Intro

The world of electronics and engineering is full of fascinating tools and techniques that help us create, repair, and maintain various devices and systems. One such tool that has gained popularity in recent years is shrink tubing, also known as heat shrink tubing. This versatile material has numerous applications, from insulation and protection to identification and organization. In this article, we will delve into the world of shrink tubing, exploring its benefits, types, and uses, as well as providing a comprehensive guide on how to use it effectively.

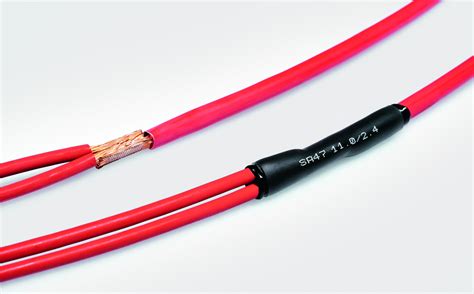

Shrink tubing is a type of plastic tubing that shrinks in size when exposed to heat, typically from a heat gun or a flame. This process, called heat shrinking, allows the tubing to fit snugly around objects, such as wires, cables, and connectors, providing a secure and reliable connection. The tubing is made from a variety of materials, including polyolefin, PVC, and Teflon, each with its own unique properties and advantages. Whether you're a professional engineer or a DIY enthusiast, shrink tubing is an essential tool to have in your arsenal.

Introduction to Shrink Tubing

Shrink tubing has been around for decades, but its popularity has grown significantly in recent years due to its ease of use, versatility, and effectiveness. The tubing is available in various sizes, colors, and materials, making it suitable for a wide range of applications. From simple tasks like insulating wires and cables to more complex projects like creating custom connectors and adapters, shrink tubing is an indispensable tool.

Benefits of Shrink Tubing

So, what makes shrink tubing so special? Here are some of the key benefits of using shrink tubing:

- Insulation and protection: Shrink tubing provides a secure and reliable way to insulate and protect wires, cables, and connectors from environmental factors like moisture, dust, and extreme temperatures.

- Identification and organization: Colored shrink tubing can be used to identify and organize cables, wires, and connectors, making it easier to manage complex systems and devices.

- Ease of use: Shrink tubing is relatively easy to use, even for those without extensive experience in electronics or engineering.

- Versatility: Shrink tubing is available in various sizes, colors, and materials, making it suitable for a wide range of applications.

Types of Shrink Tubing

There are several types of shrink tubing available, each with its own unique properties and advantages. Some of the most common types include:

- Polyolefin shrink tubing: This is one of the most popular types of shrink tubing, known for its flexibility, durability, and resistance to abrasion and chemicals.

- PVC shrink tubing: This type of tubing is known for its flexibility and resistance to moisture and abrasion.

- Teflon shrink tubing: This type of tubing is known for its high temperature resistance and non-stick properties.

Uses of Shrink Tubing

Shrink tubing has a wide range of applications, from simple tasks like insulating wires and cables to more complex projects like creating custom connectors and adapters. Some of the most common uses of shrink tubing include:

- Insulating and protecting wires and cables

- Creating custom connectors and adapters

- Identifying and organizing cables, wires, and connectors

- Protecting devices and systems from environmental factors like moisture, dust, and extreme temperatures

How to Use Shrink Tubing

Using shrink tubing is relatively easy, even for those without extensive experience in electronics or engineering. Here are the basic steps to follow:

- Choose the right type and size of shrink tubing for your project.

- Cut the tubing to the desired length using a pair of scissors or a craft knife.

- Slide the tubing over the object you want to insulate or protect.

- Apply heat to the tubing using a heat gun or a flame, until it shrinks to the desired size.

- Allow the tubing to cool and harden before handling.

5 Ways to Shrink Tubing

Here are 5 ways to shrink tubing: * Using a heat gun: This is one of the most common methods of shrinking tubing, and is relatively easy to do. * Using a flame: This method is similar to using a heat gun, but requires more caution and attention. * Using a shrink tubing tool: This is a specialized tool designed specifically for shrinking tubing, and can be more efficient and effective than other methods. * Using a hair dryer: This method is similar to using a heat gun, but may not be as effective for thicker or more dense tubing. * Using a heat shrink oven: This is a specialized oven designed specifically for shrinking tubing, and can be more efficient and effective than other methods.Shrink Tubing Image Gallery

What is shrink tubing?

+Shrink tubing is a type of plastic tubing that shrinks in size when exposed to heat, typically from a heat gun or a flame.

What are the benefits of using shrink tubing?

+The benefits of using shrink tubing include insulation and protection, identification and organization, ease of use, and versatility.

What are the different types of shrink tubing?

+The different types of shrink tubing include polyolefin, PVC, and Teflon, each with its own unique properties and advantages.

How do I use shrink tubing?

+To use shrink tubing, choose the right type and size, cut the tubing to the desired length, slide the tubing over the object, apply heat, and allow the tubing to cool and harden.

What are some common applications of shrink tubing?

+Some common applications of shrink tubing include insulating and protecting wires and cables, creating custom connectors and adapters, identifying and organizing cables, wires, and connectors, and protecting devices and systems from environmental factors.

In conclusion, shrink tubing is a versatile and essential tool that has numerous applications in electronics, engineering, and other fields. Its benefits, including insulation and protection, identification and organization, ease of use, and versatility, make it a popular choice among professionals and DIY enthusiasts alike. By understanding the different types of shrink tubing, their properties, and uses, individuals can effectively utilize this tool to achieve their goals. Whether you're looking to insulate wires, create custom connectors, or protect devices from environmental factors, shrink tubing is an excellent option to consider. With its ease of use, versatility, and effectiveness, shrink tubing is an indispensable tool that should be included in every toolkit. We hope this article has provided you with a comprehensive understanding of shrink tubing and its applications, and we encourage you to share your thoughts and experiences with us in the comments below.