Intro

Optimize inventory control with an effective inventory stock management system, utilizing stock tracking, warehouse management, and supply chain optimization to streamline operations and boost efficiency.

Inventory stock management is a critical aspect of any business, as it directly affects the company's profitability, customer satisfaction, and overall competitiveness. A well-designed inventory management system can help organizations reduce costs, improve efficiency, and enhance their ability to respond to changing market conditions. In this article, we will delve into the importance of inventory stock management, its benefits, and the key components of an effective inventory management system.

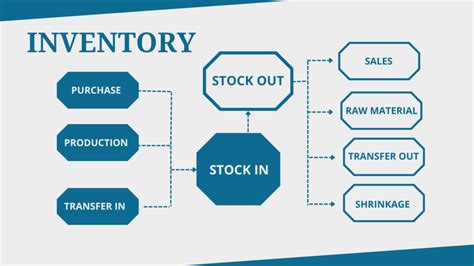

Inventory management refers to the process of planning, organizing, and controlling the flow of goods, products, or materials from raw materials to finished goods. It involves managing the inventory levels, tracking the movement of goods, and ensuring that the right products are available at the right time and in the right quantities. Effective inventory management is essential for businesses to minimize stockouts, overstocking, and obsolescence, which can result in significant financial losses.

The importance of inventory management cannot be overstated. A well-managed inventory system can help businesses reduce their inventory costs, improve their cash flow, and enhance their customer service. It can also help organizations to respond quickly to changes in market demand, reduce their lead times, and improve their overall competitiveness. On the other hand, poor inventory management can lead to stockouts, overstocking, and obsolescence, which can result in significant financial losses and damage to a company's reputation.

Benefits of Effective Inventory Management

Effective inventory management offers numerous benefits to businesses, including reduced inventory costs, improved cash flow, and enhanced customer service. Some of the key benefits of effective inventory management include:

- Reduced inventory costs: Effective inventory management can help businesses reduce their inventory costs by minimizing stockouts, overstocking, and obsolescence.

- Improved cash flow: By reducing inventory levels and minimizing stockouts, businesses can improve their cash flow and reduce their need for external financing.

- Enhanced customer service: Effective inventory management can help businesses improve their customer service by ensuring that products are available when customers need them.

- Improved supply chain management: Effective inventory management can help businesses improve their supply chain management by enabling them to respond quickly to changes in market demand and supply chain disruptions.

- Reduced lead times: Effective inventory management can help businesses reduce their lead times by enabling them to respond quickly to changes in market demand and supply chain disruptions.

Key Components of an Effective Inventory Management System

An effective inventory management system consists of several key components, including:- Inventory planning and forecasting: This involves forecasting demand and planning inventory levels to meet customer demand.

- Inventory tracking and monitoring: This involves tracking and monitoring inventory levels, movements, and stock levels.

- Inventory control: This involves controlling inventory levels, minimizing stockouts, and preventing overstocking.

- Inventory optimization: This involves optimizing inventory levels to minimize costs and maximize profitability.

- Supply chain management: This involves managing the flow of goods, products, or materials from raw materials to finished goods.

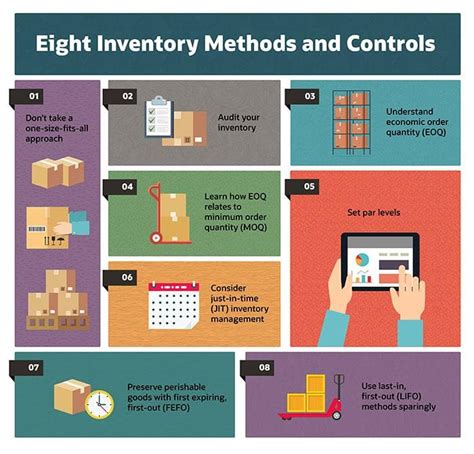

Inventory Management Techniques

There are several inventory management techniques that businesses can use to manage their inventory effectively. Some of the most common techniques include:

- Just-in-time (JIT) inventory management: This involves ordering and receiving inventory just in time to meet customer demand.

- Economic order quantity (EOQ) inventory management: This involves ordering inventory in quantities that minimize the total cost of inventory management.

