Intro

Enhance warehouse safety with 7 essential forklift safety checks, including pre-operational inspections, operator training, and regular maintenance to prevent accidents and ensure a secure working environment.

Regular forklift safety checks are crucial to prevent accidents and ensure a safe working environment. Forklifts are powerful machines that can cause serious injuries or even fatalities if not operated and maintained properly. In this article, we will discuss the importance of forklift safety checks and provide a comprehensive guide on how to perform them.

Forklift safety checks are essential to identify potential hazards and prevent accidents. These checks help to ensure that the forklift is in good working condition, and all safety features are functioning properly. Regular safety checks also help to prevent equipment breakdowns, reduce maintenance costs, and improve overall productivity. Moreover, forklift safety checks are a regulatory requirement in many countries, and employers must ensure that their employees are trained to perform these checks.

The importance of forklift safety checks cannot be overstated. According to the Occupational Safety and Health Administration (OSHA), forklifts are responsible for approximately 85 deaths and 34,900 serious injuries each year in the United States. Many of these accidents could have been prevented if regular safety checks had been performed. Employers must take forklift safety seriously and ensure that their employees are trained to operate and maintain these machines safely.

Introduction to Forklift Safety Checks

Forklift safety checks are a critical component of a comprehensive safety program. These checks help to identify potential hazards and prevent accidents. Regular safety checks also help to ensure that the forklift is in good working condition, and all safety features are functioning properly. In this section, we will discuss the importance of forklift safety checks and provide a comprehensive guide on how to perform them.

Benefits of Forklift Safety Checks

The benefits of forklift safety checks are numerous. Some of the most significant benefits include: * Improved safety: Regular safety checks help to identify potential hazards and prevent accidents. * Reduced maintenance costs: Regular safety checks help to identify equipment problems early, reducing maintenance costs and downtime. * Improved productivity: Regular safety checks help to ensure that the forklift is in good working condition, improving productivity and efficiency. * Compliance with regulations: Forklift safety checks are a regulatory requirement in many countries, and employers must ensure that their employees are trained to perform these checks.Pre-Operational Checks

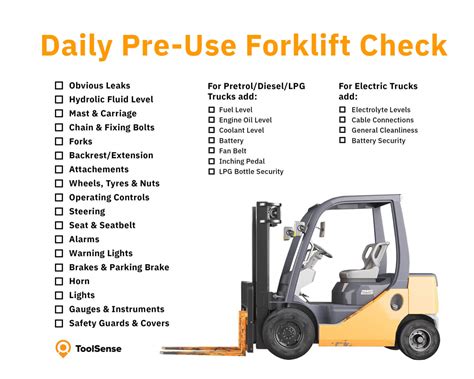

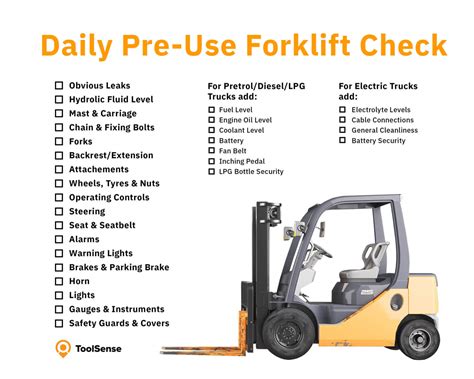

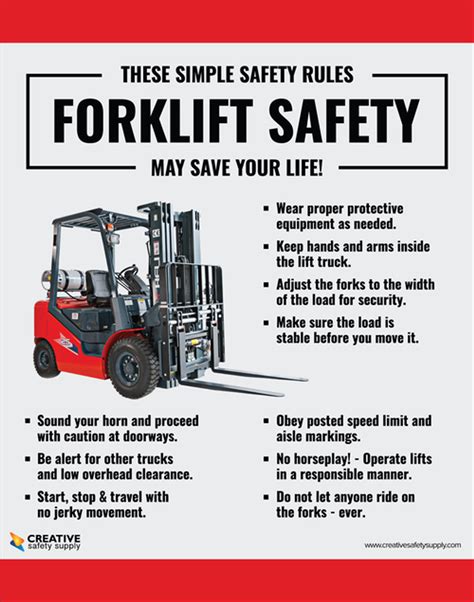

Pre-operational checks are an essential part of forklift safety checks. These checks are performed before the forklift is operated, and they help to ensure that the machine is in good working condition. Some of the key things to check during pre-operational checks include:

- The condition of the tires: Check for wear, damage, and proper inflation.

- The condition of the brakes: Check for proper function and wear.

- The condition of the steering: Check for proper function and wear.

- The condition of the hydraulic system: Check for leaks, damage, and proper function.

- The condition of the safety features: Check that all safety features, such as the horn, lights, and backup alarm, are functioning properly.

Steps to Perform Pre-Operational Checks

Performing pre-operational checks is a straightforward process. Here are the steps to follow: 1. Start by checking the condition of the tires. Look for wear, damage, and proper inflation. 2. Next, check the condition of the brakes. Make sure they are functioning properly and show no signs of wear. 3. Then, check the condition of the steering. Make sure it is functioning properly and shows no signs of wear. 4. After that, check the condition of the hydraulic system. Look for leaks, damage, and proper function. 5. Finally, check the condition of the safety features. Make sure all safety features, such as the horn, lights, and backup alarm, are functioning properly.Operational Checks

Operational checks are performed while the forklift is in operation. These checks help to ensure that the machine is functioning properly and safely. Some of the key things to check during operational checks include:

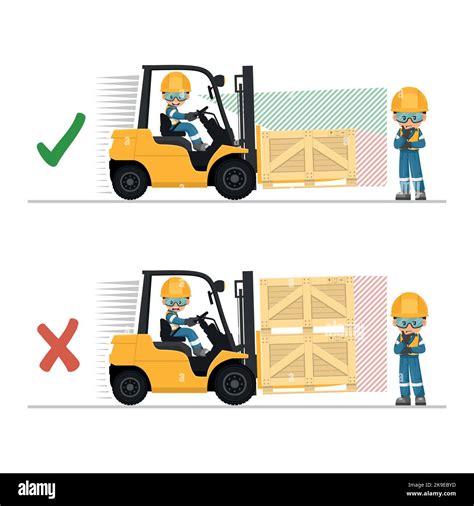

- The condition of the load: Check that the load is properly secured and within the forklift's capacity.

