Intro

Streamline stock management with an inventory spreadsheet example template, featuring automated tracking, inventory control, and stock level monitoring for efficient logistics and supply chain management.

Effective inventory management is crucial for businesses of all sizes, as it directly impacts profitability, customer satisfaction, and operational efficiency. An inventory spreadsheet is a fundamental tool that helps in organizing, tracking, and managing stock levels, orders, and storage. In this article, we will delve into the importance of inventory management, the benefits of using an inventory spreadsheet, and provide a comprehensive guide on how to create and utilize an inventory spreadsheet example template.

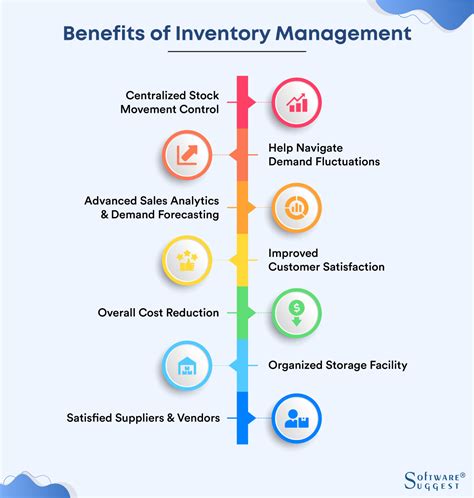

Inventory management encompasses a wide range of activities, including monitoring stock levels, tracking orders, managing storage, and optimizing inventory levels to meet customer demand while minimizing costs. Proper inventory management can lead to significant reductions in operational costs, improvements in customer service, and enhancements in overall business performance. On the other hand, poor inventory management can result in stockouts, overstocking, and wasted resources, ultimately affecting a company's bottom line and reputation.

The use of an inventory spreadsheet is a cost-effective and straightforward approach to managing inventory. It allows businesses to keep a detailed record of their stock, including quantities, locations, and statuses. An inventory spreadsheet can be customized to fit the specific needs of a business, making it an indispensable tool for small, medium, and large enterprises alike. With an inventory spreadsheet, businesses can easily track inventory movements, identify trends, and make informed decisions regarding inventory levels, supplier selection, and logistics.

Introduction to Inventory Spreadsheets

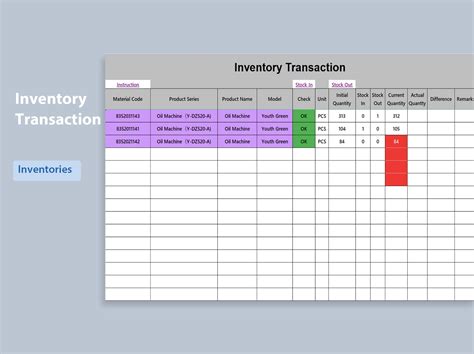

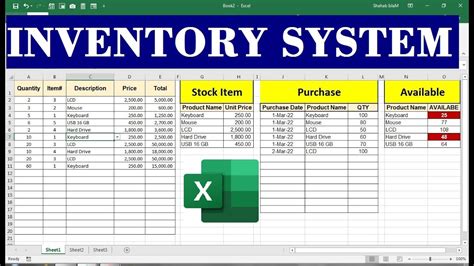

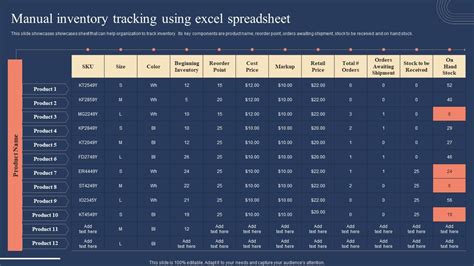

An inventory spreadsheet is essentially a table or database that stores information about the inventory of a business. It can be created using spreadsheet software like Microsoft Excel, Google Sheets, or LibreOffice Calc. The spreadsheet typically includes columns for item descriptions, item numbers, quantities, unit prices, total values, and locations. By organizing this data in a structured and accessible way, businesses can efficiently manage their inventory, reduce errors, and improve their overall inventory management processes.

Benefits of Using an Inventory Spreadsheet

The benefits of using an inventory spreadsheet are numerous and significant. Firstly, it enhances inventory accuracy by providing a centralized platform for tracking inventory levels, reducing discrepancies, and minimizing errors. Secondly, it improves inventory control by allowing businesses to set reorder points, track inventory movements, and optimize stock levels. Thirdly, it facilitates better decision-making by providing real-time data on inventory levels, trends, and supplier performance. Lastly, it increases operational efficiency by automating many inventory management tasks, freeing up staff to focus on higher-value activities.

