Intro

Boost efficiency with effective inventory management programs, utilizing strategic stock control, supply chain optimization, and warehouse management to minimize costs and maximize profitability.

The success of any business, regardless of its size or industry, heavily relies on its ability to manage inventory effectively. Inventory management is the process of overseeing the flow of goods, products, and materials from manufacturers to warehouses and eventually to end-users. It involves tracking, storing, and managing the inventory levels to ensure that the right products are available at the right time and in the right quantities. Effective inventory management programs are crucial for businesses to minimize costs, maximize profits, and provide excellent customer service.

In today's fast-paced and competitive business environment, companies face numerous challenges in managing their inventory. These challenges include fluctuating demand, supply chain disruptions, and increasing competition. To stay ahead of the competition, businesses need to implement effective inventory management programs that can help them to optimize their inventory levels, reduce waste, and improve customer satisfaction. With the help of advanced technology and innovative strategies, companies can streamline their inventory management processes and achieve their business goals.

The importance of effective inventory management cannot be overstated. It has a direct impact on a company's bottom line, as excess inventory can lead to unnecessary costs, while stockouts can result in lost sales and damaged customer relationships. Moreover, effective inventory management can help businesses to improve their supply chain operations, reduce lead times, and increase their overall efficiency. By implementing effective inventory management programs, companies can gain a competitive edge in the market and achieve long-term success.

Benefits of Effective Inventory Management

Effective inventory management programs offer numerous benefits to businesses, including reduced costs, improved customer service, and increased efficiency. Some of the key benefits of effective inventory management include:

- Reduced inventory costs: By optimizing inventory levels, businesses can minimize the costs associated with storing and maintaining excess inventory.

- Improved customer service: Effective inventory management ensures that products are available when customers need them, leading to increased customer satisfaction and loyalty.

- Increased efficiency: Streamlined inventory management processes can help businesses to reduce lead times, improve supply chain operations, and increase their overall efficiency.

- Better decision-making: With accurate and timely inventory data, businesses can make informed decisions about production, pricing, and inventory levels.

- Reduced waste: Effective inventory management can help businesses to minimize waste and reduce the risk of inventory becoming obsolete or damaged.

Key Components of Effective Inventory Management

Effective inventory management programs typically involve several key components, including:- Inventory tracking and monitoring: This involves using technology, such as barcode scanning and inventory management software, to track and monitor inventory levels in real-time.

- Demand forecasting: This involves analyzing historical data and market trends to predict future demand and optimize inventory levels accordingly.

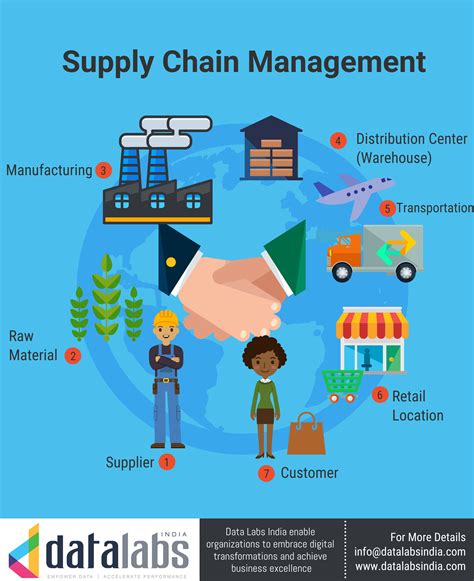

- Supply chain management: This involves managing the flow of goods, products, and materials from manufacturers to warehouses and eventually to end-users.

- Inventory optimization: This involves analyzing inventory data to identify areas for improvement and optimize inventory levels to meet customer demand.

Inventory Management Strategies

There are several inventory management strategies that businesses can use to optimize their inventory levels and improve their overall efficiency. Some of the most common inventory management strategies include:

- Just-in-time (JIT) inventory management: This involves ordering and receiving inventory just in time to meet customer demand, rather than storing excess inventory.

- Economic order quantity (EOQ) inventory management: This involves calculating the optimal order quantity to minimize inventory costs and maximize efficiency.

- Vendor-managed inventory (VMI) inventory management: This involves partnering with suppliers to manage inventory levels and optimize the supply chain.

- Drop shipping inventory management: This involves shipping products directly from the supplier to the customer, rather than storing inventory in a warehouse.

Best Practices for Inventory Management

To implement effective inventory management programs, businesses should follow several best practices, including:- Conducting regular inventory audits to ensure accuracy and identify areas for improvement.

- Implementing inventory management software to track and monitor inventory levels in real-time.

- Analyzing historical data and market trends to predict future demand and optimize inventory levels.

- Partnering with suppliers to manage inventory levels and optimize the supply chain.

- Continuously monitoring and evaluating inventory management processes to identify areas for improvement.

