Intro

Boost efficiency with 5 Ways Inventory Monitoring, utilizing stock tracking, warehouse management, and supply chain optimization to minimize losses and maximize profits.

Effective inventory management is crucial for businesses to maintain a competitive edge in the market. One of the key components of inventory management is inventory monitoring, which involves tracking and controlling the flow of goods in and out of a warehouse or storage facility. In this article, we will explore the importance of inventory monitoring and discuss five ways to implement it effectively.

Inventory monitoring is essential for businesses to ensure that they have the right amount of stock on hand to meet customer demand. It helps to prevent stockouts, overstocking, and dead stock, which can all have a significant impact on the bottom line. By monitoring inventory levels, businesses can identify trends and patterns in customer demand, allowing them to make informed decisions about production and purchasing. Additionally, inventory monitoring can help businesses to reduce waste, minimize losses, and improve overall efficiency.

In recent years, the importance of inventory monitoring has become even more pronounced. With the rise of e-commerce and omnichannel retailing, businesses need to be able to respond quickly to changing customer demand. Inventory monitoring enables businesses to do just that, by providing real-time visibility into inventory levels and allowing them to make rapid adjustments as needed. Furthermore, inventory monitoring can help businesses to improve their supply chain resilience, by identifying potential disruptions and taking proactive steps to mitigate them.

Introduction to Inventory Monitoring

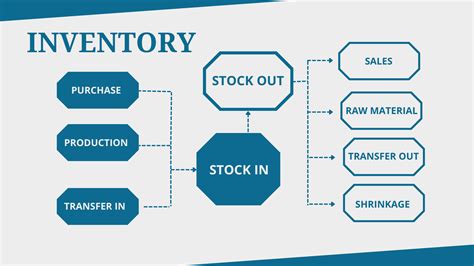

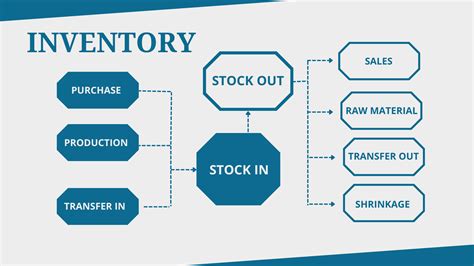

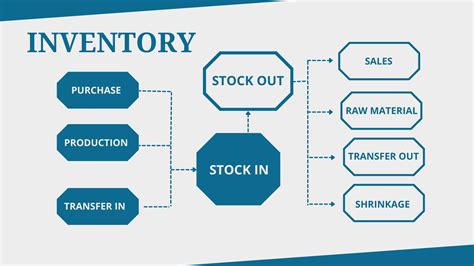

Inventory monitoring involves tracking and controlling the flow of goods in and out of a warehouse or storage facility. It requires the use of specialized software and hardware, such as barcode scanners and inventory management systems. By using these tools, businesses can gain real-time visibility into their inventory levels, allowing them to make informed decisions about production and purchasing.

Benefits of Inventory Monitoring

The benefits of inventory monitoring are numerous. Some of the most significant advantages include: * Improved inventory accuracy: Inventory monitoring helps to ensure that inventory levels are accurate and up-to-date, reducing the risk of stockouts and overstocking. * Increased efficiency: By automating the inventory tracking process, businesses can free up staff to focus on more strategic tasks. * Reduced waste: Inventory monitoring helps to identify slow-moving or dead stock, allowing businesses to take proactive steps to reduce waste and minimize losses. * Improved customer service: By ensuring that the right products are available at the right time, businesses can improve customer satisfaction and loyalty.5 Ways to Implement Inventory Monitoring

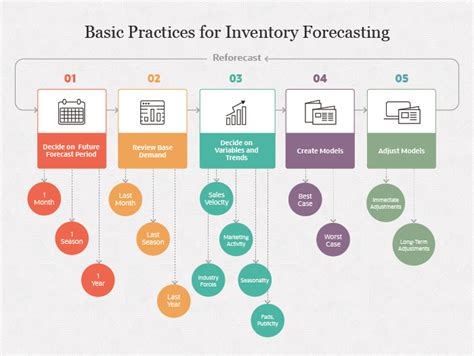

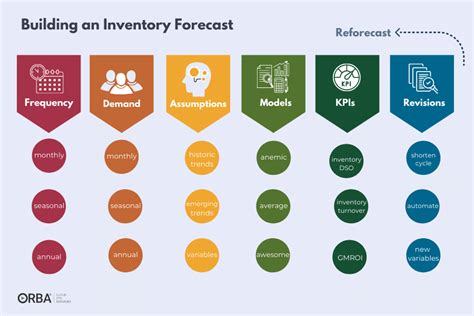

There are several ways to implement inventory monitoring, depending on the specific needs and requirements of the business. Here are five ways to get started:

- Use Inventory Management Software: Inventory management software is a specialized tool that helps businesses to track and control their inventory levels. It can be used to automate the inventory tracking process, providing real-time visibility into inventory levels and allowing businesses to make informed decisions about production and purchasing.

