Intro

Discover custom printable heat transfers for DIY projects, featuring vibrant sublimation prints, heat press techniques, and transfer paper methods for fabric, ceramic, and metal applications.

The world of custom apparel and accessories has experienced a significant surge in recent years, with the demand for personalized products continuing to grow. One of the key technologies that have made this possible is printable heat transfers. These innovative transfers have revolutionized the way we create custom designs, logos, and images on various materials, including fabrics, plastics, and metals. In this article, we will delve into the world of printable heat transfers, exploring their benefits, working mechanisms, and applications.

Printable heat transfers have become an essential tool for businesses, individuals, and organizations looking to create custom products. They offer a cost-effective and efficient way to produce high-quality designs, logos, and images on various materials. The process of creating printable heat transfers involves printing the design onto a special paper or vinyl using a heat transfer printer. The printed design is then applied to the desired material using heat and pressure, resulting in a durable and long-lasting finish.

The importance of printable heat transfers cannot be overstated. They have opened up new avenues for creative expression, allowing individuals and businesses to showcase their unique personalities and brand identities. With the ability to create custom designs, logos, and images, printable heat transfers have become an essential tool for marketing, advertising, and promotional campaigns. Moreover, they have also enabled individuals to create personalized gifts, apparel, and accessories, making them a popular choice for special occasions and events.

Introduction to Printable Heat Transfers

Printable heat transfers are a type of heat transfer technology that uses a special paper or vinyl to print designs, logos, and images. The printed design is then applied to the desired material using heat and pressure, resulting in a durable and long-lasting finish. The process of creating printable heat transfers involves several steps, including designing, printing, and applying the transfer. With the advancement of technology, printable heat transfers have become more accessible and affordable, making them a popular choice for businesses, individuals, and organizations.

Benefits of Printable Heat Transfers

The benefits of printable heat transfers are numerous. They offer a cost-effective and efficient way to produce high-quality designs, logos, and images on various materials. Some of the key benefits of printable heat transfers include: * Cost-effectiveness: Printable heat transfers are a cost-effective way to produce custom designs, logos, and images. * Efficiency: The process of creating printable heat transfers is quick and efficient, making them ideal for large-scale production. * Durability: Printable heat transfers result in a durable and long-lasting finish, making them ideal for products that are subject to wear and tear. * Versatility: Printable heat transfers can be applied to a wide range of materials, including fabrics, plastics, and metals.How Printable Heat Transfers Work

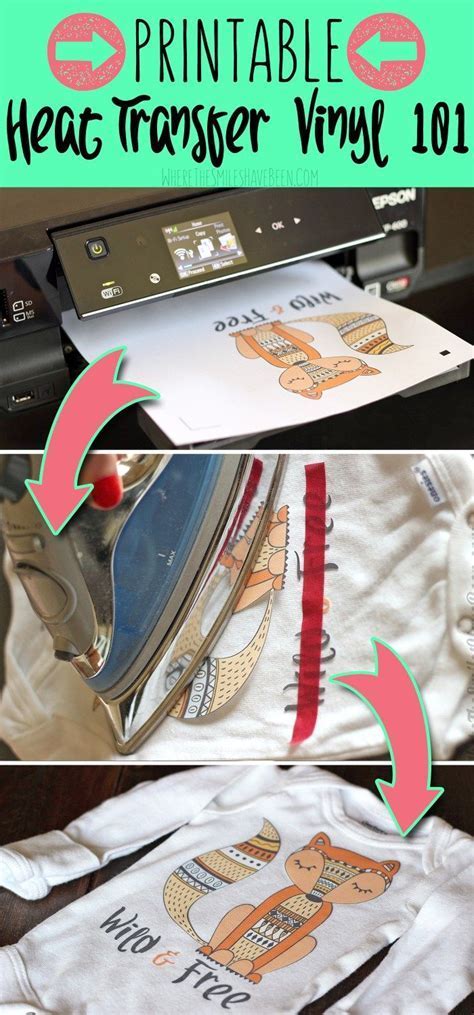

Printable heat transfers work by using a special paper or vinyl to print designs, logos, and images. The printed design is then applied to the desired material using heat and pressure, resulting in a durable and long-lasting finish. The process of creating printable heat transfers involves several steps, including:

- Designing: The design, logo, or image is created using a computer software or design program.

