Intro

Streamline inventory management with a sample Excel template, featuring inventory format examples, stock tracking, and asset management tools, to optimize logistics and warehouse operations efficiently.

Effective inventory management is crucial for businesses of all sizes, as it directly impacts their profitability, customer satisfaction, and overall operational efficiency. A well-organized inventory system helps in tracking stock levels, monitoring product movements, and making informed decisions about replenishments and sales strategies. One of the most versatile and widely used tools for managing inventory is Microsoft Excel, due to its flexibility, ease of use, and powerful analytical capabilities. In this article, we will explore the importance of inventory management, how to create an inventory format sample using Excel, and delve into the benefits and best practices of using such a template.

Inventory management encompasses a broad range of activities, including ordering, storing, and tracking inventory. It requires a systematic approach to ensure that the right products are available in the right quantities at the right time. Without an effective inventory management system, businesses risk facing stockouts, overstocking, and obsolescence, all of which can lead to significant financial losses and damage to their reputation. Therefore, implementing a robust inventory management system, such as one based on an Excel template, is essential for maintaining a competitive edge in today's fast-paced business environment.

Introduction to Inventory Management Templates

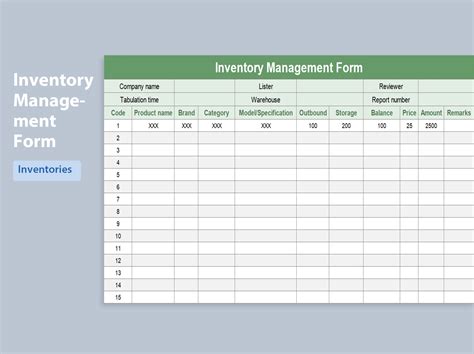

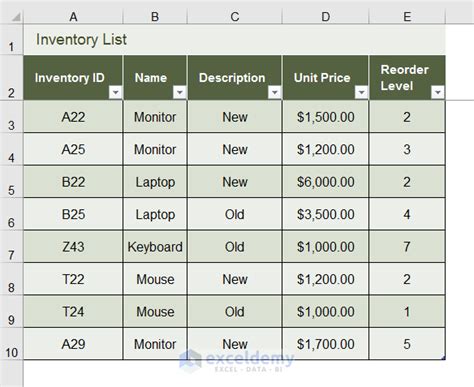

Inventory management templates are pre-designed spreadsheets that provide a structured format for organizing and analyzing inventory data. These templates can be customized to fit the specific needs of a business, allowing for the easy tracking of inventory levels, monitoring of stock movements, and identification of trends and patterns. By using an inventory management template, businesses can streamline their inventory processes, reduce errors, and make more accurate forecasts.

Benefits of Using Inventory Management Templates

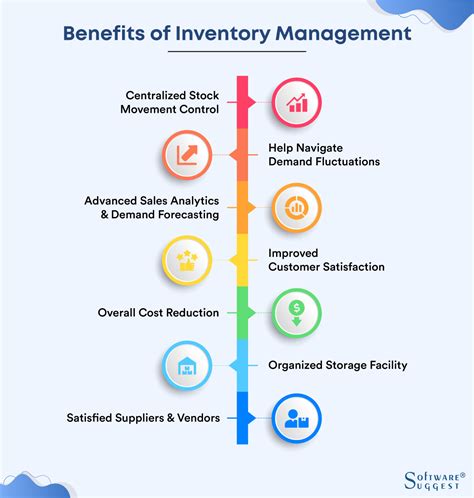

The benefits of using inventory management templates are numerous. They include:

- Improved Accuracy: By automating many of the tasks involved in inventory tracking, the likelihood of human error is significantly reduced.

- Enhanced Visibility: Inventory management templates provide real-time data on stock levels, allowing businesses to make informed decisions quickly.

- Increased Efficiency: Automating inventory management processes saves time and resources, enabling businesses to focus on core activities.

- Better Forecasting: With accurate and up-to-date inventory data, businesses can forecast demand more effectively, reducing the risk of overstocking or understocking.

