves analyzing historical sales data and market trends to predict future demand. Inventory classification involves categorizing inventory into different classes based on their value, velocity, and criticality. Supply chain optimization involves streamlining the supply chain to reduce lead times, improve quality, and lower costs. By adopting these best practices, companies can improve their inventory management efficiency, reduce costs, and enhance their competitiveness in the market.

Common Challenges in Inventory Management

Despite the importance of inventory management, many companies face challenges in optimizing their inventory levels and reducing costs. Common challenges include inaccurate demand forecasting, inadequate inventory classification, and inefficient supply chain management. Inaccurate demand forecasting can lead to overstocking or understocking, while inadequate inventory classification can result in inefficient inventory allocation. Inefficient supply chain management can lead to delays, quality issues, and increased costs. By understanding these challenges and adopting best practices, companies can overcome them and develop effective inventory management strategies that drive growth, profitability, and success.Technologies for Inventory Management

The inventory management landscape is evolving rapidly, with the advent of new technologies that enable companies to optimize their inventory levels and reduce costs. Some of the key technologies include inventory management software, radio-frequency identification (RFID) systems, and cloud-based inventory management platforms. Inventory management software provides real-time visibility into inventory levels, enables automated reporting, and streamlines inventory tracking. RFID systems enable companies to track inventory movements, reduce errors, and improve inventory accuracy. Cloud-based inventory management platforms provide scalability, flexibility, and collaboration, enabling companies to manage their inventory across multiple locations and channels. By leveraging these technologies, companies can improve their inventory management efficiency, reduce costs, and enhance their competitiveness in the market.

Future of Inventory Management

The future of inventory management is exciting, with the emergence of new technologies and trends that will shape the industry. Some of the key trends include the use of artificial intelligence (AI) and machine learning (ML) in inventory management, the adoption of blockchain technology, and the rise of omnichannel inventory management. AI and ML can help companies to predict demand, optimize inventory levels, and improve inventory allocation. Blockchain technology can enable companies to track inventory movements, reduce counterfeiting, and improve supply chain transparency. Omnichannel inventory management involves managing inventory across multiple channels, including online, offline, and mobile. By embracing these trends and technologies, companies can develop effective inventory management strategies that drive growth, profitability, and success.Gallery of Inventory Management

Inventory Management Image Gallery

Frequently Asked Questions

What is the inventory days equation?

+The inventory days equation is a metric used to evaluate a company's inventory management efficiency. It measures the average number of days that a company holds its inventory before selling it.

How is the inventory days equation calculated?

+The inventory days equation is calculated by dividing the average inventory by the cost of goods sold per day. The formula is: Inventory Days = (Average Inventory / Cost of Goods Sold) x 365.

What are the implications of the inventory days equation?

+The inventory days equation has significant implications for businesses, as it helps them to evaluate their inventory management efficiency and make informed decisions about their inventory investments. By analyzing the inventory days equation results, companies can identify trends, optimize inventory levels, and improve their overall inventory management.

What are some best practices for inventory management?

+Some best practices for inventory management include demand forecasting, inventory classification, and supply chain optimization. By adopting these best practices, companies can improve their inventory management efficiency, reduce costs, and enhance their competitiveness in the market.

What is the future of inventory management?

+The future of inventory management is exciting, with the emergence of new technologies and trends that will shape the industry. Some of the key trends include the use of artificial intelligence (AI) and machine learning (ML) in inventory management, the adoption of blockchain technology, and the rise of omnichannel inventory management.

In conclusion, the inventory days equation is a vital metric that helps companies to evaluate their inventory management efficiency and make informed decisions about their inventory investments. By understanding the inventory days equation, its calculation, and its implications, businesses can develop effective inventory management strategies that drive growth, profitability, and success. We hope that this article has provided you with valuable insights into the inventory days equation and its importance in inventory management. If you have any questions or comments, please do not hesitate to reach out to us. Share this article with your friends and colleagues to help them understand the importance of inventory management in business.