Intro

Boost inventory management with 5 expert tracking tips, utilizing barcode scanning, stock monitoring, and automated reporting to optimize logistics and supply chain efficiency.

Effective inventory tracking is crucial for businesses to maintain a competitive edge in the market. It enables companies to manage their stock levels, reduce costs, and improve customer satisfaction. Inventory tracking involves monitoring the movement of goods, from procurement to delivery, to ensure that the right products are available at the right time. In this article, we will discuss the importance of inventory tracking and provide tips on how to implement an effective inventory tracking system.

Inventory tracking is essential for businesses to avoid stockouts, overstocking, and dead stock. Stockouts occur when a company runs out of a particular product, leading to lost sales and revenue. Overstocking, on the other hand, can result in wasted resources and increased storage costs. Dead stock refers to products that are no longer saleable or have become obsolete. By implementing an effective inventory tracking system, businesses can avoid these problems and ensure that they have the right products in stock to meet customer demand.

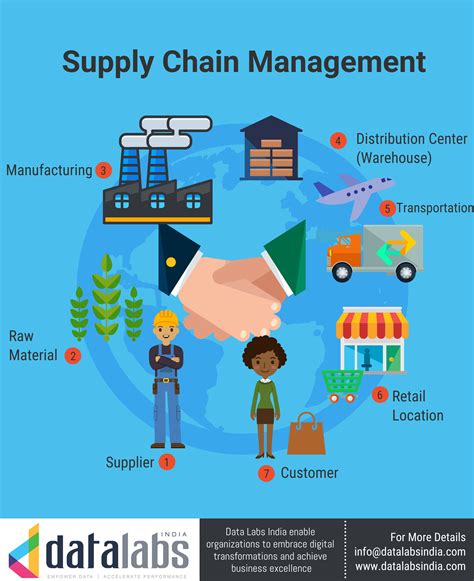

Inventory tracking also helps businesses to improve their supply chain management. By monitoring the movement of goods, companies can identify bottlenecks and inefficiencies in their supply chain and make necessary adjustments to improve delivery times and reduce costs. Additionally, inventory tracking enables businesses to track the performance of their suppliers and make informed decisions about future procurement.

Benefits of Inventory Tracking

Improved Stock Management

Inventory tracking enables businesses to manage their stock levels effectively. By monitoring the movement of goods, companies can identify trends and patterns in customer demand and adjust their stock levels accordingly. This helps to reduce the risk of stockouts and overstocking, ensuring that the right products are available at the right time.Reduced Costs

Inventory tracking can help businesses to reduce their costs in several ways. By avoiding stockouts and overstocking, companies can reduce their storage costs and minimize waste. Additionally, inventory tracking enables businesses to track the performance of their suppliers and negotiate better prices for their products.Inventory Tracking Tips

- Use Inventory Management Software: Inventory management software can help businesses to track their stock levels, monitor the movement of goods, and analyze sales trends. There are many different types of inventory management software available, ranging from basic spreadsheets to advanced cloud-based systems.

- Implement a Barcode Scanning System: Barcode scanning systems can help businesses to track the movement of goods quickly and accurately. By scanning barcodes on products, companies can update their inventory records in real-time, reducing the risk of errors and inaccuracies.

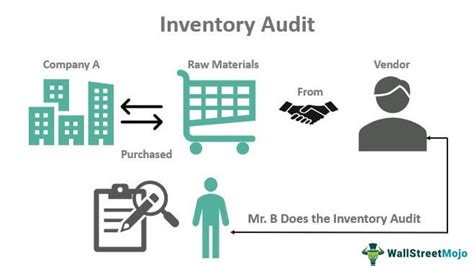

- Conduct Regular Inventory Audits: Regular inventory audits can help businesses to ensure that their inventory records are accurate and up-to-date. By conducting regular audits, companies can identify discrepancies and make necessary adjustments to their inventory records.

- Use Radio Frequency Identification (RFID) Technology: RFID technology can help businesses to track the movement of goods quickly and accurately. By using RFID tags on products, companies can update their inventory records in real-time, reducing the risk of errors and inaccuracies.

- Train Staff on Inventory Tracking Procedures: Inventory tracking is a team effort, and it's essential to train staff on inventory tracking procedures. By training staff on how to use inventory management software, barcode scanning systems, and RFID technology, businesses can ensure that their inventory tracking system is effective and efficient.

