Intro

Boost efficiency with a inventory turnover calculator, optimizing stock levels and minimizing waste through effective inventory management, supply chain analysis, and demand forecasting techniques.

Inventory turnover is a crucial metric for businesses to measure their efficiency in managing inventory levels. It helps companies determine how quickly they sell and replace inventory, which can impact cash flow, profitability, and overall business performance. In this article, we will delve into the concept of inventory turnover, its importance, and provide a comprehensive guide on how to use an inventory turnover calculator to improve business operations.

The inventory turnover ratio is calculated by dividing the cost of goods sold by the average inventory level. This ratio provides insights into a company's ability to manage inventory, reduce waste, and optimize production. A high inventory turnover ratio indicates that a company is selling and replacing inventory quickly, which can lead to increased revenue and profitability. On the other hand, a low inventory turnover ratio may indicate overstocking, waste, or inefficient inventory management.

To calculate inventory turnover, businesses can use an inventory turnover calculator, which is a tool that simplifies the calculation process. The calculator typically requires inputting the cost of goods sold and the average inventory level, and then it provides the inventory turnover ratio. In the following sections, we will explore five ways to use an inventory turnover calculator to improve business operations.

Understanding Inventory Turnover Calculator

An inventory turnover calculator is a valuable tool for businesses to measure their inventory management efficiency. The calculator helps companies determine their inventory turnover ratio, which can be used to identify areas for improvement. By using an inventory turnover calculator, businesses can optimize their inventory levels, reduce waste, and improve cash flow.

Benefits of Using Inventory Turnover Calculator

The benefits of using an inventory turnover calculator include: * Improved inventory management: The calculator helps businesses optimize their inventory levels, reducing waste and overstocking. * Increased efficiency: By identifying areas for improvement, businesses can streamline their operations and reduce costs. * Enhanced decision-making: The inventory turnover ratio provides valuable insights into business performance, enabling informed decision-making. * Better cash flow management: By optimizing inventory levels, businesses can improve their cash flow and reduce the risk of inventory becoming obsolete.Calculating Inventory Turnover Ratio

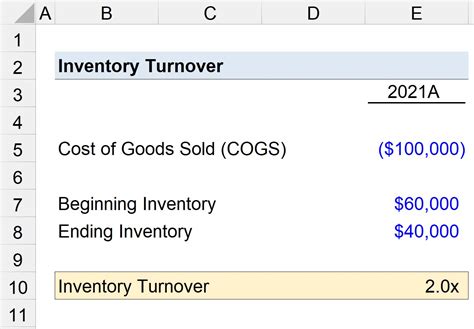

To calculate the inventory turnover ratio, businesses need to input the cost of goods sold and the average inventory level into the inventory turnover calculator. The formula for calculating inventory turnover is:

Inventory Turnover = Cost of Goods Sold / Average Inventory Level

For example, if the cost of goods sold is $100,000 and the average inventory level is $20,000, the inventory turnover ratio would be:

Inventory Turnover = $100,000 / $20,000 = 5

This means that the business sells and replaces its inventory five times per year.

Interpreting Inventory Turnover Ratio

The inventory turnover ratio can be interpreted in various ways, depending on the industry and business type. Generally, a high inventory turnover ratio indicates efficient inventory management, while a low ratio may indicate overstocking or waste. Here are some general guidelines for interpreting the inventory turnover ratio: * High ratio (above 5): Indicates efficient inventory management and high sales volume. * Medium ratio (between 3-5): Indicates average inventory management and moderate sales volume. * Low ratio (below 3): Indicates inefficient inventory management and low sales volume.Improving Inventory Turnover Ratio

To improve the inventory turnover ratio, businesses can implement various strategies, such as:

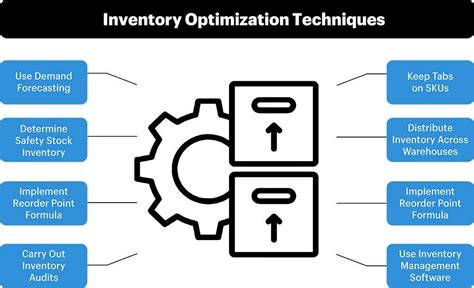

- Optimizing inventory levels: Reducing inventory levels can help improve the inventory turnover ratio.

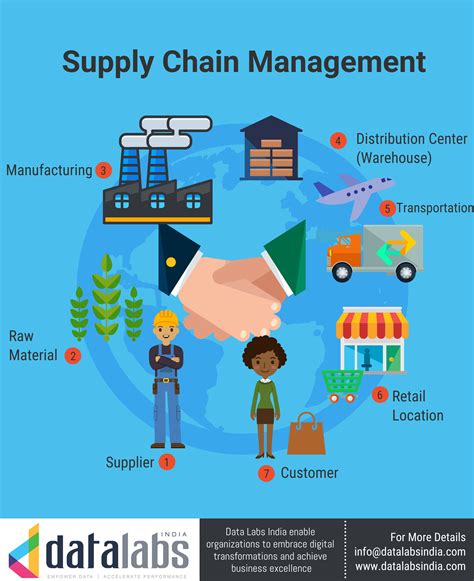

- Improving supply chain management: Streamlining the supply chain can help reduce lead times and improve inventory management.

