Intro

Discover 5 ways to label and print efficiently, using labeling software, printers, and techniques, including barcode labeling, label templates, and wireless printing, to streamline your labeling process and improve organization.

The art of labeling and printing has become an essential aspect of various industries, including shipping, manufacturing, and retail. With the advancement of technology, labeling and printing have become more efficient, accurate, and cost-effective. In this article, we will explore the different ways to label and print, highlighting their benefits, working mechanisms, and practical applications.

Labeling and printing are crucial steps in the production and distribution process. They enable businesses to identify products, track inventory, and provide essential information to customers. The correct labeling and printing of products can make a significant difference in the supply chain, ensuring that goods are delivered to the right destination, and that customers receive accurate and reliable information. Moreover, labeling and printing can also enhance the aesthetic appeal of products, making them more attractive to customers and contributing to brand recognition.

The importance of labeling and printing cannot be overstated. In the shipping industry, for instance, accurate labeling ensures that packages are delivered to the correct address, while in the manufacturing sector, labeling helps to identify products and track inventory. In retail, labeling and printing are used to provide product information, prices, and promotions, making it easier for customers to make informed purchasing decisions. With the rise of e-commerce, labeling and printing have become even more critical, as online retailers rely on accurate labeling to ensure timely and efficient delivery of products.

Introduction to Labeling and Printing

Benefits of Labeling and Printing

The benefits of labeling and printing are numerous. They include: * Improved product identification and tracking * Enhanced customer experience through accurate and reliable information * Increased efficiency in the supply chain * Better inventory management * Improved brand recognition and aesthetic appeal * Compliance with regulatory requirements1. Thermal Transfer Labeling

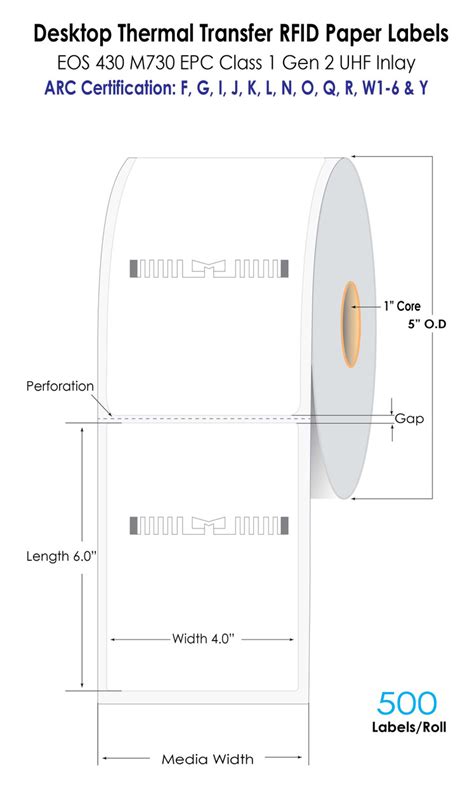

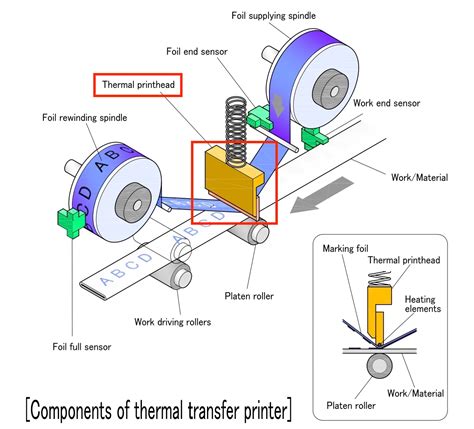

How Thermal Transfer Labeling Works

Thermal transfer labeling works by using a thermal print head to heat the ink on the ribbon, which is then transferred onto the label. The label is made of a special material that is designed to accept the ink, resulting in a high-quality print. The thermal transfer labeling process involves several steps, including: * Designing the label layout * Printing the label using a thermal transfer printer * Applying the label to the product or packaging2. Inkjet Labeling