Technology and Inventory Management

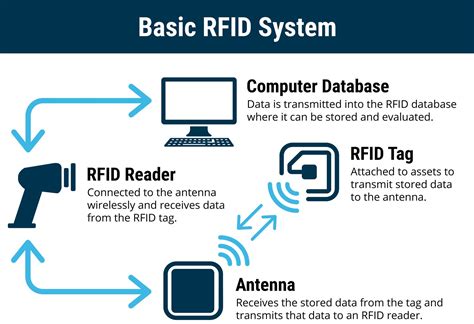

Technology plays a crucial role in effective inventory management, enabling businesses to track and monitor inventory levels in real-time, analyze historical data, and optimize inventory levels to meet customer demand. Some of the most common inventory management technologies include:

- Inventory management software: This involves using software to track and monitor inventory levels, analyze historical data, and optimize inventory levels.

- Barcode scanning: This involves using barcode scanners to track and monitor inventory levels in real-time.

- Radio-frequency identification (RFID) technology: This involves using RFID tags to track and monitor inventory levels in real-time.

- Cloud-based inventory management: This involves using cloud-based software to track and monitor inventory levels, analyze historical data, and optimize inventory levels.

Common Inventory Management Mistakes

Despite the importance of effective inventory management, many businesses make common mistakes that can lead to inventory management problems. Some of the most common inventory management mistakes include:- Overstocking: This involves ordering too much inventory, leading to excess inventory and unnecessary costs.

- Understocking: This involves ordering too little inventory, leading to stockouts and lost sales.

- Poor inventory tracking: This involves failing to track and monitor inventory levels in real-time, leading to inventory management problems.

- Inadequate supply chain management: This involves failing to manage the flow of goods, products, and materials from manufacturers to warehouses and eventually to end-users.

Inventory Management and Customer Service

Effective inventory management is critical to providing excellent customer service, as it ensures that products are available when customers need them. Some of the ways that inventory management can impact customer service include:

- Product availability: Effective inventory management ensures that products are available when customers need them, leading to increased customer satisfaction and loyalty.

- Order fulfillment: Effective inventory management enables businesses to fulfill orders quickly and efficiently, leading to increased customer satisfaction and loyalty.

- Returns and refunds: Effective inventory management can help businesses to minimize returns and refunds by ensuring that products are accurate and of high quality.

Measuring Inventory Management Performance

To evaluate the effectiveness of inventory management programs, businesses should measure several key performance indicators (KPIs), including:- Inventory turnover: This involves measuring the number of times that inventory is sold and replaced within a given period.

- Inventory levels: This involves measuring the amount of inventory on hand at any given time.

- Fill rates: This involves measuring the percentage of orders that are filled from existing inventory.

- Order fulfillment rates: This involves measuring the percentage of orders that are fulfilled quickly and efficiently.

Future of Inventory Management

The future of inventory management is likely to be shaped by several trends and technologies, including:

- Artificial intelligence (AI) and machine learning (ML): These technologies can help businesses to analyze historical data and market trends to predict future demand and optimize inventory levels.

- Internet of Things (IoT) devices: These devices can help businesses to track and monitor inventory levels in real-time, using sensors and other technologies to detect inventory levels and optimize inventory management.

- Blockchain technology: This technology can help businesses to track and monitor inventory levels in real-time, using a decentralized and secure ledger to record inventory transactions.

- Cloud-based inventory management: This technology can help businesses to track and monitor inventory levels in real-time, using cloud-based software to analyze historical data and optimize inventory levels.

Conclusion and Recommendations

In conclusion, effective inventory management is critical to the success of any business, regardless of its size or industry. By implementing effective inventory management programs, businesses can minimize costs, maximize profits, and provide excellent customer service. To achieve effective inventory management, businesses should follow several best practices, including conducting regular inventory audits, implementing inventory management software, and partnering with suppliers to manage inventory levels and optimize the supply chain. By staying up-to-date with the latest trends and technologies in inventory management, businesses can stay ahead of the competition and achieve long-term success.Inventory Management Image Gallery

What is inventory management?

+Inventory management is the process of overseeing the flow of goods, products, and materials from manufacturers to warehouses and eventually to end-users.

Why is inventory management important?

+Inventory management is important because it helps businesses to minimize costs, maximize profits, and provide excellent customer service.

What are the benefits of effective inventory management?

+The benefits of effective inventory management include reduced costs, improved customer service, and increased efficiency.

What are the common inventory management mistakes?

+The common inventory management mistakes include overstocking, understocking, poor inventory tracking, and inadequate supply chain management.

How can businesses improve their inventory management?

+Businesses can improve their inventory management by conducting regular inventory audits, implementing inventory management software, and partnering with suppliers to manage inventory levels and optimize the supply chain.

We hope that this article has provided you with a comprehensive understanding of effective inventory management programs and their importance in business. If you have any further questions or would like to share your experiences with inventory management, please do not hesitate to comment below. Additionally, if you found this article informative and helpful, please feel free to share it with your friends and colleagues.