Intro

Boost vinyl print quality with 5 expert tips, covering design, material, and application techniques for vibrant, durable results, including signage, decals, and sticker printing methods.

The world of vinyl printing has become increasingly popular in recent years, with many individuals and businesses looking to create unique and personalized items such as stickers, decals, and signs. Vinyl printing offers a versatile and cost-effective way to produce high-quality prints that can be used in a variety of applications. However, to achieve professional-looking results, it's essential to follow some key tips and guidelines. In this article, we'll explore five vinyl print tips to help you get the most out of your printing projects.

When it comes to vinyl printing, the quality of the print is only as good as the quality of the vinyl itself. That's why it's crucial to choose the right type of vinyl for your project. With so many different types of vinyl available, it can be overwhelming to decide which one to use. From calendared vinyl to cast vinyl, each type has its own unique characteristics and advantages. By understanding the differences between these types of vinyl, you can make an informed decision and ensure that your prints turn out as expected.

Understanding Vinyl Types

Preparing Your Design

Choosing the Right Printer

Applying the Vinyl

Troubleshooting Common Issues

Here are some additional tips to keep in mind when working with vinyl prints:

- Always follow the manufacturer's instructions for the specific type of vinyl you're using.

- Use a cutting mat or other protective surface to prevent damage to the vinyl during cutting.

- Apply the vinyl in a well-ventilated area to prevent the buildup of fumes and moisture.

- Avoid applying vinyl in extreme temperatures or weather conditions.

- Use a laminator to protect the print and extend its lifespan.

In addition to these tips, here are some benefits of using vinyl prints:

- Durability: Vinyl prints are highly resistant to fading, cracking, and peeling.

- Versatility: Vinyl prints can be used in a variety of applications, from signage and decals to vehicle wraps and architectural signage.

- Cost-effectiveness: Vinyl prints are a cost-effective way to produce high-quality prints, especially for short-term applications.

- Ease of use: Vinyl prints are relatively easy to apply and remove, making them a great option for temporary or promotional materials.

Some common applications of vinyl prints include:

- Signage: Vinyl prints are often used for signage, including event signage, promotional materials, and architectural signage.

- Decals: Vinyl prints can be used to create custom decals for vehicles, laptops, and other surfaces.

- Vehicle wraps: Vinyl prints are used to create custom vehicle wraps for cars, trucks, and other vehicles.

- Architectural signage: Vinyl prints are used to create custom signage for buildings, including lobby signs, directional signs, and informational signs.

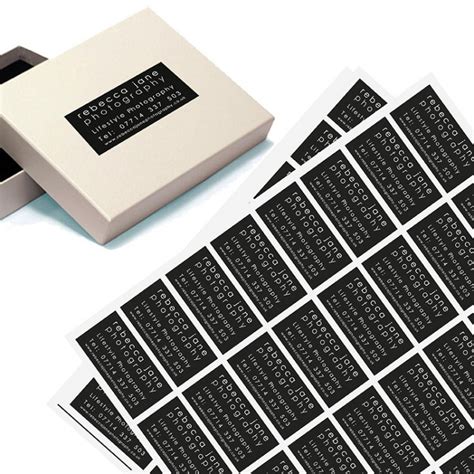

Gallery of Vinyl Prints

Vinyl Print Image Gallery

What is the best type of vinyl for outdoor use?

+The best type of vinyl for outdoor use is cast vinyl, which offers superior durability and resistance to fading and cracking.

How do I apply vinyl to a curved surface?

+To apply vinyl to a curved surface, use a heat gun or other application tool to slowly and evenly apply the vinyl, working from the center outwards.

Can I use vinyl prints for indoor applications?

+Yes, vinyl prints can be used for indoor applications, including signage, decals, and displays. They are a great option for temporary or promotional materials.

How long do vinyl prints last?

+The lifespan of vinyl prints depends on the type of vinyl used and the environmental conditions. On average, vinyl prints can last anywhere from 3 to 7 years, depending on the application and usage.

Can I laminate vinyl prints?

+Yes, vinyl prints can be laminated to protect them from fading, cracking, and peeling. Lamination can also extend the lifespan of the print and make it easier to clean and maintain.

In conclusion, vinyl printing is a versatile and cost-effective way to produce high-quality prints for a variety of applications. By following the tips and guidelines outlined in this article, you can achieve professional-looking results and make the most out of your printing projects. Whether you're a beginner or an experienced printer, vinyl prints offer a world of creative possibilities and can help you take your printing to the next level. So why not give vinyl printing a try and see what you can create? Share your experiences and tips with us in the comments below, and don't forget to share this article with your friends and colleagues who may be interested in vinyl printing.