Intro

Discover innovative printable plastic solutions, including flexible materials, 3D printing, and eco-friendly options, for versatile applications in packaging, manufacturing, and design, offering durability and sustainability.

The world of plastics has undergone significant transformations over the years, with innovations aimed at making plastic products more sustainable, versatile, and environmentally friendly. One of the most exciting developments in this field is the concept of printable plastic solutions. This technology has opened up new avenues for manufacturing, design, and even sustainability. The importance of printable plastic solutions cannot be overstated, as they offer a wide range of benefits, from rapid prototyping and production to the creation of complex geometries that cannot be achieved with traditional manufacturing methods.

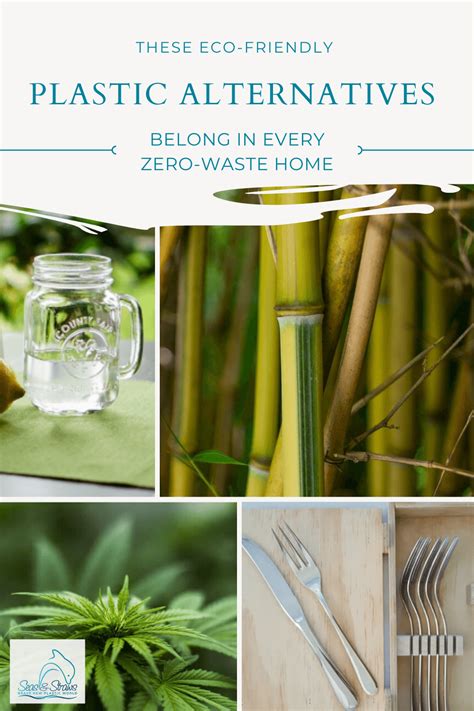

The versatility of printable plastic solutions is another key factor that has garnered significant attention. These solutions can be used across various industries, including healthcare, automotive, aerospace, and consumer products. The ability to print plastics with specific properties, such as flexibility, transparency, or conductivity, has expanded the possibilities for product design and development. Furthermore, the use of recyclable and biodegradable materials in printable plastic solutions is a significant step towards reducing plastic waste and promoting sustainability.

As the world grapples with the challenges of plastic pollution and waste management, printable plastic solutions offer a beacon of hope. By enabling the production of plastics with minimal waste, these solutions can help reduce the environmental footprint of manufacturing processes. Moreover, the use of printable plastic solutions can also facilitate the creation of products with improved durability and performance, which can lead to a reduction in the overall consumption of plastics.

Introduction to Printable Plastic Solutions

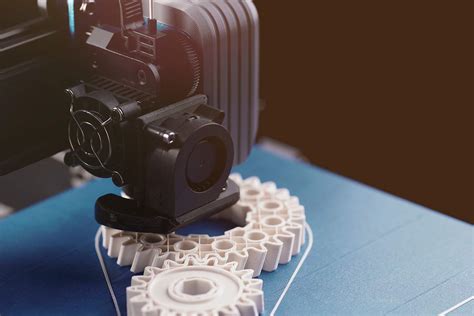

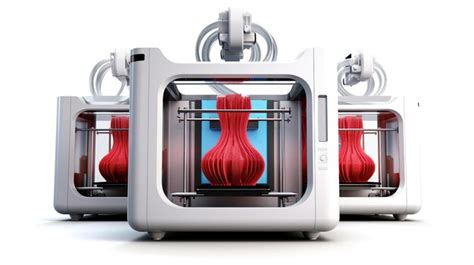

Printable plastic solutions refer to the use of additive manufacturing technologies, such as 3D printing, to create plastic products. This process involves the layer-by-layer deposition of plastic materials, which can be melted and fused together to form a solid product. The technology has advanced significantly over the years, with improvements in printer resolution, speed, and material compatibility. Today, printable plastic solutions can be used to create a wide range of products, from simple prototypes to complex production parts.

