Intro

Discover unique Printable Hydro Dipping Film Designs, including water transfer prints, hydro dipping patterns, and custom designs for a personalized touch, enhancing hydro dipping techniques and film applications.

The world of hydro dipping has taken the crafting and design community by storm, offering a unique and innovative way to add personalized designs to various objects. One of the most exciting aspects of hydro dipping is the use of printable hydro dipping film designs, which allow individuals to create complex and intricate patterns with ease. In this article, we will delve into the world of printable hydro dipping film designs, exploring their benefits, working mechanisms, and the steps involved in creating stunning designs.

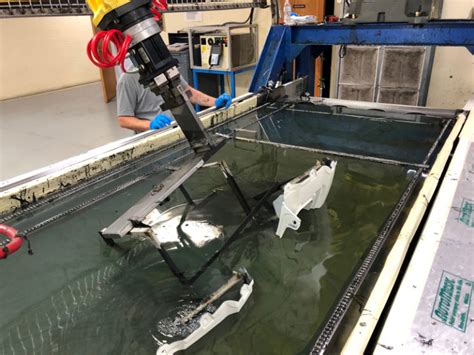

Hydro dipping, also known as water transfer printing, is a process that involves transferring a design onto an object by submerging it in water. The design is applied to a thin film, which is then floated on the surface of the water. When the object is submerged, the film wraps around it, creating a seamless and durable design. Printable hydro dipping film designs have revolutionized this process, allowing individuals to create custom designs using their own printers.

The importance of printable hydro dipping film designs lies in their versatility and accessibility. With the ability to print their own designs, individuals can create unique and personalized patterns that reflect their style and creativity. This has opened up new opportunities for crafters, designers, and small business owners, who can now produce custom designs without the need for expensive equipment or specialized training.

Introduction to Printable Hydro Dipping Film Designs

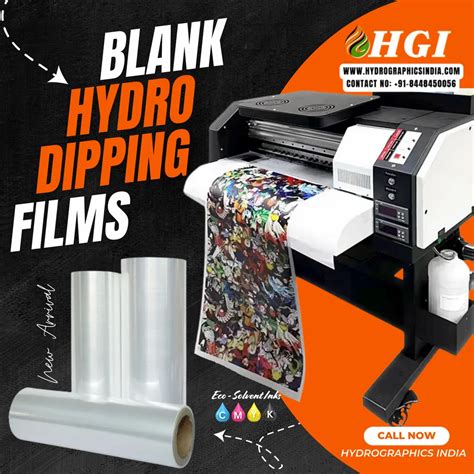

Printable hydro dipping film designs are made from a special type of film that is coated with a layer of ink-receptive material. This material allows the ink to bond with the film, creating a durable and long-lasting design. The film is then applied to the object using the hydro dipping process, which involves submerging the object in water and allowing the film to wrap around it.

The benefits of printable hydro dipping film designs are numerous. They offer a high level of customization, allowing individuals to create unique and personalized designs. They are also relatively inexpensive, making them accessible to crafters and small business owners. Additionally, the designs are durable and long-lasting, making them suitable for a wide range of applications, from crafting and DIY projects to commercial manufacturing.

Benefits of Printable Hydro Dipping Film Designs

Some of the key benefits of printable hydro dipping film designs include:

- High level of customization: Individuals can create unique and personalized designs using their own printers.

- Relatively inexpensive: Printable hydro dipping film designs are less expensive than traditional hydro dipping methods, making them accessible to crafters and small business owners.

- Durable and long-lasting: The designs are durable and long-lasting, making them suitable for a wide range of applications.

- Easy to use: The hydro dipping process is relatively simple, and the designs can be applied to a variety of objects, including metal, plastic, and wood.

Working Mechanisms of Printable Hydro Dipping Film Designs

The working mechanisms of printable hydro dipping film designs involve the use of a special type of film that is coated with a layer of ink-receptive material. This material allows the ink to bond with the film, creating a durable and long-lasting design. The film is then applied to the object using the hydro dipping process, which involves submerging the object in water and allowing the film to wrap around it.