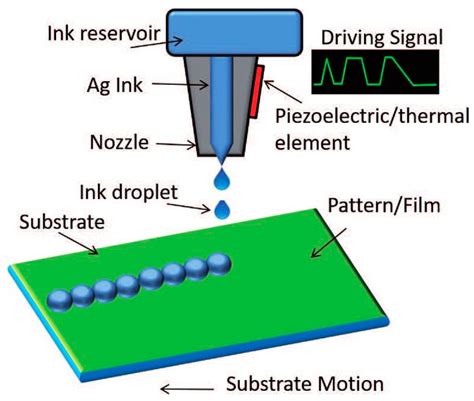

Benefits of Inkjet Labeling

Inkjet labeling offers several benefits, including: * High-quality prints with vibrant colors and precise text * Flexibility in terms of label size and shape * Cost-effectiveness compared to other labeling methods * Environmentally friendly, as it uses less ink and energy3. Laser Labeling

How Laser Labeling Works

Laser labeling works by using a laser to print labels. The laser prints the label by burning the ink onto the label material, resulting in a high-quality print. The laser labeling process involves several steps, including: * Designing the label layout * Printing the label using a laser printer * Applying the label to the product or packaging4. Digital Labeling

Benefits of Digital Labeling

Digital labeling offers several benefits, including: * High-quality prints with vibrant colors and precise text * Flexibility in terms of label size and shape * Cost-effectiveness compared to other labeling methods * Environmentally friendly, as it uses less ink and energy5. Flexographic Labeling

How Flexographic Labeling Works

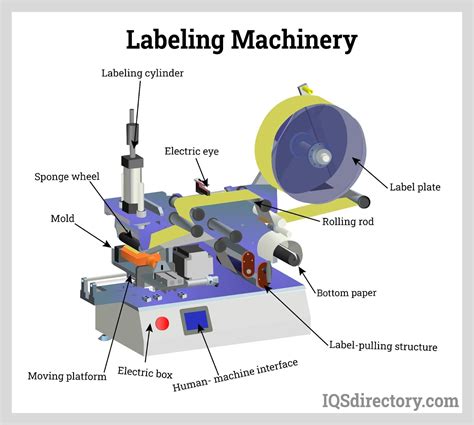

Flexographic labeling works by using a flexographic printing press to print labels. The flexographic printing press uses a flexible plate to print the label, resulting in a high-quality print. The flexographic labeling process involves several steps, including: * Designing the label layout * Printing the label using a flexographic printing press * Applying the label to the product or packagingLabeling and Printing Image Gallery

What is the difference between thermal transfer and inkjet labeling?

+Thermal transfer labeling uses heat to transfer ink from a ribbon onto a label, while inkjet labeling uses inkjet technology to print labels. Thermal transfer labeling is more durable and resistant to fading, while inkjet labeling is more flexible and cost-effective.

What are the benefits of digital labeling?

+Digital labeling offers several benefits, including high-quality prints, flexibility, and cost-effectiveness. It also allows for variable data printing, which enables businesses to print unique information on each label.

What is flexographic labeling, and how does it work?

+Flexographic labeling is a method of labeling that uses flexographic printing to print labels. It works by using a flexographic printing press to print labels, which uses a flexible plate to print the label. Flexographic labeling is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics.

In conclusion, labeling and printing are essential aspects of various industries, and there are several methods to choose from, each with its benefits and working mechanisms. By understanding the different labeling and printing methods, businesses can make informed decisions about which method to use, depending on their specific needs and requirements. Whether it's thermal transfer, inkjet, laser, digital, or flexographic labeling, each method has its unique advantages and disadvantages, and the right choice can make a significant difference in the production and distribution process. We hope this article has provided you with valuable insights into the world of labeling and printing, and we invite you to share your thoughts and experiences in the comments section below.