Benefits of Printable Plastic Solutions

The benefits of printable plastic solutions are numerous and significant. Some of the key advantages include: * Rapid prototyping and production: Printable plastic solutions enable the quick creation of prototypes and production parts, which can accelerate product development and reduce time-to-market. * Complex geometries: The additive manufacturing process used in printable plastic solutions allows for the creation of complex geometries and structures that cannot be achieved with traditional manufacturing methods. * Minimal waste: The layer-by-layer deposition process used in printable plastic solutions generates minimal waste, which can help reduce the environmental footprint of manufacturing processes. * Customization: Printable plastic solutions enable the creation of customized products with specific properties and geometries, which can be tailored to meet the needs of individual customers.Applications of Printable Plastic Solutions

Printable plastic solutions have a wide range of applications across various industries. Some of the key areas where these solutions are being used include:

- Healthcare: Printable plastic solutions are being used in the healthcare industry to create customized prosthetics, implants, and surgical models.

- Automotive: The automotive industry is using printable plastic solutions to create lightweight vehicle components, such as dashboard trim and engine parts.

- Aerospace: The aerospace industry is leveraging printable plastic solutions to create complex aircraft components, such as satellite parts and drone components.

- Consumer products: Printable plastic solutions are being used in the consumer products industry to create customized phone cases, toys, and household items.

Materials Used in Printable Plastic Solutions

The materials used in printable plastic solutions are diverse and varied. Some of the most common materials include: * PLA (polylactic acid): A biodegradable thermoplastic that is commonly used in 3D printing. * ABS (acrylonitrile butadiene styrene): A strong and impact-resistant thermoplastic that is widely used in 3D printing. * PETG (polyethylene terephthalate glycol): A strong and flexible thermoplastic that is commonly used in 3D printing. * Nylon: A strong and abrasion-resistant thermoplastic that is widely used in 3D printing.Challenges and Limitations of Printable Plastic Solutions

While printable plastic solutions offer a wide range of benefits and opportunities, there are also several challenges and limitations that need to be addressed. Some of the key challenges include:

- Cost: The cost of printable plastic solutions can be high, especially for large-scale production.

- Speed: The speed of printable plastic solutions can be slow, especially for complex geometries and large products.

- Material properties: The material properties of printable plastic solutions can be limited, especially when compared to traditional manufacturing methods.

- Scalability: The scalability of printable plastic solutions can be limited, especially for large-scale production.

Future Developments in Printable Plastic Solutions

The future of printable plastic solutions is exciting and promising. Some of the key developments that are expected to shape the industry include: * Advances in printer technology: Improvements in printer resolution, speed, and material compatibility are expected to enhance the capabilities of printable plastic solutions. * New materials: The development of new materials with improved properties and performance is expected to expand the possibilities for printable plastic solutions. * Increased adoption: The increased adoption of printable plastic solutions across various industries is expected to drive growth and innovation in the sector.Gallery of Printable Plastic Solutions

Printable Plastic Solutions Image Gallery

Frequently Asked Questions

What are printable plastic solutions?

+Printable plastic solutions refer to the use of additive manufacturing technologies, such as 3D printing, to create plastic products.

What are the benefits of printable plastic solutions?

+The benefits of printable plastic solutions include rapid prototyping and production, complex geometries, minimal waste, and customization.

What are the applications of printable plastic solutions?

+Printable plastic solutions have a wide range of applications across various industries, including healthcare, automotive, aerospace, and consumer products.

What are the challenges and limitations of printable plastic solutions?

+The challenges and limitations of printable plastic solutions include cost, speed, material properties, and scalability.

What is the future of printable plastic solutions?

+The future of printable plastic solutions is exciting and promising, with advances in printer technology, new materials, and increased adoption expected to drive growth and innovation in the sector.

In conclusion, printable plastic solutions offer a wide range of benefits and opportunities for innovation and growth. As the technology continues to evolve and improve, we can expect to see significant advancements in the field. Whether you are a business owner, entrepreneur, or simply someone interested in learning more about this exciting technology, we invite you to share your thoughts and experiences with us. Join the conversation and let's explore the possibilities of printable plastic solutions together!