Creating an Inventory Spreadsheet Example Template

Creating an inventory spreadsheet example template involves several steps. Firstly, identify the key information that needs to be tracked, such as item descriptions, quantities, locations, and statuses. Secondly, set up the spreadsheet structure, including the columns and rows that will be used to organize the data. Thirdly, enter the initial inventory data, either manually or by importing it from another source. Fourthly, customize the spreadsheet by adding formulas, charts, and filters to enhance its functionality and usability. Lastly, regularly update and maintain the spreadsheet to ensure that it remains accurate and relevant.

Steps to Implement an Inventory Spreadsheet

Implementing an inventory spreadsheet involves several key steps:

- Identify Inventory Needs: Determine what inventory items need to be tracked and what information is required for each item.

- Set Up the Spreadsheet: Create a spreadsheet with columns for item descriptions, quantities, locations, and statuses.

- Enter Initial Data: Enter the initial inventory data into the spreadsheet, either manually or by importing it from another source.

- Customize the Spreadsheet: Add formulas, charts, and filters to the spreadsheet to enhance its functionality and usability.

- Regularly Update and Maintain: Regularly update and maintain the spreadsheet to ensure that it remains accurate and relevant.

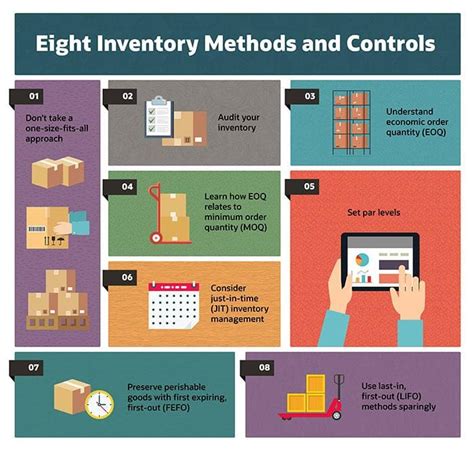

Best Practices for Inventory Management

Best practices for inventory management include:

- Regular Inventory Audits: Conduct regular inventory audits to ensure that the inventory records are accurate and up-to-date.

- Inventory Classification: Classify inventory items based on their value, usage, and lead time to prioritize inventory management efforts.

- Supplier Management: Develop strong relationships with suppliers to improve delivery times, reduce costs, and enhance quality.

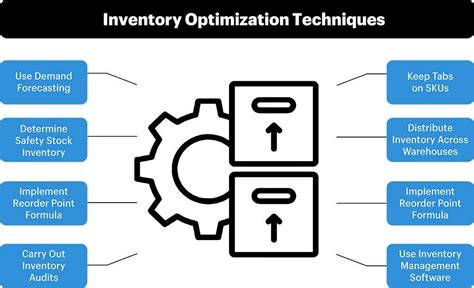

- Inventory Optimization: Optimize inventory levels based on demand forecasts, lead times, and supplier performance to minimize stockouts and overstocking.

Common Inventory Management Mistakes

Common inventory management mistakes include:

- Inaccurate Inventory Records: Failing to maintain accurate and up-to-date inventory records, leading to stockouts, overstocking, and wasted resources.

- Poor Supplier Management: Failing to develop strong relationships with suppliers, leading to poor delivery times, high costs, and low quality.

- Inadequate Inventory Classification: Failing to classify inventory items based on their value, usage, and lead time, leading to inefficient inventory management efforts.

- Lack of Inventory Optimization: Failing to optimize inventory levels based on demand forecasts, lead times, and supplier performance, leading to stockouts and overstocking.

Gallery of Inventory Management Examples

Inventory Management Image Gallery

What is inventory management?

+Inventory management refers to the process of managing and controlling the inventory levels of a business, including monitoring stock levels, tracking orders, managing storage, and optimizing inventory levels to meet customer demand while minimizing costs.

Why is inventory management important?

+Inventory management is important because it directly impacts profitability, customer satisfaction, and operational efficiency. Proper inventory management can lead to significant reductions in operational costs, improvements in customer service, and enhancements in overall business performance.

What are the benefits of using an inventory spreadsheet?

+The benefits of using an inventory spreadsheet include enhanced inventory accuracy, improved inventory control, better decision-making, and increased operational efficiency. An inventory spreadsheet provides a centralized platform for tracking inventory levels, reducing discrepancies, and minimizing errors.

In conclusion, effective inventory management is crucial for businesses of all sizes, and an inventory spreadsheet is a fundamental tool that can help in organizing, tracking, and managing stock levels, orders, and storage. By creating and utilizing an inventory spreadsheet example template, businesses can enhance inventory accuracy, improve inventory control, facilitate better decision-making, and increase operational efficiency. We invite you to share your experiences with inventory management and spreadsheet templates in the comments below. If you found this article helpful, please consider sharing it with your network to help others improve their inventory management practices.