Intro

The use of barcode labels has become an essential part of various industries, including retail, manufacturing, and healthcare. These labels play a crucial role in inventory management, tracking, and identification of products. With the advancement of technology, barcode labels have evolved to become more efficient and effective. In this article, we will explore the importance of barcode labels and their applications in different fields.

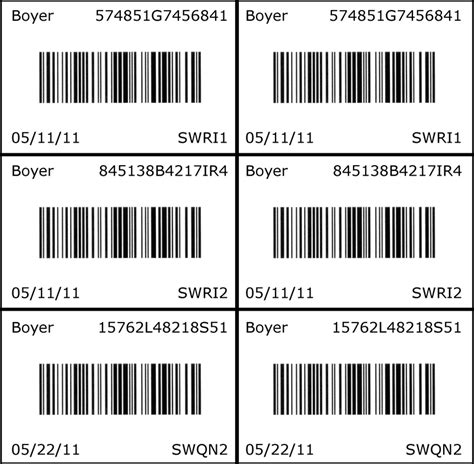

Barcode labels are used to store information about a product, such as its price, description, and serial number. This information can be easily accessed using a barcode scanner, which simplifies the process of inventory management and tracking. Additionally, barcode labels can be used to track the movement of products, from manufacturing to delivery, which helps to prevent losses and improve supply chain management.

The use of barcode labels has numerous benefits, including improved accuracy, increased efficiency, and reduced costs. By using barcode labels, businesses can automate many tasks, such as data entry and inventory tracking, which saves time and reduces the risk of human error. Furthermore, barcode labels can be used to provide customers with detailed information about products, such as ingredients, instructions, and warranty details.

Benefits of Using Barcode Labels

Improved Accuracy

Barcode labels can help to improve accuracy by reducing the risk of human error. When using barcode labels, data is automatically scanned and entered into a computer system, which eliminates the need for manual data entry. This reduces the risk of errors, such as typos and incorrect data entry, which can lead to inventory discrepancies and other problems.Increased Efficiency

Barcode labels can also help to increase efficiency by automating many tasks. For example, when using barcode labels, inventory tracking and management can be automated, which saves time and reduces the need for manual labor. Additionally, barcode labels can be used to track the movement of products, from manufacturing to delivery, which helps to prevent losses and improve supply chain management.Applications of Barcode Labels

- Inventory management and tracking

- Supply chain management

- Product identification and labeling

- Pricing and point-of-sale systems

- Healthcare and medical record keeping

Inventory Management and Tracking

Barcode labels are widely used in inventory management and tracking. By using barcode labels, businesses can automate the process of tracking inventory levels, which helps to prevent stockouts and overstocking. Additionally, barcode labels can be used to track the movement of products, from manufacturing to delivery, which helps to prevent losses and improve supply chain management.Supply Chain Management

Barcode labels can also be used in supply chain management to track the movement of products from one place to another. This helps to prevent losses and improve the efficiency of the supply chain. Additionally, barcode labels can be used to provide customers with detailed information about products, such as ingredients, instructions, and warranty details.Types of Barcode Labels