- The condition of the environment: Check for hazards, such as uneven surfaces, obstacles, and pedestrian traffic.

- The condition of the forklift: Check for proper function, wear, and damage.

Steps to Perform Operational Checks

Performing operational checks is a straightforward process. Here are the steps to follow: 1. Start by checking the condition of the load. Make sure it is properly secured and within the forklift's capacity. 2. Next, check the condition of the environment. Look for hazards, such as uneven surfaces, obstacles, and pedestrian traffic. 3. Then, check the condition of the forklift. Make sure it is functioning properly, and look for signs of wear and damage.Post-Operational Checks

Post-operational checks are performed after the forklift has been operated. These checks help to ensure that the machine is in good working condition and that any issues are identified and addressed. Some of the key things to check during post-operational checks include:

- The condition of the forklift: Check for proper function, wear, and damage.

- The condition of the environment: Check for hazards, such as uneven surfaces, obstacles, and pedestrian traffic.

- The condition of the load: Check that the load is properly secured and within the forklift's capacity.

Steps to Perform Post-Operational Checks

Performing post-operational checks is a straightforward process. Here are the steps to follow: 1. Start by checking the condition of the forklift. Make sure it is functioning properly, and look for signs of wear and damage. 2. Next, check the condition of the environment. Look for hazards, such as uneven surfaces, obstacles, and pedestrian traffic. 3. Then, check the condition of the load. Make sure it is properly secured and within the forklift's capacity.Regular Maintenance Checks

Regular maintenance checks are essential to ensure that the forklift is in good working condition. These checks help to identify potential issues before they become major problems. Some of the key things to check during regular maintenance checks include:

- The condition of the tires: Check for wear, damage, and proper inflation.

- The condition of the brakes: Check for proper function and wear.

- The condition of the steering: Check for proper function and wear.

- The condition of the hydraulic system: Check for leaks, damage, and proper function.

Steps to Perform Regular Maintenance Checks

Performing regular maintenance checks is a straightforward process. Here are the steps to follow: 1. Start by checking the condition of the tires. Look for wear, damage, and proper inflation. 2. Next, check the condition of the brakes. Make sure they are functioning properly and show no signs of wear. 3. Then, check the condition of the steering. Make sure it is functioning properly and shows no signs of wear. 4. After that, check the condition of the hydraulic system. Look for leaks, damage, and proper function.Training and Certification

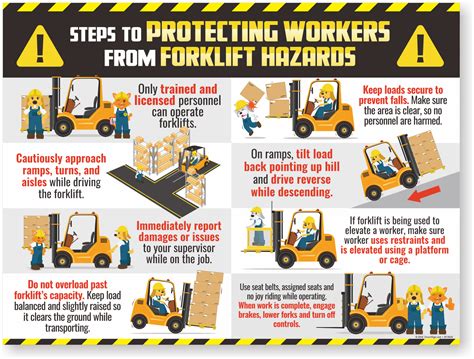

Training and certification are essential for forklift operators. These programs help to ensure that operators have the knowledge and skills necessary to operate the forklift safely and efficiently. Some of the key things to cover in a training and certification program include:

- The proper use of the forklift: Operators should be trained on the proper use of the forklift, including how to operate the machine, how to handle loads, and how to navigate the workplace.

- The importance of safety: Operators should be trained on the importance of safety, including how to identify hazards, how to prevent accidents, and how to respond to emergencies.

- The proper maintenance of the forklift: Operators should be trained on the proper maintenance of the forklift, including how to perform routine checks, how to identify issues, and how to report problems.

Steps to Implement a Training and Certification Program

Implementing a training and certification program is a straightforward process. Here are the steps to follow: 1. Start by developing a comprehensive training program that covers all aspects of forklift operation, safety, and maintenance. 2. Next, identify a qualified trainer who can deliver the training program. 3. Then, schedule the training program and ensure that all operators attend. 4. After that, evaluate the effectiveness of the training program and make any necessary adjustments.Gallery of Forklift Safety

Forklift Safety Image Gallery

Frequently Asked Questions

What is the importance of forklift safety checks?

+Forklift safety checks are crucial to prevent accidents and ensure a safe working environment. Regular safety checks help to identify potential hazards and prevent accidents.

How often should forklift safety checks be performed?

+Forklift safety checks should be performed regularly, including pre-operational, operational, and post-operational checks. Regular maintenance checks should also be performed to ensure the forklift is in good working condition.

What are the benefits of forklift safety checks?

+The benefits of forklift safety checks include improved safety, reduced maintenance costs, improved productivity, and compliance with regulations.

In conclusion, forklift safety checks are a critical component of a comprehensive safety program. Regular safety checks help to identify potential hazards and prevent accidents. By following the steps outlined in this article, employers can ensure that their employees are trained to perform forklift safety checks and that the forklift is in good working condition. We encourage readers to share their experiences and tips on forklift safety checks in the comments section below. Additionally, we invite readers to share this article with others who may benefit from the information. By working together, we can create a safer working environment for everyone.