Intro

Discover 5 pipe saddle templates for efficient pipe fitting and welding. Explore saddle templates, pipe cutting, and fabrication techniques for precise pipe connections and joints.

The importance of pipe saddle templates cannot be overstated, especially in the context of industrial and engineering applications. Pipe saddles are crucial components used to support pipes, ensuring they are securely positioned and protected from damage. The design and fabrication of these saddles require precision and accuracy, which is where pipe saddle templates come into play. These templates serve as guides, enabling the creation of perfectly shaped saddles that fit snugly around pipes of various sizes. In this article, we will delve into the world of pipe saddle templates, exploring their significance, types, and applications, as well as providing insights into how they are used and fabricated.

Pipe saddle templates are essential tools in the fabrication of pipe saddles. They are used to ensure that the saddles are accurately shaped and sized to fit the specific pipes they are intended to support. Without these templates, the fabrication process would be highly prone to errors, leading to poorly fitting saddles that could compromise the integrity of the piping system. The use of pipe saddle templates streamlines the fabrication process, making it more efficient and cost-effective. Moreover, they help in maintaining consistency and quality across all fabricated saddles, which is critical in industries where safety and reliability are paramount.

The application of pipe saddle templates extends across various industries, including oil and gas, chemical processing, power generation, and construction. In these sectors, pipes are used extensively for the transportation of fluids and gases, and the support provided by pipe saddles is vital to prevent sagging, damage, and leakage. The templates are designed to accommodate pipes of different materials, such as steel, PVC, and copper, and can be customized to fit specific pipe sizes and configurations. This versatility makes pipe saddle templates indispensable tools for engineers, fabricators, and technicians working on piping projects.

Introduction to Pipe Saddle Templates

Pipe saddle templates are precision-made tools used in the fabrication of pipe saddles. They are designed to provide an accurate and consistent shape, ensuring that the saddles fit perfectly around the pipes. These templates can be made from various materials, including steel, aluminum, and plastic, depending on the intended application and the material of the pipes they will support. The choice of material for the template is crucial, as it must be durable enough to withstand repeated use without losing its shape or accuracy.

Types of Pipe Saddle Templates

There are several types of pipe saddle templates available, each designed to accommodate different pipe sizes, materials, and configurations. The most common types include: - Standard templates for common pipe sizes - Custom templates for specialized or non-standard pipe sizes - Adjustable templates that can be modified to fit various pipe diameters - Templates specifically designed for certain materials, such as PVC or steel pipesBenefits of Using Pipe Saddle Templates

The use of pipe saddle templates offers several benefits, including increased accuracy, improved efficiency, and enhanced safety. By ensuring that pipe saddles are fabricated to precise dimensions, these templates help prevent issues such as pipe sagging, leakage, and damage. This, in turn, reduces the risk of accidents and environmental hazards, making them an essential component in the fabrication process.

Some of the key benefits of using pipe saddle templates include:

- Accuracy and Precision: Ensures that pipe saddles are fabricated to exact specifications, reducing errors and the need for rework.

- Efficiency: Streamlines the fabrication process, allowing for the rapid production of high-quality pipe saddles.

- Safety: Contributes to the overall safety of piping systems by preventing potential hazards such as pipe failure and leakage.

- Cost-Effectiveness: Reduces waste and minimizes the need for costly repairs or replacements by ensuring that pipe saddles are correctly sized and fitted.

Applications of Pipe Saddle Templates

Pipe saddle templates find applications in a wide range of industries where piping systems are used. Some of the key sectors include: - Oil and Gas: For the transportation of petroleum products and natural gas. - Chemical Processing: To handle corrosive and hazardous chemicals. - Power Generation: In the construction of power plants and distribution systems. - Construction: For plumbing and HVAC systems in buildings.Design and Fabrication of Pipe Saddle Templates

The design and fabrication of pipe saddle templates involve several steps, from conceptualization to the final product. The process begins with determining the specific requirements of the project, including the type of pipe, its size, and the material from which the saddle will be made. This information is crucial for designing a template that will accurately guide the fabrication of the saddle.

The fabrication process itself can involve various techniques, depending on the material of the template and the available equipment. Common methods include CNC machining for metal templates and 3D printing for plastic or composite templates. The choice of fabrication method is influenced by factors such as the desired level of precision, the durability required, and the budget for the project.

