Intro

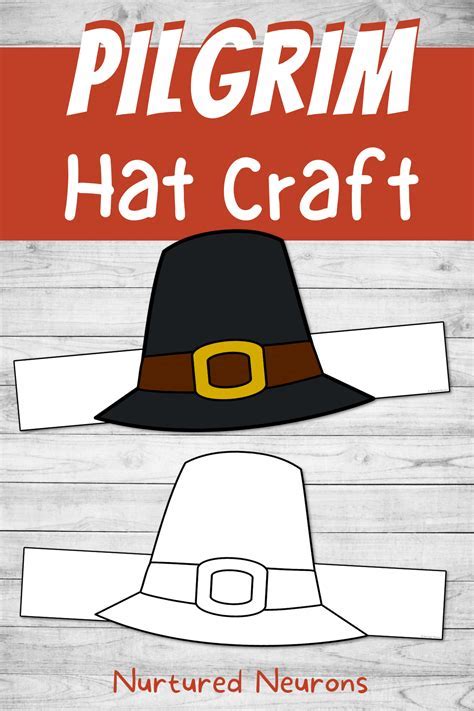

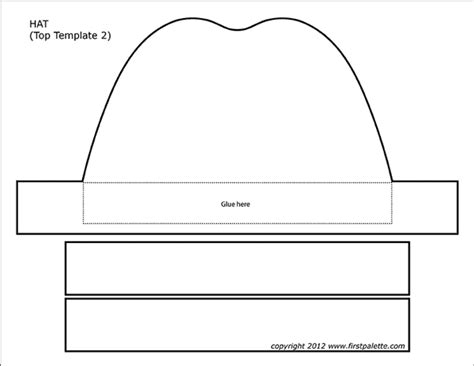

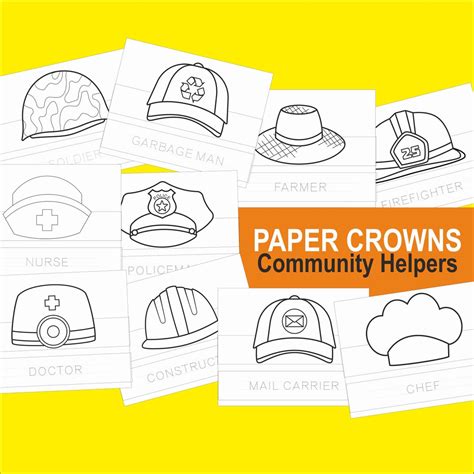

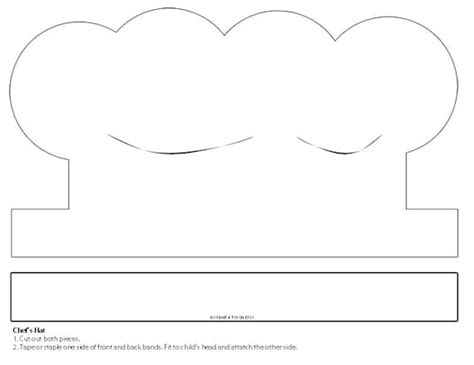

Discover customizable printable hat templates, perfect for DIY crafts and fashion accessories, featuring various hat styles, sizes, and designs to create unique headwear with paper hats, party hats, and more.

The world of fashion and technology has merged in recent years, giving birth to innovative and creative ideas. One such concept is the printable hat, which has taken the world of fashion by storm. With the advancement of 3D printing technology, it is now possible to create custom hats with intricate designs and patterns. In this article, we will delve into the world of printable hats, exploring their benefits, working mechanisms, and the steps involved in creating them.

The concept of printable hats is not just limited to fashion; it also has a significant impact on the environment. Traditional hat manufacturing processes involve the use of non-biodegradable materials, such as plastic and synthetic fabrics, which contribute to pollution and waste. On the other hand, printable hats can be made from eco-friendly materials, such as recycled plastics and natural fibers, reducing the carbon footprint of the fashion industry. Moreover, printable hats can be customized to fit individual preferences, reducing the need for mass production and minimizing waste.

The process of creating a printable hat involves several steps. First, a design is created using computer-aided design (CAD) software or other 3D modeling tools. The design is then sent to a 3D printer, which prints the hat layer by layer using a variety of materials, such as plastics, metals, and ceramics. The printing process can take several hours or even days, depending on the complexity of the design and the type of material used. Once the hat is printed, it can be finished with various techniques, such as painting, coating, or embroidery, to give it a unique look and feel.

Benefits of Printable Hats

Some of the key benefits of printable hats include:

- Customization: Printable hats can be designed to fit individual preferences, allowing for a high level of customization.

- Sustainability: Printable hats can be made from eco-friendly materials, reducing the environmental impact of the fashion industry.

- Efficiency: Printable hats can be produced quickly and efficiently, reducing the time and cost associated with traditional manufacturing processes.

- Innovation: Printable hats offer a new and innovative way to create fashion products, allowing designers to push the boundaries of traditional design.