- Vendor-managed inventory (VMI) inventory management: This involves allowing suppliers to manage inventory levels on behalf of the business.

- Drop shipping inventory management: This involves shipping products directly from the supplier to the customer without holding any inventory.

- Inventory classification: This involves classifying inventory into different categories based on their value, volume, and importance.

Inventory Management Software

Inventory management software is a critical component of an effective inventory management system. It can help businesses automate their inventory management processes, track and monitor inventory levels, and optimize their inventory levels to minimize costs and maximize profitability. Some of the key features of inventory management software include:- Inventory tracking and monitoring: This involves tracking and monitoring inventory levels, movements, and stock levels.

- Inventory reporting and analytics: This involves generating reports and analytics to help businesses optimize their inventory levels and minimize costs.

- Inventory optimization: This involves optimizing inventory levels to minimize costs and maximize profitability.

- Supply chain management: This involves managing the flow of goods, products, or materials from raw materials to finished goods.

- Integration with other business systems: This involves integrating inventory management software with other business systems, such as accounting and customer relationship management systems.

Best Practices for Inventory Management

There are several best practices that businesses can follow to manage their inventory effectively. Some of the most common best practices include:

- Implementing a robust inventory management system: This involves implementing a robust inventory management system that can track and monitor inventory levels, movements, and stock levels.

- Conducting regular inventory audits: This involves conducting regular inventory audits to ensure that inventory levels are accurate and up-to-date.

- Optimizing inventory levels: This involves optimizing inventory levels to minimize costs and maximize profitability.

- Implementing a just-in-time inventory management system: This involves implementing a just-in-time inventory management system to minimize inventory levels and reduce waste.

- Providing training to inventory management staff: This involves providing training to inventory management staff to ensure that they have the skills and knowledge needed to manage inventory effectively.

Common Inventory Management Mistakes

There are several common inventory management mistakes that businesses can make. Some of the most common mistakes include:- Overstocking: This involves holding too much inventory, which can result in waste and obsolescence.

- Understocking: This involves holding too little inventory, which can result in stockouts and lost sales.

- Poor inventory tracking and monitoring: This involves failing to track and monitor inventory levels, movements, and stock levels, which can result in inventory discrepancies and inaccuracies.

- Failure to optimize inventory levels: This involves failing to optimize inventory levels, which can result in wasted resources and reduced profitability.

- Lack of training for inventory management staff: This involves failing to provide training to inventory management staff, which can result in inventory management errors and inaccuracies.

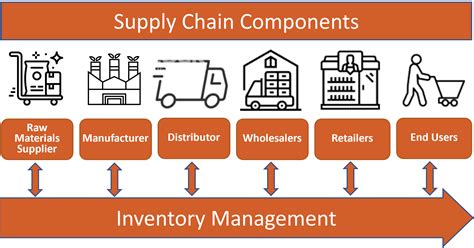

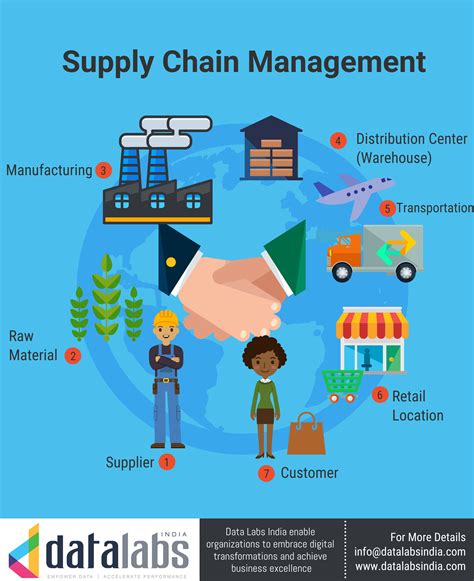

Inventory Management and Supply Chain Management

Inventory management and supply chain management are closely linked. Effective inventory management is critical to ensuring that products are available when customers need them, while supply chain management involves managing the flow of goods, products, or materials from raw materials to finished goods. Some of the key ways in which inventory management and supply chain management are linked include:

- Inventory planning and forecasting: This involves forecasting demand and planning inventory levels to meet customer demand.