- Implement Barcode Scanning: Barcode scanning is a simple and effective way to track inventory levels. By using barcode scanners to track the movement of goods in and out of the warehouse, businesses can gain real-time visibility into their inventory levels and reduce the risk of errors.

- Conduct Regular Inventory Audits: Regular inventory audits are an essential part of inventory monitoring. By conducting regular audits, businesses can ensure that their inventory levels are accurate and up-to-date, reducing the risk of stockouts and overstocking.

- Use RFID Technology: RFID (Radio Frequency Identification) technology is a advanced way to track inventory levels. By using RFID tags to track the movement of goods in and out of the warehouse, businesses can gain real-time visibility into their inventory levels and reduce the risk of errors.

- Implement a Just-in-Time (JIT) System: A JIT system is a inventory management strategy that involves ordering and receiving inventory just in time to meet customer demand. By implementing a JIT system, businesses can reduce the risk of overstocking and dead stock, improving overall efficiency and reducing waste.

Best Practices for Inventory Monitoring

To get the most out of inventory monitoring, businesses should follow best practices such as: * **Set Clear Goals and Objectives**: Businesses should set clear goals and objectives for their inventory monitoring system, such as improving inventory accuracy or reducing waste. * **Choose the Right Technology**: Businesses should choose the right technology for their inventory monitoring system, such as inventory management software or barcode scanners. * **Train Staff**: Businesses should train staff on how to use the inventory monitoring system, ensuring that they understand how to track and control inventory levels. * **Monitor and Evaluate**: Businesses should regularly monitor and evaluate their inventory monitoring system, making adjustments as needed to ensure that it is working effectively.Common Challenges in Inventory Monitoring

Despite the many benefits of inventory monitoring, there are several common challenges that businesses may face. Some of the most significant challenges include:

- Data Accuracy: Ensuring that inventory data is accurate and up-to-date can be a challenge, particularly in large and complex supply chains.

- System Integration: Integrating inventory monitoring systems with other business systems, such as enterprise resource planning (ERP) systems, can be a challenge.

- Staff Training: Training staff on how to use inventory monitoring systems can be a challenge, particularly in businesses with high staff turnover.

- Cost: Implementing an inventory monitoring system can be costly, particularly for small and medium-sized businesses.

Solutions to Common Challenges

To overcome common challenges in inventory monitoring, businesses can use solutions such as: * **Data Validation**: Validating inventory data to ensure that it is accurate and up-to-date. * **System Integration Tools**: Using system integration tools to integrate inventory monitoring systems with other business systems. * **Staff Training Programs**: Implementing staff training programs to ensure that staff understand how to use inventory monitoring systems. * **Cost-Benefit Analysis**: Conducting a cost-benefit analysis to determine the return on investment (ROI) of implementing an inventory monitoring system.Future of Inventory Monitoring

The future of inventory monitoring is likely to be shaped by advances in technology, such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies have the potential to revolutionize inventory monitoring, enabling businesses to track and control inventory levels in real-time and make predictions about future demand.

Trends in Inventory Monitoring

Some of the trends in inventory monitoring include: * **Increased Use of Automation**: Increased use of automation, such as robotics and machine learning, to track and control inventory levels. * **Greater Use of Data Analytics**: Greater use of data analytics to analyze inventory data and make predictions about future demand. * **More Focus on Sustainability**: More focus on sustainability, such as reducing waste and minimizing environmental impact. * **Greater Emphasis on Customer Experience**: Greater emphasis on customer experience, such as improving delivery times and reducing stockouts.Inventory Monitoring Image Gallery

What is inventory monitoring?

+Inventory monitoring is the process of tracking and controlling the flow of goods in and out of a warehouse or storage facility.

Why is inventory monitoring important?

+Inventory monitoring is important because it helps businesses to ensure that they have the right amount of stock on hand to meet customer demand, reducing the risk of stockouts and overstocking.

What are the benefits of inventory monitoring?

+The benefits of inventory monitoring include improved inventory accuracy, increased efficiency, reduced waste, and improved customer service.

How can businesses implement inventory monitoring?

+Businesses can implement inventory monitoring by using inventory management software, barcode scanning, regular inventory audits, RFID technology, and just-in-time (JIT) systems.

What are the common challenges in inventory monitoring?

+The common challenges in inventory monitoring include data accuracy, system integration, staff training, and cost.

In conclusion, inventory monitoring is a crucial aspect of inventory management that helps businesses to track and control their inventory levels, reducing the risk of stockouts and overstocking. By implementing inventory monitoring, businesses can improve their inventory accuracy, increase efficiency, reduce waste, and improve customer service. We hope this article has provided you with a comprehensive understanding of the importance of inventory monitoring and how to implement it effectively. If you have any further questions or would like to share your experiences with inventory monitoring, please don't hesitate to comment below. Additionally, if you found this article helpful, please share it with your network to help spread the knowledge.