Intro

Create organized cables with printable wire labels, made easy with customizable templates and adhesive labels for efficient cable management and identification solutions.

Organizing cables and wires can be a daunting task, especially in today's technology-driven world where devices and gadgets are omnipresent. The clutter of wires can lead to a messy workspace, increased risk of damage to the cables, and a significant waste of time spent searching for the right connection. This is where printable wire labels come into play, offering a simple yet effective solution to manage and identify cables efficiently. With the advancement in printing technology and the availability of various label-making tools, creating custom wire labels has never been easier.

The importance of wire management cannot be overstated. It not only contributes to a cleaner and safer environment but also enhances productivity by making it easier to locate and troubleshoot cables. Printable wire labels are a key component of this system, allowing users to clearly mark each cable with its destination, purpose, or any other relevant information. This clarity is invaluable in both professional settings, such as data centers and offices, and personal spaces, like home offices and entertainment systems.

For individuals looking to organize their workspace or enhance the efficiency of their cable management system, understanding the benefits and processes involved in creating printable wire labels is crucial. From the types of labels and printers available to the software and design techniques used, there's a wealth of information to explore. By delving into the world of printable wire labels, one can discover how this simple tool can revolutionize the way cables are managed, leading to a more organized, productive, and stress-free environment.

Understanding Printable Wire Labels

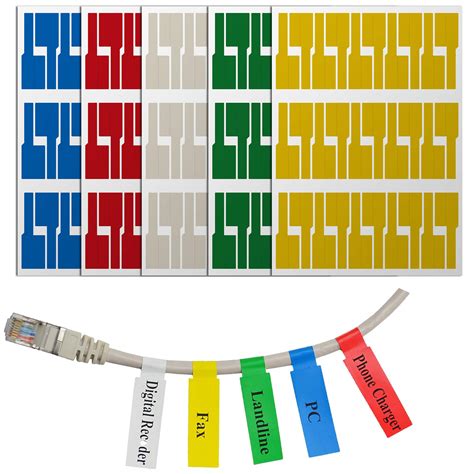

Printable wire labels are small pieces of adhesive paper or vinyl that can be printed with custom text or images to identify cables. These labels are designed to be durable and resistant to wear and tear, ensuring that the information remains legible over time. They come in various sizes, shapes, and materials, catering to different types of cables and environments. For instance, labels for indoor use might be made of standard paper or plastic, while those intended for outdoor or high-temperature environments might be made of more robust, weather-resistant materials.

Benefits of Using Printable Wire Labels

The benefits of using printable wire labels are multifaceted. They enhance the aesthetics of a workspace by keeping cables organized and out of sight. More importantly, they play a critical role in safety and efficiency. Clearly labeled cables reduce the risk of accidental disconnections or misconnections, which can lead to equipment damage or data loss. In professional settings, this can translate into significant cost savings and reduced downtime.Furthermore, printable wire labels contribute to a more efficient troubleshooting process. When cables are properly labeled, technicians can quickly identify the source of a problem, saving time and resources. This efficiency is particularly valuable in data centers and network operations, where minutes of downtime can result in substantial financial losses.

Choosing the Right Label Maker

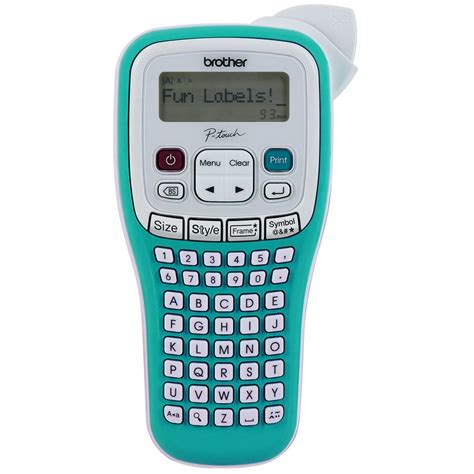

Selecting the appropriate label maker is a crucial step in creating printable wire labels. The market offers a wide range of label makers, from basic handheld devices to advanced desktop printers. The choice of label maker depends on several factors, including the volume of labels needed, the desired label size, and the level of durability required.

Handheld label makers are ideal for small-scale labeling needs. They are portable, easy to use, and often come with a keyboard for typing out labels. These devices are perfect for home offices or small businesses with minimal labeling requirements.

