Intro

Calculate inventory turns efficiently with our guide, covering turnover ratio, stock management, and asset optimization techniques.

The importance of inventory management cannot be overstated, especially for businesses that deal with physical products. One key metric that helps companies evaluate their inventory management efficiency is inventory turns. Inventory turns, also known as inventory turnover, is a ratio that shows how many times a company sells and replaces its inventory within a given period. This metric is crucial for businesses to determine if they are overstocking or understocking, which can significantly impact their bottom line. In this article, we will delve into the world of inventory turns calculation, its importance, and how it can be used to improve business operations.

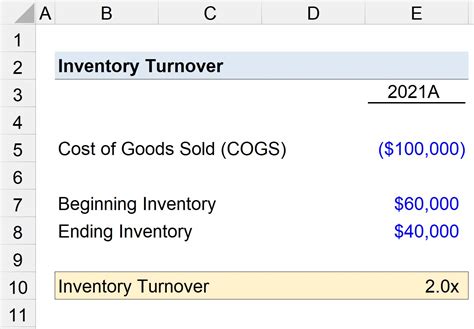

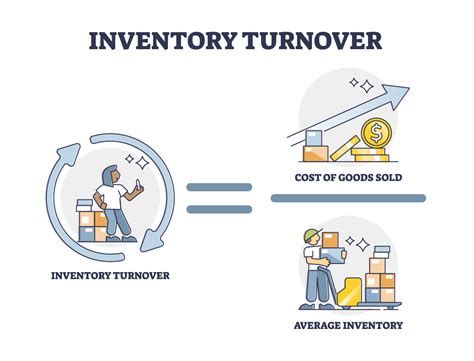

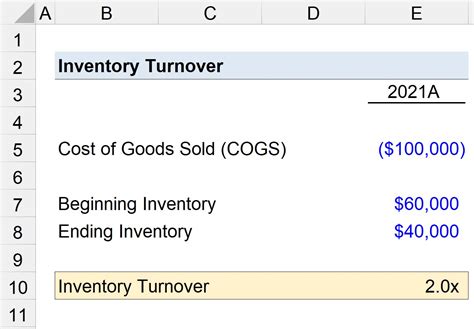

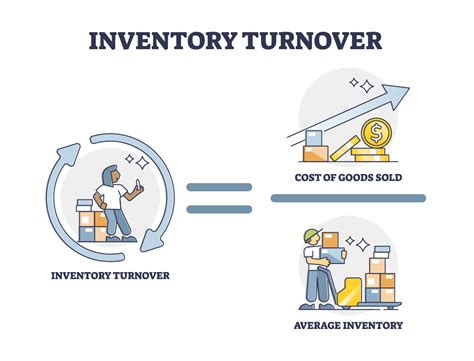

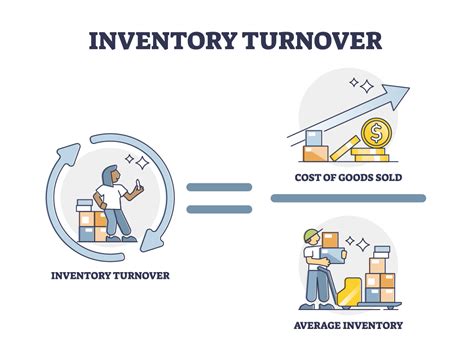

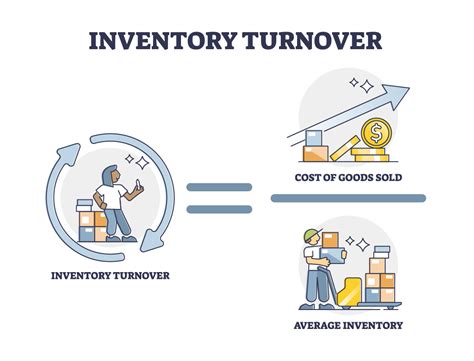

Inventory turns calculation is a straightforward process, but it requires accurate data and a clear understanding of the formula. The formula for calculating inventory turns is: Cost of Goods Sold (COGS) / Average Inventory. COGS represents the total cost of producing or purchasing the products sold by a company, while Average Inventory is the average value of inventory held by the company over a specific period. By dividing COGS by Average Inventory, businesses can determine how many times they have sold and replaced their inventory.

