Intro

Boost efficiency with 5 inventory management tips, including stock control, supply chain optimization, and warehouse management, to reduce costs and improve logistics, using effective inventory tracking and forecasting techniques.

Effective inventory management is crucial for businesses to remain competitive and profitable in today's fast-paced market. It involves balancing the need to have enough stock on hand to meet customer demand with the need to avoid overstocking, which can lead to waste and unnecessary costs. Inventory management tips can help businesses optimize their inventory levels, reduce costs, and improve customer satisfaction. In this article, we will discuss five inventory management tips that can help businesses achieve these goals.

Inventory management is a critical aspect of supply chain management that involves planning, organizing, and controlling the flow of goods from raw materials to finished products. It requires careful planning and execution to ensure that the right products are available in the right quantities at the right time. Effective inventory management can help businesses reduce costs, improve customer satisfaction, and increase profitability. On the other hand, poor inventory management can lead to stockouts, overstocking, and waste, which can have negative impacts on a business's bottom line.

The importance of inventory management cannot be overstated. It is a critical component of a business's overall strategy and can have a significant impact on its profitability and competitiveness. Businesses that fail to manage their inventory effectively can experience a range of problems, including stockouts, overstocking, and waste. These problems can lead to lost sales, damaged customer relationships, and reduced profitability. On the other hand, businesses that manage their inventory effectively can experience a range of benefits, including reduced costs, improved customer satisfaction, and increased profitability.

Understanding Inventory Management

Types of Inventory Management

There are several types of inventory management, each with its own strengths and weaknesses. JIT inventory management involves ordering and receiving inventory just in time to meet customer demand. This approach can help businesses reduce inventory levels and minimize waste, but it requires careful planning and execution to ensure that the right products are available at the right time. MRP involves planning and controlling the flow of goods from raw materials to finished products. This approach can help businesses optimize their inventory levels and reduce waste, but it requires significant planning and resources. EOQ involves ordering inventory in quantities that minimize total inventory costs. This approach can help businesses reduce inventory costs, but it requires careful planning and execution to ensure that the right products are available at the right time.Inventory Management Tips

Implementing Inventory Management Tips

Implementing inventory management tips requires careful planning and execution. Businesses should start by conducting regular inventory audits to ensure that inventory levels are accurate and up-to-date. They should also implement a FIFO inventory management system to minimize waste and reduce inventory costs. Inventory management software can be used to track and manage inventory levels, automate inventory tracking, and optimize inventory ordering. VMI systems can be used to allow suppliers to manage inventory levels on behalf of the business. Finally, businesses should use data and analytics to optimize inventory levels, reduce waste, and improve customer satisfaction.Benefits of Inventory Management

Best Practices for Inventory Management

There are several best practices for inventory management that can help businesses optimize their inventory levels, reduce costs, and improve customer satisfaction. These include: * Conducting regular inventory audits * Implementing a FIFO inventory management system * Using inventory management software * Implementing a VMI system * Using data and analytics to optimize inventory levels * Reducing inventory levels * Optimizing inventory ordering * Minimizing wasteCommon Inventory Management Mistakes

Avoiding Inventory Management Mistakes

Avoiding inventory management mistakes requires careful planning and execution. Businesses should start by conducting regular inventory audits to ensure that inventory levels are accurate and up-to-date. They should also implement a FIFO inventory management system to minimize waste and reduce inventory costs. Inventory management software can be used to track and manage inventory levels, automate inventory tracking, and optimize inventory ordering. VMI systems can be used to allow suppliers to manage inventory levels on behalf of the business. Finally, businesses should use data and analytics to optimize inventory levels, reduce waste, and improve customer satisfaction.Inventory Management Tools

Using Inventory Management Tools

Using inventory management tools requires careful planning and execution. Businesses should start by selecting the right inventory management software for their needs. They should also implement barcode scanners, RFID tags, and inventory tracking systems to track and manage inventory levels. VMI systems can be used to allow suppliers to manage inventory levels on behalf of the business. Finally, businesses should use data and analytics tools to optimize inventory levels, reduce waste, and improve customer satisfaction.Inventory Management Image Gallery

What is inventory management?

+Inventory management is the process of planning, organizing, and controlling the flow of goods from raw materials to finished products.

Why is inventory management important?

+Inventory management is important because it can help businesses reduce costs, improve customer satisfaction, and increase profitability.

What are some common inventory management mistakes?

+Some common inventory management mistakes include overstocking, understocking, failing to conduct regular inventory audits, and failing to implement a FIFO inventory management system.

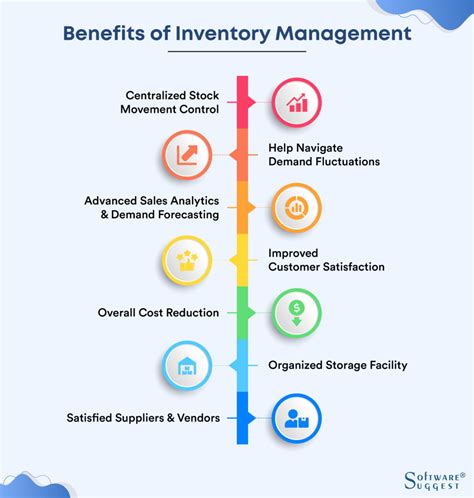

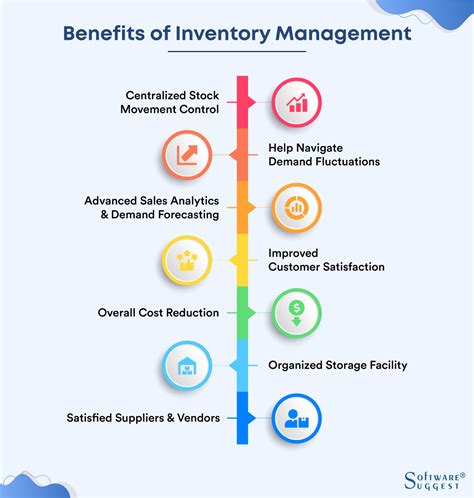

What are some benefits of inventory management?

+Some benefits of inventory management include reduced inventory costs, improved customer satisfaction, increased profitability, minimized waste, reduced inventory levels, and optimized inventory ordering.

What are some inventory management tools?

+Some inventory management tools include inventory management software, barcode scanners, RFID tags, inventory tracking systems, VMI systems, and data and analytics tools.

In conclusion, effective inventory management is crucial for businesses to remain competitive and profitable in today's fast-paced market. By implementing inventory management tips, businesses can optimize their inventory levels, reduce costs, and improve customer satisfaction. It is essential for businesses to understand the importance of inventory management, the types of inventory management, and the benefits of inventory management. By avoiding common inventory management mistakes and using inventory management tools, businesses can achieve their goals and stay competitive in the market. We hope this article has provided you with valuable insights and information on inventory management. If you have any questions or comments, please feel free to share them with us. Additionally, if you found this article helpful, please share it with others who may benefit from it.