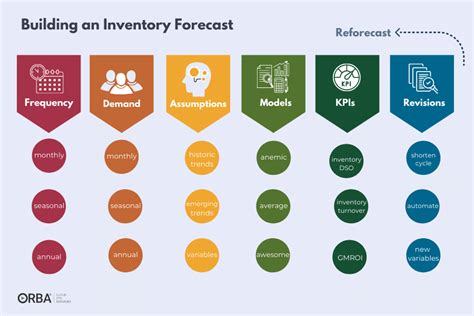

- Enhancing demand forecasting: Accurate demand forecasting can help businesses optimize inventory levels and reduce waste.

- Implementing just-in-time (JIT) production: JIT production can help reduce inventory levels and improve efficiency.

Best Practices for Inventory Management

Here are some best practices for inventory management: * Monitor inventory levels regularly: Regular monitoring can help identify areas for improvement and optimize inventory levels. * Implement a first-in, first-out (FIFO) system: FIFO can help reduce waste and improve inventory management. * Use inventory management software: Inventory management software can help streamline inventory management and improve efficiency. * Provide training for employees: Training employees on inventory management best practices can help improve overall efficiency.Inventory Turnover Calculator Tools

There are various inventory turnover calculator tools available, including:

- Spreadsheets: Spreadsheets can be used to calculate the inventory turnover ratio and provide insights into business performance.

- Inventory management software: Inventory management software can help streamline inventory management and provide real-time insights into inventory levels.

- Online calculators: Online calculators can provide a quick and easy way to calculate the inventory turnover ratio.

Choosing the Right Inventory Turnover Calculator

When choosing an inventory turnover calculator, businesses should consider the following factors: * Ease of use: The calculator should be easy to use and provide clear instructions. * Accuracy: The calculator should provide accurate results and take into account various factors that can impact the inventory turnover ratio. * Customization: The calculator should allow for customization to meet the specific needs of the business.Common Mistakes in Inventory Turnover Calculation

There are several common mistakes that businesses can make when calculating the inventory turnover ratio, including:

- Incorrect data: Using incorrect data can provide inaccurate results and impact business decisions.

- Failure to consider seasonal fluctuations: Seasonal fluctuations can impact inventory levels and the inventory turnover ratio.

- Not accounting for inventory obsolescence: Inventory obsolescence can impact the inventory turnover ratio and overall business performance.

Avoiding Common Mistakes

To avoid common mistakes, businesses should: * Use accurate data: Ensure that the data used to calculate the inventory turnover ratio is accurate and up-to-date. * Consider seasonal fluctuations: Take into account seasonal fluctuations when calculating the inventory turnover ratio. * Account for inventory obsolescence: Consider inventory obsolescence when calculating the inventory turnover ratio.Inventory Turnover Ratio Benchmarking

Benchmarking the inventory turnover ratio can help businesses compare their performance to industry averages and identify areas for improvement. Here are some industry averages for inventory turnover:

- Retail: 3-5

- Manufacturing: 5-7

- Wholesale: 4-6

Using Benchmarking to Improve Performance

By using benchmarking to compare their inventory turnover ratio to industry averages, businesses can: * Identify areas for improvement: Benchmarking can help identify areas where the business can improve its inventory management. * Set realistic goals: Benchmarking can help businesses set realistic goals for improving their inventory turnover ratio. * Monitor progress: Benchmarking can help businesses monitor their progress and make adjustments as needed.Inventory Turnover Image Gallery

What is inventory turnover ratio?

+The inventory turnover ratio is a metric that measures the number of times a company sells and replaces its inventory within a given period.

How do I calculate inventory turnover ratio?

+To calculate the inventory turnover ratio, divide the cost of goods sold by the average inventory level.

What is a good inventory turnover ratio?

+A good inventory turnover ratio varies by industry, but generally, a ratio above 5 indicates efficient inventory management.

How can I improve my inventory turnover ratio?

+To improve your inventory turnover ratio, optimize your inventory levels, improve supply chain management, and enhance demand forecasting.

What are the benefits of using an inventory turnover calculator?

+The benefits of using an inventory turnover calculator include improved inventory management, increased efficiency, and enhanced decision-making.

In conclusion, the inventory turnover calculator is a valuable tool for businesses to measure their inventory management efficiency. By understanding the concept of inventory turnover, calculating the inventory turnover ratio, and using an inventory turnover calculator, businesses can optimize their inventory levels, reduce waste, and improve cash flow. Remember to share your thoughts and experiences with inventory turnover calculation in the comments below, and don't forget to share this article with your colleagues and friends who may benefit from it.