To better understand the importance of inventory turns, let's consider an example. Suppose a retail company has a COGS of $100,000 and an average inventory value of $20,000. Using the inventory turns formula, we can calculate the inventory turns as follows: $100,000 / $20,000 = 5. This means that the company sells and replaces its inventory five times within a given period. A high inventory turn indicates that a company is selling its products quickly and efficiently, while a low inventory turn suggests that the company may be holding too much inventory, which can lead to waste and unnecessary storage costs.

Understanding Inventory Turns

Understanding inventory turns is essential for businesses to make informed decisions about their inventory management strategies. A high inventory turn can indicate that a company is operating efficiently, with minimal waste and excess inventory. On the other hand, a low inventory turn can suggest that a company is holding too much inventory, which can lead to unnecessary storage costs, obsolescence, and waste. By analyzing inventory turns, businesses can identify areas for improvement and implement strategies to optimize their inventory management.

Benefits of Inventory Turns Analysis

The benefits of inventory turns analysis are numerous. By calculating and analyzing inventory turns, businesses can: * Identify overstocking and understocking issues * Optimize inventory levels to minimize waste and excess inventory * Improve cash flow by reducing inventory holding costs * Enhance customer satisfaction by ensuring that products are available when needed * Make informed decisions about inventory management strategiesCalculating Inventory Turns

Calculating inventory turns involves several steps. First, businesses need to determine their COGS, which represents the total cost of producing or purchasing the products sold. Next, they need to calculate their average inventory value over a specific period. This can be done by taking the average of the inventory values at the beginning and end of the period. Finally, businesses can calculate their inventory turns by dividing COGS by Average Inventory.

To illustrate the calculation process, let's consider an example. Suppose a company has a COGS of $50,000 and an average inventory value of $10,000. Using the inventory turns formula, we can calculate the inventory turns as follows: $50,000 / $10,000 = 5. This means that the company sells and replaces its inventory five times within a given period.

Inventory Turns Calculation Example

Here's an example of how to calculate inventory turns: * COGS: $100,000 * Average Inventory: $20,000 * Inventory Turns: $100,000 / $20,000 = 5Interpreting Inventory Turns Results

Interpreting inventory turns results is crucial for businesses to make informed decisions about their inventory management strategies. A high inventory turn indicates that a company is selling its products quickly and efficiently, while a low inventory turn suggests that the company may be holding too much inventory. By analyzing inventory turns results, businesses can identify areas for improvement and implement strategies to optimize their inventory management.

For example, a company with a high inventory turn may consider implementing a just-in-time (JIT) inventory system, which involves ordering and receiving inventory just in time to meet customer demand. On the other hand, a company with a low inventory turn may consider implementing a periodic review system, which involves reviewing inventory levels periodically to determine when to order more stock.

Inventory Turns Benchmarking

Benchmarking inventory turns involves comparing a company's inventory turns to industry averages or best practices. This can help businesses identify areas for improvement and implement strategies to optimize their inventory management. By benchmarking inventory turns, companies can: * Identify industry averages and best practices * Compare their inventory turns to industry averages * Implement strategies to improve inventory turnsImproving Inventory Turns

Improving inventory turns involves implementing strategies to optimize inventory management. Some common strategies include:

- Implementing a JIT inventory system

- Implementing a periodic review system

- Using inventory management software to track inventory levels and optimize ordering

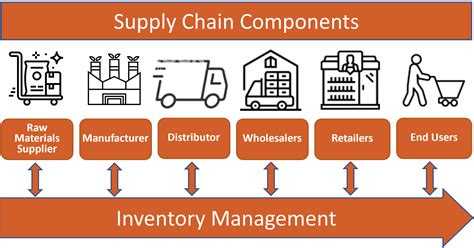

- Improving supply chain management to reduce lead times and improve delivery schedules

- Implementing a vendor-managed inventory (VMI) system, which involves allowing suppliers to manage inventory levels on behalf of the company

By implementing these strategies, businesses can improve their inventory turns, reduce waste and excess inventory, and enhance customer satisfaction.