- Printing: The design is printed onto a special paper or vinyl using a heat transfer printer.

- Applying: The printed design is applied to the desired material using heat and pressure.

Types of Printable Heat Transfers

There are several types of printable heat transfers available, including: * Laser heat transfers: These transfers use a laser printer to print the design onto a special paper or vinyl. * Inkjet heat transfers: These transfers use an inkjet printer to print the design onto a special paper or vinyl. * Sublimation heat transfers: These transfers use a sublimation printer to print the design onto a special paper or vinyl.Applications of Printable Heat Transfers

Printable heat transfers have a wide range of applications, including:

- Custom apparel: Printable heat transfers are used to create custom designs, logos, and images on apparel, such as t-shirts, hoodies, and hats.

- Promotional products: Printable heat transfers are used to create custom designs, logos, and images on promotional products, such as mugs, water bottles, and keychains.

- Signs and displays: Printable heat transfers are used to create custom signs and displays for businesses, events, and exhibitions.

Tips and Tricks for Using Printable Heat Transfers

Here are some tips and tricks for using printable heat transfers: * Use high-quality paper or vinyl to ensure a durable and long-lasting finish. * Follow the instructions carefully when applying the transfer to the desired material. * Use a heat press to apply the transfer, as this will result in a more even and consistent finish.Common Mistakes to Avoid When Using Printable Heat Transfers

Here are some common mistakes to avoid when using printable heat transfers:

- Not following the instructions carefully when applying the transfer to the desired material.

- Using low-quality paper or vinyl, which can result in a poor finish.

- Not using a heat press to apply the transfer, which can result in an uneven and inconsistent finish.

Future of Printable Heat Transfers

The future of printable heat transfers looks bright, with advancements in technology and materials expected to improve the quality and efficiency of the process. Some of the trends that are expected to shape the future of printable heat transfers include: * Increased use of eco-friendly materials and processes. * Improved durability and longevity of the transfers. * Increased use of digital printing technologies, such as inkjet and laser printing.Gallery of Printable Heat Transfers

Printable Heat Transfers Image Gallery

Frequently Asked Questions

What are printable heat transfers?

+Printable heat transfers are a type of heat transfer technology that uses a special paper or vinyl to print designs, logos, and images.

How do printable heat transfers work?

+Printable heat transfers work by using a special paper or vinyl to print designs, logos, and images, which are then applied to the desired material using heat and pressure.

What are the benefits of using printable heat transfers?

+The benefits of using printable heat transfers include cost-effectiveness, efficiency, durability, and versatility.

What are the common mistakes to avoid when using printable heat transfers?

+The common mistakes to avoid when using printable heat transfers include not following the instructions carefully, using low-quality paper or vinyl, and not using a heat press to apply the transfer.

What is the future of printable heat transfers?

+The future of printable heat transfers looks bright, with advancements in technology and materials expected to improve the quality and efficiency of the process.

In conclusion, printable heat transfers have revolutionized the way we create custom designs, logos, and images on various materials. With their cost-effectiveness, efficiency, durability, and versatility, they have become an essential tool for businesses, individuals, and organizations. As technology continues to advance, we can expect to see even more innovative applications of printable heat transfers in the future. Whether you're looking to create custom apparel, promotional products, or signs and displays, printable heat transfers are an excellent choice. So why not give them a try and see the difference they can make for yourself? Share your experiences and thoughts on printable heat transfers in the comments below, and don't forget to share this article with others who may be interested in learning more about this exciting technology.