For larger operations or those requiring more advanced labeling capabilities, desktop label printers are the better option. These printers can produce labels at a higher speed and offer more sizing options. They often come with software that allows for the creation of custom labels with various fonts, colors, and designs.

Designing Effective Wire Labels

Designing effective wire labels involves more than just typing out the cable's name or destination. It requires careful consideration of the information that needs to be conveyed and how it will be displayed. Here are some tips for designing effective wire labels:- Clarity: Ensure that the text is clear and easy to read. Choose a font that is simple and of adequate size.

- Relevance: Only include relevant information on the label. Too much information can clutter the label and make it harder to read.

- Color: Utilize color to categorize cables or highlight important information. Different colors can be used for different types of cables or to indicate priority.

- Size: Select a label size that is appropriate for the cable it will be applied to. Larger cables may require larger labels for better visibility.

Printing and Applying Wire Labels

Once the design is finalized, the next step is printing the labels. This process varies depending on the label maker or printer being used. Most devices come with straightforward instructions for loading the label tape or sheets and printing the labels.

Applying the labels to the cables is just as important as designing and printing them. Here are a few tips to ensure that the labels are applied correctly:

- Clean the Cable: Before applying the label, make sure the cable is clean and dry. This ensures a strong adhesive bond and prevents the label from peeling off prematurely.

- Center the Label: Apply the label in the center of the cable or at a point that is easily accessible. This makes it easier to read the label without having to manipulate the cable.

- Smooth Out Air Bubbles: After applying the label, smooth out any air bubbles that may have formed. This prevents the label from lifting off over time.

Maintenance and Replacement

While printable wire labels are designed to be durable, they may eventually need to be replaced due to wear and tear or changes in the cable configuration. Regularly inspecting the labels and replacing them as needed is crucial for maintaining an organized and efficient cable management system.When replacing labels, it's a good opportunity to review the cable layout and make any necessary adjustments. This might involve relocating cables, adding new labels, or updating the information on existing labels.

Best Practices for Wire Labeling

Implementing best practices for wire labeling can significantly enhance the effectiveness of a cable management system. Here are some guidelines to follow:

- Standardize Labeling: Establish a standardized labeling system across all cables and devices. This makes it easier for anyone to understand the cable layout and find specific connections.

- Use Color Coding: Implement a color-coding system to categorize cables by type, priority, or destination. This visual system can quickly convey important information.

- Label Both Ends: Labeling both ends of a cable can be beneficial, especially in complex setups. This ensures that the cable can be identified regardless of which end is accessible.

Common Mistakes to Avoid

When implementing a wire labeling system, there are several common mistakes to avoid. These include:- Inconsistent Labeling: Failing to standardize the labeling system can lead to confusion and inefficiency.

- Insufficient Information: Not including enough information on the label can make it difficult to identify the cable's purpose or destination.

- Poor Label Quality: Using low-quality labels that are prone to fading or peeling off can undermine the effectiveness of the labeling system.

Gallery of Printable Wire Labels

Printable Wire Labels Gallery

Frequently Asked Questions

What are the benefits of using printable wire labels?

+Printable wire labels enhance organization, safety, and efficiency by clearly identifying cables, reducing the risk of misconnections, and facilitating quicker troubleshooting.

How do I choose the right label maker for my needs?

+Consider the volume of labels you need, the desired label size, and the level of durability required. Handheld label makers are suitable for small-scale needs, while desktop printers are better for larger operations or advanced labeling requirements.

What are some best practices for designing effective wire labels?

+Ensure clarity by using simple fonts and adequate sizing, include relevant information, utilize color coding for categorization, and standardize your labeling system across all cables and devices.

How often should I inspect and replace my wire labels?

+Regularly inspect your wire labels for wear and tear, and replace them as needed. This maintenance is crucial for ensuring the labels remain legible and the cable management system remains effective.

Can I use printable wire labels in outdoor or high-temperature environments?

+In conclusion, printable wire labels are a simple yet powerful tool for managing cables and enhancing the efficiency and safety of any workspace. By understanding the benefits, choosing the right label maker, designing effective labels, and following best practices, individuals can create a well-organized cable management system. Whether you're managing a complex network infrastructure or simply organizing your home office, printable wire labels can make a significant difference. We invite you to share your experiences with printable wire labels, ask questions, or provide tips on how you've implemented an effective cable management system in your workspace. Your input can help others navigate the world of wire labeling and discover the benefits it has to offer.