- Cost Savings: Effective inventory management can lead to significant cost savings by minimizing waste, reducing the need for emergency orders, and optimizing storage space.

Creating an Inventory Format Sample in Excel

Creating an inventory format sample in Excel involves several steps:

- Setting Up the Spreadsheet: Start by opening a new Excel spreadsheet and setting up columns for relevant inventory information such as item name, description, quantity, unit price, total value, and location.

- Formatting the Template: Use Excel's formatting options to make the template visually appealing and easy to read. This can include using headers, footers, and conditional formatting.

- Adding Formulas and Functions: Utilize Excel's formulas and functions to automate calculations such as total inventory value and quantity totals.

- Implementing Data Validation: Use data validation to restrict input to certain ranges or formats, helping to prevent errors.

- Testing the Template: Before using the template for actual inventory management, test it with sample data to ensure it functions as expected.

Best Practices for Inventory Management

Best practices for inventory management include:

- Regular Audits: Conduct regular inventory audits to ensure the accuracy of inventory records.

- First-In, First-Out (FIFO) Method: Implement the FIFO method to ensure that older stock is sold or used before newer stock, reducing the risk of obsolescence.

- Inventory Classification: Classify inventory into categories based on value, velocity, or other relevant criteria to prioritize management efforts.

- Supply Chain Optimization: Work closely with suppliers to optimize lead times, reduce variability, and improve the overall efficiency of the supply chain.

- Continuous Improvement: Regularly review and refine inventory management processes to adapt to changing business needs and improve performance.

Common Inventory Management Mistakes

Common mistakes in inventory management include:

- Inadequate Forecasting: Failing to accurately forecast demand can lead to overstocking or understocking.

- Insufficient Training: Not providing adequate training to staff on inventory management procedures can lead to errors and inefficiencies.

- Lack of Automation: Relying too heavily on manual processes can lead to errors and inefficiencies.

- Poor Inventory Tracking: Failing to accurately track inventory movements can lead to discrepancies and loss.

- Ineffective Use of Space: Not optimizing storage space can lead to wasted resources and reduced efficiency.

Future of Inventory Management

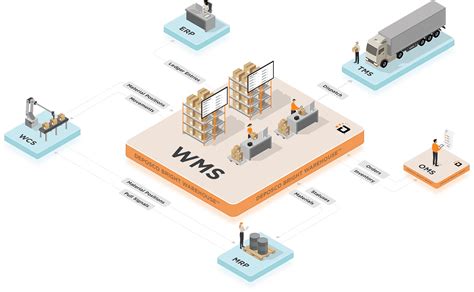

The future of inventory management is likely to be shaped by technologies such as artificial intelligence (AI), the Internet of Things (IoT), and blockchain. These technologies promise to further automate inventory management processes, improve accuracy, and enhance visibility across the supply chain. As businesses continue to evolve and grow, the importance of effective inventory management will only continue to increase, making it essential for companies to stay ahead of the curve by adopting the latest tools and best practices.

Gallery of Inventory Management Images

Inventory Management Image Gallery

What is the importance of inventory management in business?

+Inventory management is crucial for businesses as it helps in maintaining the right stock levels, reducing costs, and improving customer satisfaction.

How can I create an effective inventory management system?

+To create an effective inventory management system, start by identifying your inventory needs, choosing the right software or tool, and implementing best practices such as regular audits and the FIFO method.

What are the common mistakes in inventory management?

+Common mistakes include inadequate forecasting, insufficient training, lack of automation, poor inventory tracking, and ineffective use of space.

In conclusion, effective inventory management is the backbone of any successful business, enabling companies to meet customer demand, reduce costs, and drive profitability. By understanding the importance of inventory management, creating a robust inventory format sample in Excel, and adopting best practices, businesses can navigate the complexities of inventory management with ease. Whether you're a small startup or a large corporation, investing in a well-structured inventory management system is essential for achieving long-term success. We invite you to share your thoughts on inventory management, ask questions, or explore how you can implement these strategies in your own business operations.