Intro

Boost efficiency with 5 inventory management tips, including stock control, supply chain optimization, and warehouse management, to reduce costs and improve logistics, using effective inventory tracking and forecasting techniques.

Effective inventory management is crucial for businesses to maintain a competitive edge in the market. It involves managing the flow of goods, products, and materials from procurement to delivery, ensuring that the right products are available at the right time and in the right quantities. Inventory management tips can help businesses streamline their operations, reduce costs, and improve customer satisfaction. In this article, we will discuss five essential inventory management tips that can help businesses achieve their goals.

Inventory management is a critical aspect of business operations, and its importance cannot be overstated. A well-managed inventory can help businesses reduce waste, lower costs, and improve efficiency. On the other hand, poor inventory management can lead to stockouts, overstocking, and lost sales. With the rise of e-commerce and changing consumer behaviors, businesses need to be more agile and responsive to customer demands. Effective inventory management can help businesses stay ahead of the competition and achieve long-term success.

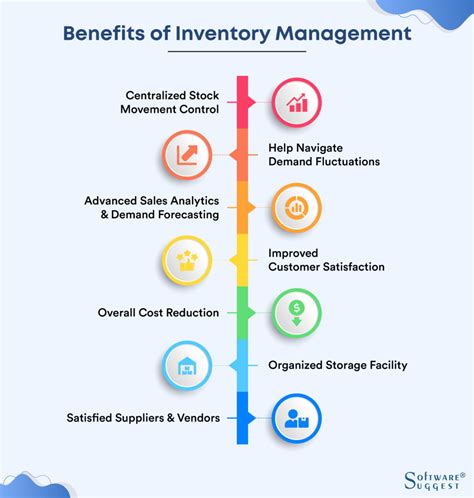

The benefits of effective inventory management are numerous. It can help businesses reduce inventory costs, improve cash flow, and increase profitability. By optimizing inventory levels, businesses can minimize waste and reduce the risk of stockouts. Effective inventory management can also help businesses improve their supply chain operations, reduce lead times, and enhance customer satisfaction. With the right inventory management strategies, businesses can stay competitive, adapt to changing market conditions, and achieve their goals.

Understanding Inventory Management

Types of Inventory

There are several types of inventory that businesses need to manage, including: * Raw materials: These are the materials used to produce products, such as components, ingredients, and supplies. * Work-in-progress: This refers to products that are in the production process, but not yet completed. * Finished goods: These are the final products that are ready for sale and distribution. * Maintenance, repair, and operations (MRO) inventory: This refers to the supplies and materials used to maintain and repair equipment and facilities.Inventory Management Tips

Best Practices for Inventory Management

Here are some best practices for inventory management: * **Track inventory levels in real-time**: This can help businesses monitor inventory levels, detect discrepancies, and optimize inventory levels. * **Use barcode scanning and RFID technology**: This can help businesses track inventory levels, monitor stock movements, and optimize inventory levels. * **Implement a vendor-managed inventory (VMI) system**: This can help businesses reduce inventory costs, minimize waste, and improve efficiency. * **Conduct regular inventory audits**: This can help businesses identify discrepancies, detect theft, and optimize inventory levels.Benefits of Effective Inventory Management

Common Inventory Management Mistakes

Here are some common inventory management mistakes that businesses should avoid: * **Overstocking**: This can lead to waste, obsolescence, and increased inventory costs. * **Understocking**: This can lead to stockouts, lost sales, and reduced customer satisfaction. * **Poor inventory tracking**: This can lead to discrepancies, theft, and reduced inventory accuracy. * **Inadequate inventory management software**: This can lead to reduced inventory visibility, increased inventory costs, and reduced efficiency.Inventory Management Software

Inventory Management Techniques

Here are some common inventory management techniques: * **Just-in-time (JIT) inventory management**: This involves ordering and receiving inventory just in time to meet customer demands. * **Economic order quantity (EOQ)**: This involves ordering inventory in quantities that minimize inventory costs and maximize efficiency. * **Vendor-managed inventory (VMI)**: This involves partnering with suppliers to manage inventory levels and optimize inventory management. * **Drop shipping**: This involves shipping products directly from the supplier to the customer, eliminating the need for inventory storage and handling.Conclusion and Future Directions

Inventory Management Image Gallery

What is inventory management?

+Inventory management involves managing the entire inventory lifecycle, from procurement to delivery. It requires businesses to track inventory levels, monitor stock movements, and optimize inventory levels to meet customer demands.

Why is inventory management important?

+Inventory management is important because it can help businesses reduce waste, lower costs, and improve efficiency. By optimizing inventory levels, businesses can minimize waste, reduce inventory costs, and improve profitability.

What are some common inventory management mistakes?

+Some common inventory management mistakes include overstocking, understocking, poor inventory tracking, and inadequate inventory management software. These mistakes can lead to waste, obsolescence, and reduced customer satisfaction.

How can businesses improve their inventory management?

+Businesses can improve their inventory management by implementing the right inventory management strategies, leveraging inventory management software, and following best practices. They can also conduct regular inventory audits, monitor and analyze inventory levels, and optimize inventory levels to meet customer demands.

What is the future of inventory management?

+The future of inventory management involves the use of advanced technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies can help businesses optimize inventory levels, improve inventory tracking, and enhance customer satisfaction.

We hope that this article has provided you with valuable insights into inventory management and its importance for businesses. By implementing the right inventory management strategies and following best practices, businesses can reduce waste, lower costs, and improve efficiency. If you have any questions or comments, please feel free to share them with us. We would be happy to hear from you and provide further guidance on inventory management. Additionally, if you found this article helpful, please share it with others who may benefit from it. Let's work together to improve inventory management and drive business success.