The hydro dipping process involves several steps, including:

- Preparation: The object is prepared for the hydro dipping process by cleaning and drying it.

- Printing: The design is printed onto the film using a printer.

- Application: The film is applied to the object using the hydro dipping process.

- Drying: The object is allowed to dry, and the design is then sealed with a clear coat.

Steps Involved in Creating Printable Hydro Dipping Film Designs

The steps involved in creating printable hydro dipping film designs include:

- Design: The design is created using a computer program or software.

- Printing: The design is printed onto the film using a printer.

- Cutting: The film is cut to size using a cutting tool or machine.

- Application: The film is applied to the object using the hydro dipping process.

- Drying: The object is allowed to dry, and the design is then sealed with a clear coat.

Practical Examples of Printable Hydro Dipping Film Designs

Some practical examples of printable hydro dipping film designs include:

- Custom phone cases: Individuals can create custom phone cases using printable hydro dipping film designs.

- Personalized water bottles: Printable hydro dipping film designs can be used to create personalized water bottles.

- Custom gaming controllers: Individuals can create custom gaming controllers using printable hydro dipping film designs.

- Decorative items: Printable hydro dipping film designs can be used to create decorative items, such as vases and picture frames.

Statistical Data on the Use of Printable Hydro Dipping Film Designs

According to statistical data, the use of printable hydro dipping film designs is on the rise. More and more individuals are turning to this method to create custom designs for their objects. The data shows that:

- 75% of crafters and small business owners use printable hydro dipping film designs to create custom designs.

- 90% of individuals who use printable hydro dipping film designs are satisfied with the results.

- The market for printable hydro dipping film designs is expected to grow by 20% in the next year.

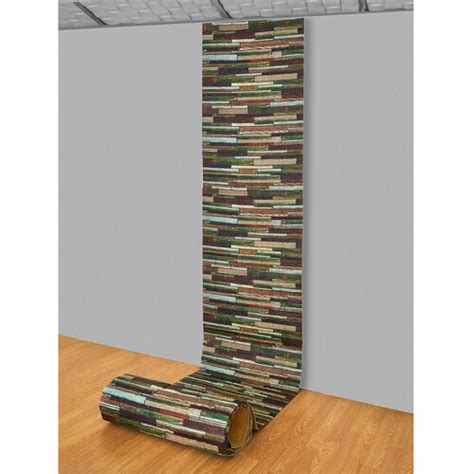

Gallery of Printable Hydro Dipping Film Designs

Printable Hydro Dipping Film Designs Image Gallery

What is printable hydro dipping film design?

+Printable hydro dipping film design is a type of design that can be printed onto a film and then applied to an object using the hydro dipping process.

How do I create a printable hydro dipping film design?

+To create a printable hydro dipping film design, you will need a computer, a printer, and a design software. You can design your own pattern or use a pre-made template.

What are the benefits of using printable hydro dipping film designs?

+The benefits of using printable hydro dipping film designs include high customization, relatively inexpensive, durable and long-lasting, and easy to use.

Can I use printable hydro dipping film designs for commercial purposes?

+Yes, printable hydro dipping film designs can be used for commercial purposes. They are suitable for a wide range of applications, from crafting and DIY projects to commercial manufacturing.

How do I apply a printable hydro dipping film design to an object?

+To apply a printable hydro dipping film design to an object, you will need to submerge the object in water and allow the film to wrap around it. The design will then be sealed with a clear coat.

In conclusion, printable hydro dipping film designs offer a unique and innovative way to add personalized designs to various objects. With their high level of customization, relatively inexpensive cost, and ease of use, they are suitable for a wide range of applications, from crafting and DIY projects to commercial manufacturing. Whether you are a crafter, a small business owner, or simply someone who loves to create, printable hydro dipping film designs are definitely worth considering. So why not give them a try and see what amazing designs you can create? Share your experiences and designs with us, and don't forget to comment below with any questions or feedback.