Intro

Calculate inventory turnover with the inventory days formula, a key metric for stock management, optimizing supply chain efficiency, and reducing inventory holding costs, to improve cash flow and business performance.

The importance of understanding inventory management cannot be overstated, as it plays a critical role in the success of any business. One key aspect of inventory management is the concept of inventory days, which refers to the average number of days that inventory remains in stock before being sold or used. This metric is crucial in determining the efficiency of a company's inventory management system and identifying areas for improvement. In this article, we will delve into the inventory days formula, its significance, and how it can be used to optimize inventory management.

The inventory days formula is a simple yet powerful tool that helps businesses calculate the average number of days their inventory remains in stock. This formula is essential in determining the liquidity of a company's inventory and identifying potential bottlenecks in the supply chain. By understanding the inventory days formula and its application, businesses can make informed decisions about their inventory management strategies, reduce costs, and improve their overall profitability.

Effective inventory management is critical in today's fast-paced business environment, where companies must be able to respond quickly to changing market conditions and customer demands. The inventory days formula provides businesses with a valuable metric that can be used to evaluate their inventory management performance and identify areas for improvement. By analyzing their inventory days, companies can determine whether they are holding too much inventory, which can lead to waste and unnecessary costs, or too little inventory, which can result in stockouts and lost sales.

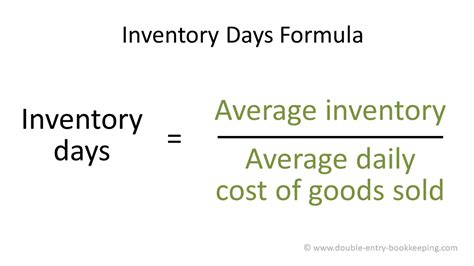

What is the Inventory Days Formula?

The inventory days formula, also known as the days inventory outstanding (DIO) formula, is calculated by dividing the average inventory by the cost of goods sold per day. The formula is as follows: Inventory Days = (Average Inventory / Cost of Goods Sold) x 365. This formula provides businesses with a simple and effective way to calculate the average number of days their inventory remains in stock.

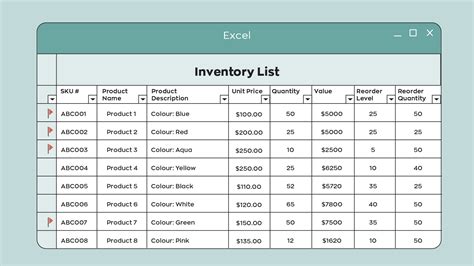

Calculating Average Inventory

To calculate the average inventory, businesses need to add the beginning and ending inventory levels for a given period and divide by 2. This provides an average inventory level that can be used in the inventory days formula. For example, if the beginning inventory is $100,000 and the ending inventory is $120,000, the average inventory would be ($100,000 + $120,000) / 2 = $110,000.Calculating Cost of Goods Sold per Day

To calculate the cost of goods sold per day, businesses need to divide the total cost of goods sold for a given period by the number of days in that period. For example, if the total cost of goods sold for a year is $1,000,000, the cost of goods sold per day would be $1,000,000 / 365 = $2,740.Importance of Inventory Days Formula

The inventory days formula is essential in determining the efficiency of a company's inventory management system. By calculating the average number of days their inventory remains in stock, businesses can identify potential bottlenecks in the supply chain and make informed decisions about their inventory management strategies. A high inventory days ratio may indicate that a company is holding too much inventory, which can lead to waste and unnecessary costs. On the other hand, a low inventory days ratio may indicate that a company is holding too little inventory, which can result in stockouts and lost sales.