Working Mechanisms of Printable Hats

Some of the key working mechanisms of printable hats include:

- 3D printing technology: The 3D printing process involves the layer-by-layer creation of the hat using a variety of materials.

- CAD software: The CAD software is used to design the hat, allowing for a high level of precision and accuracy.

- Materials: The materials used in the printing process can vary depending on the desired look and feel of the hat, as well as the level of sustainability desired.

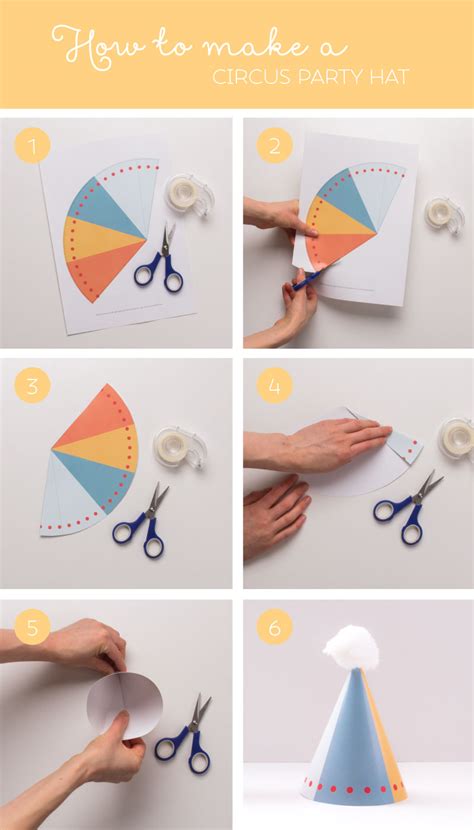

Steps Involved in Creating Printable Hats

Some of the key steps involved in creating printable hats include:

- Designing the hat: The design process involves creating a digital model of the hat using CAD software.

- Preparing the 3D printer: The 3D printer is prepared by loading the desired material and calibrating the printer.

- Printing the hat: The printing process involves the layer-by-layer creation of the hat using the 3D printer.

- Finishing the hat: The hat is finished with various techniques, such as painting, coating, or embroidery, to give it a unique look and feel.

Materials Used in Printable Hats

The materials used in printable hats can vary depending on the desired look and feel of the hat, as well as the level of sustainability desired. Some common materials used in printable hats include plastics, metals, and ceramics. Plastics are a popular choice for printable hats due to their durability and versatility. Metals, such as aluminum and steel, can be used to create hats with a more industrial look and feel. Ceramics, such as porcelain and ceramic composite materials, can be used to create hats with a more delicate and intricate design.Applications of Printable Hats

The applications of printable hats are numerous and varied. Printable hats can be used in a variety of settings, including fashion, art, and design. They can be used to create custom hats for individuals, or to produce hats on a larger scale for commercial purposes. Printable hats can also be used to create hats with unique and intricate designs, allowing designers to push the boundaries of traditional design.Future of Printable Hats

Some of the key trends that will shape the future of printable hats include:

- Advancements in 3D printing technology: As 3D printing technology continues to advance, we can expect to see even more innovative and creative designs.

- Increased use of sustainable materials: The use of sustainable and eco-friendly materials will become more prevalent, reducing the environmental impact of the fashion industry.

- Decrease in cost: The cost of 3D printing technology will decrease, making it more accessible to individuals and small businesses.

Challenges Facing the Printable Hat Industry

Some of the key challenges facing the printable hat industry include:

- High cost: The high cost of 3D printing technology can make it difficult for individuals and small businesses to access.

- Lack of standardization: The lack of standardization in the industry can make it difficult to ensure consistency and quality in the printing process.

- Environmental impact: The environmental impact of the printing process itself can be a concern, as it requires the use of energy and resources.

Conclusion and Final Thoughts

Printable Hat Image Gallery

What is a printable hat?

+A printable hat is a hat that is created using 3D printing technology. It can be customized to fit individual preferences and can be made from a variety of materials, including sustainable and eco-friendly options.

What are the benefits of printable hats?

+The benefits of printable hats include customization, sustainability, and efficiency. They can be made from eco-friendly materials, reducing the environmental impact of the fashion industry. Additionally, they can be produced quickly and efficiently, reducing the time and cost associated with traditional manufacturing processes.

What is the future of printable hats?

+The future of printable hats is exciting and full of possibilities. As 3D printing technology continues to advance, we can expect to see even more innovative and creative designs. The use of sustainable and eco-friendly materials will become more prevalent, reducing the environmental impact of the fashion industry. Additionally, the cost of 3D printing technology will decrease, making it more accessible to individuals and small businesses.

We hope this article has provided you with a comprehensive overview of the world of printable hats. Whether you are a fashion enthusiast, a designer, or simply someone interested in innovative technology, we encourage you to share your thoughts and opinions on the topic. Please feel free to comment below, share this article with your friends and family, or take specific actions to learn more about printable hats. Together, we can explore the exciting possibilities of this emerging field and create a more sustainable and innovative future for the fashion industry.