Best Practices for Inventory Tracking

In addition to the tips outlined above, there are several best practices that businesses can follow to ensure that their inventory tracking system is effective and efficient. Some of these best practices include:- Monitor Inventory Levels Regularly: Businesses should monitor their inventory levels regularly to ensure that they have the right products in stock to meet customer demand.

- Analyze Sales Trends: By analyzing sales trends, businesses can identify patterns and trends in customer demand and adjust their stock levels accordingly.

- Implement a Just-in-Time (JIT) Inventory System: A JIT inventory system can help businesses to reduce their inventory costs by ordering products just in time to meet customer demand.

Inventory Tracking Systems

- Manual Inventory Tracking Systems: Manual inventory tracking systems involve tracking inventory levels using a spreadsheet or other manual system.

- Barcode Scanning Systems: Barcode scanning systems involve using barcode scanners to track the movement of goods.

- RFID Inventory Tracking Systems: RFID inventory tracking systems involve using RFID tags to track the movement of goods.

- Cloud-Based Inventory Tracking Systems: Cloud-based inventory tracking systems involve using cloud-based software to track inventory levels and monitor the movement of goods.

Choosing the Right Inventory Tracking System

Choosing the right inventory tracking system can be a challenging task, especially for small businesses with limited resources. Some of the factors to consider when choosing an inventory tracking system include:- Cost: The cost of the inventory tracking system is an important consideration, especially for small businesses with limited budgets.

- Ease of Use: The ease of use of the inventory tracking system is also an important consideration, especially for businesses with limited technical expertise.

- Scalability: The scalability of the inventory tracking system is also an important consideration, especially for businesses that are growing rapidly.

Inventory Tracking and Supply Chain Management

- Improved Visibility: Inventory tracking can provide businesses with improved visibility into their supply chain, enabling them to track the movement of goods in real-time.

- Reduced Lead Times: Inventory tracking can help businesses to reduce their lead times by identifying bottlenecks and inefficiencies in their supply chain.

- Improved Supplier Performance: Inventory tracking can help businesses to improve supplier performance by tracking the performance of their suppliers and making informed decisions about future procurement.

Best Practices for Supply Chain Management

In addition to the tips outlined above, there are several best practices that businesses can follow to ensure that their supply chain management is effective and efficient. Some of these best practices include:- Monitor Supply Chain Performance Regularly: Businesses should monitor their supply chain performance regularly to identify bottlenecks and inefficiencies.

- Analyze Supply Chain Data: By analyzing supply chain data, businesses can identify trends and patterns in their supply chain and make informed decisions about future procurement.

- Implement a Supplier Scorecard: A supplier scorecard can help businesses to track the performance of their suppliers and make informed decisions about future procurement.

Conclusion and Final Thoughts

Final Thoughts

In final thoughts, inventory tracking is an ongoing process that requires continuous monitoring and improvement. By staying up-to-date with the latest trends and technologies in inventory tracking, businesses can stay ahead of the competition and achieve their goals. Some of the key takeaways from this article include the importance of using inventory management software, implementing a barcode scanning system, and conducting regular inventory audits.Inventory Tracking Image Gallery

What is inventory tracking?

+Inventory tracking is the process of monitoring the movement of goods, from procurement to delivery, to ensure that the right products are available at the right time.

Why is inventory tracking important?

+Inventory tracking is important because it enables businesses to manage their stock levels effectively, reduce costs, and improve customer satisfaction.

What are some common inventory tracking methods?

+Some common inventory tracking methods include manual inventory tracking, barcode scanning, and RFID inventory tracking.

How can inventory tracking improve supply chain management?

+Inventory tracking can improve supply chain management by providing businesses with improved visibility into their supply chain, enabling them to track the movement of goods in real-time.

What are some best practices for inventory tracking?

+Some best practices for inventory tracking include monitoring inventory levels regularly, analyzing sales trends, and implementing a just-in-time inventory system.

We hope that this article has provided you with a comprehensive overview of inventory tracking and its importance in business operations. If you have any questions or comments, please don't hesitate to reach out to us. We would be happy to hear from you and provide any additional information or guidance that you may need. Additionally, we encourage you to share this article with others who may be interested in learning more about inventory tracking and its benefits. By sharing this article, you can help to spread the word about the importance of inventory tracking and how it can help businesses to improve their operations and achieve their goals. Thank you for reading!