- Inventory tracking and monitoring: This involves tracking and monitoring inventory levels, movements, and stock levels.

- Supply chain visibility: This involves having visibility into the supply chain to ensure that products are available when customers need them.

- Collaboration with suppliers: This involves collaborating with suppliers to ensure that products are available when customers need them.

- Inventory optimization: This involves optimizing inventory levels to minimize costs and maximize profitability.

Inventory Management and Technology

Inventory management and technology are closely linked. Technology can help businesses automate their inventory management processes, track and monitor inventory levels, and optimize their inventory levels to minimize costs and maximize profitability. Some of the key ways in which inventory management and technology are linked include:- Inventory management software: This involves using software to automate inventory management processes, track and monitor inventory levels, and optimize inventory levels.

- Barcode scanning and RFID: This involves using barcode scanning and RFID to track and monitor inventory levels, movements, and stock levels.

- Inventory reporting and analytics: This involves generating reports and analytics to help businesses optimize their inventory levels and minimize costs.

- Cloud-based inventory management: This involves using cloud-based inventory management systems to automate inventory management processes, track and monitor inventory levels, and optimize inventory levels.

- Artificial intelligence and machine learning: This involves using artificial intelligence and machine learning to optimize inventory levels, predict demand, and improve supply chain management.

Inventory Management and Customer Service

Inventory management and customer service are closely linked. Effective inventory management is critical to ensuring that products are available when customers need them, while customer service involves ensuring that customers are satisfied with the products and services they receive. Some of the key ways in which inventory management and customer service are linked include:

- Inventory availability: This involves ensuring that products are available when customers need them.

- Inventory tracking and monitoring: This involves tracking and monitoring inventory levels, movements, and stock levels to ensure that products are available when customers need them.

- Supply chain visibility: This involves having visibility into the supply chain to ensure that products are available when customers need them.

- Collaboration with suppliers: This involves collaborating with suppliers to ensure that products are available when customers need them.

- Inventory optimization: This involves optimizing inventory levels to minimize costs and maximize profitability, while also ensuring that products are available when customers need them.

Inventory Management and Financial Performance

Inventory management and financial performance are closely linked. Effective inventory management is critical to ensuring that businesses minimize their inventory costs, maximize their profitability, and improve their cash flow. Some of the key ways in which inventory management and financial performance are linked include:- Inventory costs: This involves minimizing inventory costs, such as storage, handling, and transportation costs.

- Inventory turnover: This involves maximizing inventory turnover, which involves selling and replacing inventory quickly to minimize inventory costs and maximize profitability.

- Cash flow: This involves improving cash flow, which involves managing inventory levels to minimize inventory costs and maximize profitability.

- Return on investment (ROI): This involves maximizing ROI, which involves optimizing inventory levels to minimize costs and maximize profitability.

- Financial reporting and analytics: This involves generating financial reports and analytics to help businesses optimize their inventory levels and minimize costs.

Inventory Management Image Gallery

What is inventory management?

+Inventory management refers to the process of planning, organizing, and controlling the flow of goods, products, or materials from raw materials to finished goods.

Why is inventory management important?

+Inventory management is important because it helps businesses minimize their inventory costs, maximize their profitability, and improve their cash flow.

What are the key components of an effective inventory management system?

+The key components of an effective inventory management system include inventory planning and forecasting, inventory tracking and monitoring, inventory control, inventory optimization, and supply chain management.

What are the benefits of effective inventory management?

+The benefits of effective inventory management include reduced inventory costs, improved cash flow, enhanced customer service, improved supply chain management, and reduced lead times.

How can businesses implement effective inventory management?

+Businesses can implement effective inventory management by implementing a robust inventory management system, conducting regular inventory audits, optimizing inventory levels, implementing a just-in-time inventory management system, and providing training to inventory management staff.

In conclusion, effective inventory management is critical to the success of any business. By implementing a robust inventory management system, conducting regular inventory audits, optimizing inventory levels, and providing training to inventory management staff, businesses can minimize their inventory costs, maximize their profitability, and improve their cash flow. We hope this article has provided you with a comprehensive understanding of the importance of inventory management and the key components of an effective inventory management system. If you have any further questions or would like to share your experiences with inventory management, please feel free to comment below.