Intro

Boost inventory management with 5 expert tracking tips, utilizing barcode scanning, stock monitoring, and automated reporting to optimize logistics and supply chain efficiency.

Effective inventory management is crucial for businesses to maintain a competitive edge in the market. It involves tracking and controlling the flow of goods, products, or materials from procurement to delivery. One of the key components of inventory management is inventory tracking, which enables businesses to monitor their stock levels, reduce costs, and improve customer satisfaction. In this article, we will discuss the importance of inventory tracking and provide five valuable tips to help businesses optimize their inventory tracking processes.

Inventory tracking is essential for businesses to ensure that they have the right products in the right quantities at the right time. It helps businesses to avoid stockouts, overstocking, and deadstock, which can lead to significant losses and damage to their reputation. By implementing effective inventory tracking systems, businesses can reduce their inventory costs, improve their supply chain efficiency, and enhance their customer service. With the rise of e-commerce and omnichannel retailing, inventory tracking has become more complex, and businesses need to adopt innovative solutions to stay ahead of the competition.

The benefits of inventory tracking are numerous, and businesses that implement effective inventory tracking systems can experience significant improvements in their operations. Some of the benefits of inventory tracking include improved inventory accuracy, reduced stockouts and overstocking, enhanced supply chain visibility, and better decision-making. By tracking their inventory levels, businesses can identify trends and patterns, anticipate demand, and make informed decisions about their inventory management. In addition, inventory tracking can help businesses to reduce their inventory costs, improve their cash flow, and increase their profitability.

Understanding Inventory Tracking

Benefits of Inventory Tracking

The benefits of inventory tracking are numerous, and businesses that implement effective inventory tracking systems can experience significant improvements in their operations. Some of the benefits of inventory tracking include: * Improved inventory accuracy * Reduced stockouts and overstocking * Enhanced supply chain visibility * Better decision-making * Reduced inventory costs * Improved cash flow * Increased profitabilityTip 1: Implement a Cloud-Based Inventory Management System

Features of Cloud-Based Inventory Management Systems

Cloud-based inventory management systems offer a range of features that enable businesses to optimize their inventory tracking processes. Some of the key features of cloud-based systems include: * Real-time inventory tracking * Automated reporting and analytics * Scalability and flexibility * Access to inventory data from anywhere, at any time * Integration with e-commerce platforms and other business systems * Automated alerts and notificationsTip 2: Use Barcode Scanning and RFID Technology

Benefits of Barcode Scanning and RFID Technology

The benefits of barcode scanning and RFID technology are numerous, and businesses that implement these technologies can experience significant improvements in their inventory tracking processes. Some of the benefits of barcode scanning and RFID technology include: * Improved inventory accuracy * Automated data entry * Real-time visibility into inventory levels * Enhanced supply chain visibility * Better decision-making * Reduced inventory costsTip 3: Implement a Just-in-Time (JIT) Inventory System

Benefits of JIT Inventory Systems

The benefits of JIT inventory systems are numerous, and businesses that implement these systems can experience significant improvements in their operations. Some of the benefits of JIT inventory systems include: * Reduced inventory levels * Minimized waste * Improved cash flow * Enhanced supply chain visibility * Better decision-making * Increased profitabilityTip 4: Use Data Analytics to Optimize Inventory Tracking

Benefits of Data Analytics for Inventory Tracking

The benefits of data analytics for inventory tracking are numerous, and businesses that implement data analytics can experience significant improvements in their operations. Some of the benefits of data analytics for inventory tracking include: * Improved inventory accuracy * Reduced waste * Enhanced supply chain visibility * Better decision-making * Increased profitability * Real-time visibility into inventory levelsTip 5: Implement a Cycle Counting Program

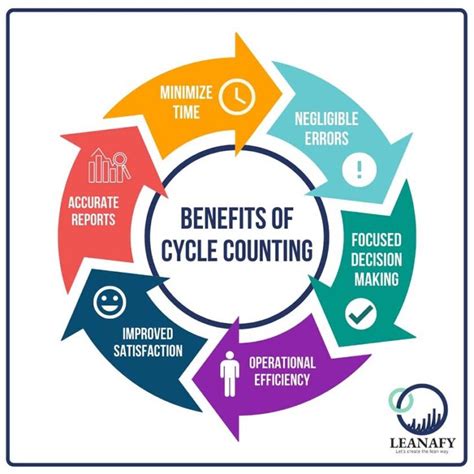

Benefits of Cycle Counting Programs

The benefits of cycle counting programs are numerous, and businesses that implement these programs can experience significant improvements in their operations. Some of the benefits of cycle counting programs include: * Improved inventory accuracy * Reduced waste * Enhanced supply chain visibility * Better decision-making * Increased profitability * Real-time visibility into inventory levelsGallery of Inventory Tracking Images

Inventory Tracking Image Gallery

What is inventory tracking?

+Inventory tracking is the process of monitoring and controlling inventory levels to ensure that businesses have the right products in the right quantities at the right time.

Why is inventory tracking important?

+Inventory tracking is important because it enables businesses to reduce waste, improve their supply chain efficiency, and enhance their customer service.

What are the benefits of inventory tracking?

+The benefits of inventory tracking include improved inventory accuracy, reduced waste, enhanced supply chain visibility, better decision-making, and increased profitability.

How can businesses implement effective inventory tracking systems?

+Businesses can implement effective inventory tracking systems by using cloud-based inventory management software, barcode scanning and RFID technology, just-in-time inventory systems, data analytics, and cycle counting programs.

What is the future of inventory tracking?

+The future of inventory tracking involves the use of emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) to improve inventory accuracy, reduce waste, and enhance supply chain efficiency.

In conclusion, inventory tracking is a critical component of inventory management that enables businesses to monitor and control their inventory levels, reduce waste, and improve their supply chain efficiency. By implementing effective inventory tracking systems, businesses can experience significant improvements in their operations, including improved inventory accuracy, reduced waste, and increased profitability. We hope that the tips and strategies outlined in this article will help businesses to optimize their inventory tracking processes and achieve their goals. If you have any questions or comments, please feel free to share them with us. We would love to hear from you and help you to improve your inventory tracking processes.