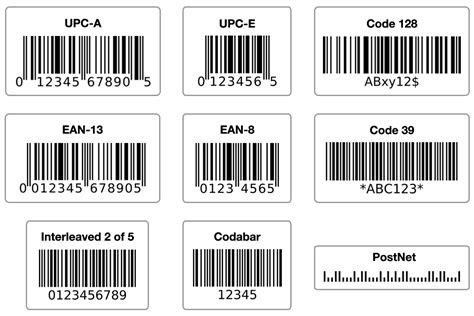

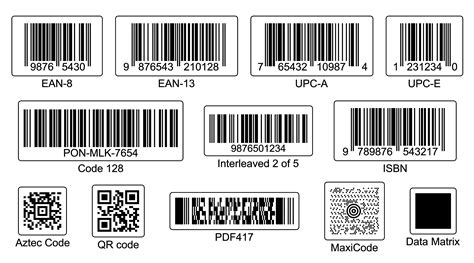

- Linear barcode labels

- 2D barcode labels

- QR code labels

- RFID labels

Linear Barcode Labels

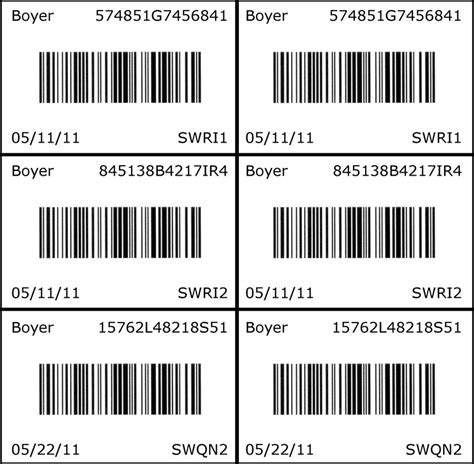

Linear barcode labels are the most common type of barcode label. They consist of a series of parallel lines and spaces that represent different characters. Linear barcode labels are widely used in inventory management and tracking, as well as in pricing and point-of-sale systems.2D Barcode Labels

2D barcode labels are more complex than linear barcode labels and can store more information. They consist of a series of squares and dots that represent different characters. 2D barcode labels are widely used in healthcare and medical record keeping, as well as in supply chain management.Best Practices for Using Barcode Labels

- Using high-quality barcode labels that are resistant to damage and wear

- Ensuring that barcode labels are properly aligned and positioned on products

- Using barcode scanners that are compatible with the type of barcode label being used

- Regularly testing and maintaining barcode labels to ensure they are working correctly

Using High-Quality Barcode Labels

Using high-quality barcode labels is essential to ensure that they are resistant to damage and wear. High-quality barcode labels should be made from durable materials that can withstand harsh environments and handling. Additionally, high-quality barcode labels should be designed to be easy to read and scan, with clear and concise information.Ensuring Proper Alignment and Positioning

Ensuring that barcode labels are properly aligned and positioned on products is also essential. Barcode labels should be positioned in a way that makes them easy to scan, with minimal obstruction or interference. Additionally, barcode labels should be aligned properly to ensure that they can be read correctly by barcode scanners.Common Mistakes to Avoid When Using Barcode Labels

- Using low-quality barcode labels that are prone to damage and wear

- Failing to properly align and position barcode labels on products

- Using barcode scanners that are not compatible with the type of barcode label being used

- Failing to regularly test and maintain barcode labels to ensure they are working correctly

Using Low-Quality Barcode Labels

Using low-quality barcode labels is a common mistake that can lead to problems with inventory management and tracking. Low-quality barcode labels may be prone to damage and wear, which can make them difficult to read and scan. Additionally, low-quality barcode labels may not be designed to be easy to read and scan, with unclear or incomplete information.Failing to Properly Align and Position Barcode Labels

Failing to properly align and position barcode labels on products is another common mistake. Barcode labels should be positioned in a way that makes them easy to scan, with minimal obstruction or interference. Additionally, barcode labels should be aligned properly to ensure that they can be read correctly by barcode scanners.Barcode Labels Image Gallery

What are the benefits of using barcode labels?

+The benefits of using barcode labels include improved accuracy, increased efficiency, and reduced costs. Barcode labels can help to automate many tasks, such as data entry and inventory tracking, which saves time and reduces the risk of human error.

What are the different types of barcode labels?

+There are several types of barcode labels, including linear barcode labels, 2D barcode labels, QR code labels, and RFID labels. Each type of barcode label has its own unique characteristics and applications.

How do I choose the right barcode label for my business?

+To choose the right barcode label for your business, you should consider the specific needs of your application. This includes the type of product being labeled, the environment in which the label will be used, and the type of scanner being used to read the label.

Can barcode labels be used for inventory management and tracking?

+Yes, barcode labels can be used for inventory management and tracking. By using barcode labels, businesses can automate the process of tracking inventory levels, which helps to prevent stockouts and overstocking.

Can barcode labels be used for supply chain management?

+Yes, barcode labels can be used for supply chain management. By using barcode labels, businesses can track the movement of products from one place to another, which helps to prevent losses and improve the efficiency of the supply chain.

In conclusion, barcode labels are a powerful tool for businesses looking to improve their inventory management and tracking, supply chain management, and product identification. By understanding the benefits and applications of barcode labels, businesses can make informed decisions about how to use them to improve their operations. Whether you're looking to automate tasks, improve accuracy, or increase efficiency, barcode labels are a great place to start. So why not start exploring the world of barcode labels today and see how they can help your business thrive? We invite you to comment below and share your experiences with barcode labels, and don't forget to share this article with others who may be interested in learning more about this topic.