Steps in Fabricating Pipe Saddle Templates

The fabrication of pipe saddle templates can be broken down into the following steps: 1. **Design**: Creating a detailed design of the template based on the specifications of the pipe and the requirements of the project. 2. **Material Selection**: Choosing the appropriate material for the template, considering factors such as durability, cost, and ease of fabrication. 3. **Fabrication**: Using the chosen method (e.g., CNC machining, 3D printing) to create the template. 4. **Testing and Validation**: Ensuring that the template meets the required specifications and can accurately guide the fabrication of pipe saddles.Best Practices for Using Pipe Saddle Templates

To maximize the benefits of pipe saddle templates, it is essential to follow best practices in their use and maintenance. This includes ensuring that the templates are stored properly to prevent damage, regularly inspecting them for wear and tear, and calibrating them as necessary to maintain their accuracy.

Some key best practices include:

- Regular Inspection: Periodically checking the templates for signs of wear or damage.

- Proper Storage: Storing templates in a dry, secure location to prevent accidental damage.

- Calibration: Regularly calibrating templates to ensure they remain accurate over time.

- Training: Ensuring that personnel using the templates are properly trained in their use and maintenance.

Maintenance and Calibration of Pipe Saddle Templates

Maintaining the accuracy and integrity of pipe saddle templates is crucial for ensuring the quality of the pipe saddles fabricated with them. This involves regular inspection for signs of wear, proper storage to prevent damage, and periodic calibration to ensure that the templates remain accurate over time.Gallery of Pipe Saddle Templates

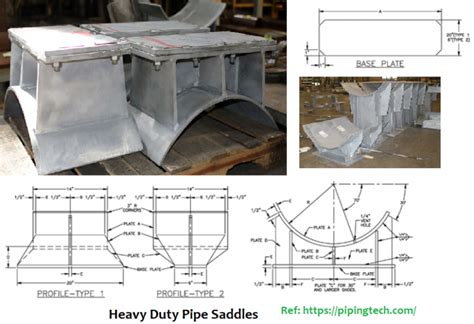

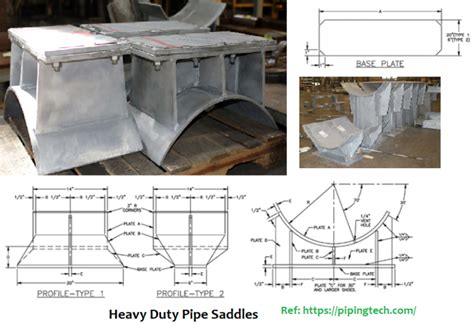

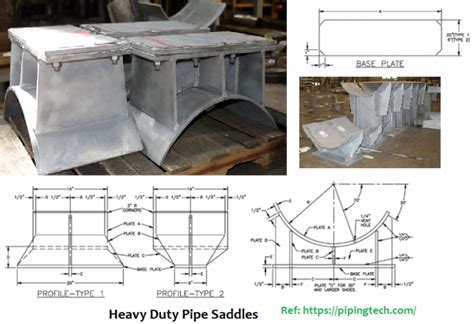

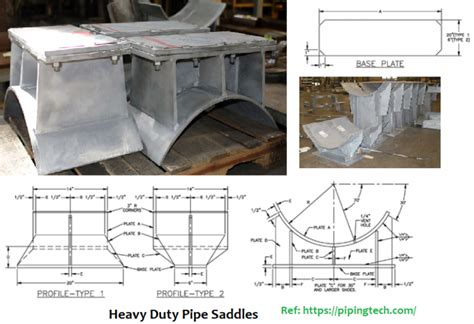

Pipe Saddle Templates Image Gallery

Frequently Asked Questions

What are pipe saddle templates used for?

+Pipe saddle templates are used to fabricate pipe saddles, which support pipes and prevent them from sagging or being damaged.

How are pipe saddle templates fabricated?

+Pipe saddle templates can be fabricated using various methods, including CNC machining and 3D printing, depending on the material and desired level of precision.

Why are pipe saddle templates important in piping systems?

+Pipe saddle templates are crucial because they ensure that pipe saddles are accurately sized and fitted, which is essential for the safety, efficiency, and reliability of piping systems.

Can pipe saddle templates be customized for specific pipe sizes and materials?

+How often should pipe saddle templates be inspected and calibrated?

+Pipe saddle templates should be regularly inspected for signs of wear and calibrated as necessary to ensure they remain accurate and effective.

In conclusion, pipe saddle templates play a vital role in the fabrication of pipe saddles, which are essential components of piping systems. Their accuracy, efficiency, and versatility make them indispensable tools in various industries. By understanding the importance, types, and applications of pipe saddle templates, as well as best practices for their use and maintenance, professionals can ensure the reliability and safety of piping systems. Whether you are involved in the oil and gas industry, chemical processing, power generation, or construction, recognizing the value of pipe saddle templates can significantly impact the quality and performance of your piping projects. We invite you to share your experiences, ask questions, or provide feedback on the use of pipe saddle templates in your industry, contributing to a community that values precision, safety, and innovation.