Inventory Turns Best Practices

Here are some best practices for improving inventory turns: * Implement a JIT inventory system to reduce inventory holding costs * Use inventory management software to track inventory levels and optimize ordering * Improve supply chain management to reduce lead times and improve delivery schedules * Implement a VMI system to allow suppliers to manage inventory levels on behalf of the company * Regularly review inventory turns to identify areas for improvementInventory Turns and Cash Flow

Inventory turns have a significant impact on cash flow. By improving inventory turns, businesses can reduce inventory holding costs, which can free up cash for other uses. Additionally, improving inventory turns can enhance customer satisfaction, which can lead to increased sales and revenue.

To illustrate the impact of inventory turns on cash flow, let's consider an example. Suppose a company has an average inventory value of $100,000 and an inventory turn of 5. If the company improves its inventory turn to 10, it can reduce its average inventory value to $50,000, which can free up $50,000 in cash.

Inventory Turns and Customer Satisfaction

Inventory turns also have a significant impact on customer satisfaction. By improving inventory turns, businesses can ensure that products are available when needed, which can enhance customer satisfaction. Additionally, improving inventory turns can reduce lead times and improve delivery schedules, which can also enhance customer satisfaction.Inventory Turns and Supply Chain Management

Inventory turns are closely linked to supply chain management. By improving supply chain management, businesses can reduce lead times and improve delivery schedules, which can enhance inventory turns. Additionally, improving supply chain management can reduce inventory holding costs, which can also enhance inventory turns.

To illustrate the link between inventory turns and supply chain management, let's consider an example. Suppose a company has a supply chain that is prone to delays and disruptions. If the company improves its supply chain management, it can reduce lead times and improve delivery schedules, which can enhance inventory turns.

Inventory Turns and Inventory Management Software

Inventory management software can play a significant role in improving inventory turns. By using inventory management software, businesses can track inventory levels and optimize ordering, which can reduce inventory holding costs and enhance inventory turns. Additionally, inventory management software can provide real-time visibility into inventory levels, which can enable businesses to make informed decisions about inventory management.Inventory Turns Image Gallery

What is inventory turns?

+Inventory turns, also known as inventory turnover, is a ratio that shows how many times a company sells and replaces its inventory within a given period.

How is inventory turns calculated?

+Inventory turns is calculated by dividing the Cost of Goods Sold (COGS) by the Average Inventory.

Why is inventory turns important?

+Inventory turns is important because it helps businesses evaluate their inventory management efficiency and make informed decisions about their inventory management strategies.

How can inventory turns be improved?

+Inventory turns can be improved by implementing strategies such as just-in-time (JIT) inventory systems, periodic review systems, and using inventory management software to track inventory levels and optimize ordering.

What is the relationship between inventory turns and cash flow?

+Inventory turns has a significant impact on cash flow. By improving inventory turns, businesses can reduce inventory holding costs, which can free up cash for other uses.

In conclusion, inventory turns is a critical metric that helps businesses evaluate their inventory management efficiency. By calculating and analyzing inventory turns, companies can identify areas for improvement and implement strategies to optimize their inventory management. With the right strategies and tools, businesses can improve their inventory turns, reduce waste and excess inventory, and enhance customer satisfaction. We hope this guide has provided you with a comprehensive understanding of inventory turns calculation and its importance in business operations. If you have any further questions or would like to share your experiences with inventory turns, please feel free to comment below. Additionally, if you found this article helpful, please share it with your network to help others improve their inventory management skills.