Benefits of Inventory Days Formula

The inventory days formula provides businesses with several benefits, including: * Improved inventory management: By calculating the average number of days their inventory remains in stock, businesses can identify potential bottlenecks in the supply chain and make informed decisions about their inventory management strategies. * Reduced costs: By minimizing inventory levels and optimizing inventory management, businesses can reduce their costs and improve their profitability. * Increased efficiency: The inventory days formula helps businesses to streamline their inventory management processes, reducing waste and improving overall efficiency. * Better decision-making: The inventory days formula provides businesses with a valuable metric that can be used to evaluate their inventory management performance and make informed decisions about their inventory management strategies.How to Optimize Inventory Management using Inventory Days Formula

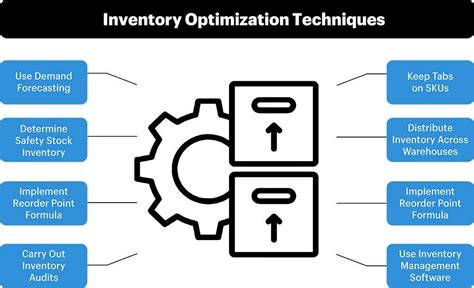

To optimize inventory management using the inventory days formula, businesses should follow these steps:

- Calculate the inventory days ratio: Use the inventory days formula to calculate the average number of days your inventory remains in stock.

- Analyze the results: Compare your inventory days ratio to industry benchmarks and identify potential bottlenecks in the supply chain.

- Implement inventory management strategies: Based on the results of your analysis, implement inventory management strategies that minimize inventory levels and optimize inventory management.

- Monitor and adjust: Continuously monitor your inventory days ratio and adjust your inventory management strategies as needed.

Common Inventory Management Strategies

Some common inventory management strategies that businesses can use to optimize their inventory management include: * Just-in-time (JIT) inventory management: This strategy involves ordering and receiving inventory just in time to meet customer demand. * Economic order quantity (EOQ) inventory management: This strategy involves ordering inventory in quantities that minimize total inventory costs. * Drop shipping: This strategy involves shipping products directly from the supplier to the customer, eliminating the need for inventory storage.Inventory Days Formula Examples

Here are some examples of how the inventory days formula can be used in real-world scenarios:

- Example 1: A company has an average inventory of $100,000 and a cost of goods sold of $1,000,000 per year. Using the inventory days formula, the company's inventory days ratio would be (100,000 / 1,000,000) x 365 = 36.5 days.

- Example 2: A company has an average inventory of $50,000 and a cost of goods sold of $500,000 per year. Using the inventory days formula, the company's inventory days ratio would be (50,000 / 500,000) x 365 = 36.5 days.

Inventory Days Formula Limitations

While the inventory days formula is a valuable tool for evaluating inventory management performance, it has some limitations. For example: * The formula assumes that the cost of goods sold is constant over the period being measured. * The formula does not take into account seasonal fluctuations in demand. * The formula does not account for inventory obsolescence or waste.Gallery of Inventory Management

Inventory Management Image Gallery

What is the inventory days formula?

+The inventory days formula is a metric that calculates the average number of days inventory remains in stock before being sold or used. It is calculated by dividing the average inventory by the cost of goods sold per day and multiplying by 365.

Why is the inventory days formula important?

+The inventory days formula is important because it helps businesses evaluate their inventory management performance, identify potential bottlenecks in the supply chain, and make informed decisions about their inventory management strategies.

How can I optimize my inventory management using the inventory days formula?

+To optimize your inventory management using the inventory days formula, you should calculate your inventory days ratio, analyze the results, implement inventory management strategies that minimize inventory levels and optimize inventory management, and continuously monitor and adjust your inventory management strategies as needed.

What are some common inventory management strategies that I can use to optimize my inventory management?

+Some common inventory management strategies that you can use to optimize your inventory management include just-in-time (JIT) inventory management, economic order quantity (EOQ) inventory management, and drop shipping.

What are the limitations of the inventory days formula?

+The inventory days formula has some limitations, including the assumption that the cost of goods sold is constant over the period being measured, not taking into account seasonal fluctuations in demand, and not accounting for inventory obsolescence or waste.

In conclusion, the inventory days formula is a valuable tool that businesses can use to evaluate their inventory management performance and make informed decisions about their inventory management strategies. By understanding the inventory days formula and its application, businesses can optimize their inventory management, reduce costs, and improve their overall profitability. We hope that this article has provided you with a comprehensive understanding of the inventory days formula and its significance in inventory management. If you have any further questions or would like to share your experiences with inventory management, please do not hesitate to comment below. Additionally, if you found this article informative, please share it with your colleagues and friends who may benefit from it.