Intro

Discover 5 ways inventory programs streamline stock management, utilizing inventory control, tracking, and optimization techniques to boost efficiency and reduce costs, with effective inventory management solutions.

Effective inventory management is crucial for businesses to operate efficiently, reduce costs, and improve customer satisfaction. An inventory program can help organizations achieve these goals by streamlining inventory tracking, management, and optimization. In this article, we will explore five ways an inventory program can benefit businesses and provide tips on how to implement an effective inventory management system.

Inventory management is a critical component of any business, as it directly impacts the bottom line. When inventory levels are too high, businesses tie up valuable resources in unnecessary stock, which can lead to waste and obsolescence. On the other hand, when inventory levels are too low, businesses risk losing sales and damaging their reputation due to stockouts. An inventory program can help businesses strike the perfect balance between inventory levels and demand.

The importance of inventory management cannot be overstated. According to a study by the National Retail Federation, inventory shrinkage costs retailers an average of 1.33% of sales, which translates to billions of dollars in losses each year. Furthermore, a study by the Institute of Supply Management found that companies with effective inventory management systems experience significant improvements in fill rates, lead times, and inventory turnover.

Benefits of an Inventory Program

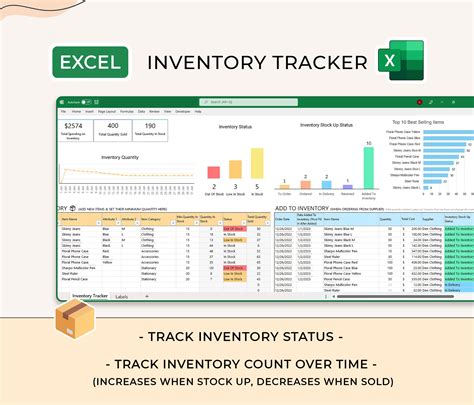

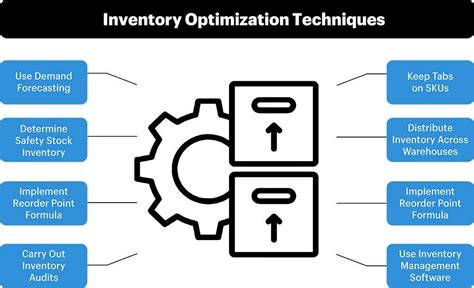

An inventory program offers numerous benefits to businesses, including improved accuracy, increased efficiency, and enhanced decision-making capabilities. With an inventory program, businesses can track inventory levels in real-time, automate inventory tracking and reporting, and optimize inventory levels based on demand and supply chain conditions.

Some of the key benefits of an inventory program include:

- Improved inventory accuracy: An inventory program can help businesses reduce inventory errors and discrepancies, which can lead to stockouts, overstocking, and waste.

- Increased efficiency: An inventory program can automate many inventory-related tasks, such as tracking, reporting, and ordering, which can free up staff to focus on higher-value activities.

- Enhanced decision-making: An inventory program can provide businesses with real-time data and insights on inventory levels, demand, and supply chain conditions, which can inform decision-making and drive business growth.

5 Ways an Inventory Program Can Benefit Businesses

An inventory program can benefit businesses in many ways, including:

- Improved Inventory Accuracy: An inventory program can help businesses improve inventory accuracy by automating inventory tracking and reporting. This can reduce inventory errors and discrepancies, which can lead to stockouts, overstocking, and waste.

- Increased Efficiency: An inventory program can automate many inventory-related tasks, such as tracking, reporting, and ordering, which can free up staff to focus on higher-value activities.

- Enhanced Decision-Making: An inventory program can provide businesses with real-time data and insights on inventory levels, demand, and supply chain conditions, which can inform decision-making and drive business growth.

- Reduced Costs: An inventory program can help businesses reduce inventory costs by optimizing inventory levels, minimizing waste, and improving supply chain efficiency.

- Improved Customer Satisfaction: An inventory program can help businesses improve customer satisfaction by ensuring that products are available when customers need them, which can lead to increased loyalty and retention.

Implementing an Effective Inventory Management System

Implementing an effective inventory management system requires careful planning, execution, and ongoing monitoring. Here are some tips to help businesses implement an effective inventory management system:

- Conduct an inventory audit: Conduct a thorough inventory audit to identify areas for improvement and develop a baseline understanding of current inventory levels and processes.

- Set inventory goals and objectives: Set clear inventory goals and objectives, such as improving inventory accuracy, reducing inventory costs, and improving customer satisfaction.

- Choose an inventory management system: Choose an inventory management system that meets the business's needs and provides real-time data and insights on inventory levels, demand, and supply chain conditions.

- Train staff: Train staff on the new inventory management system and provide ongoing support and training to ensure that staff are equipped to manage inventory effectively.

- Monitor and evaluate: Monitor and evaluate the effectiveness of the inventory management system regularly and make adjustments as needed to ensure that inventory goals and objectives are being met.

Best Practices for Inventory Management

Here are some best practices for inventory management that businesses can follow to optimize inventory levels and improve customer satisfaction:

- Use a first-in, first-out (FIFO) inventory system: Use a FIFO inventory system to ensure that older inventory is sold or used before newer inventory.

- Implement a just-in-time (JIT) inventory system: Implement a JIT inventory system to minimize inventory levels and reduce waste.

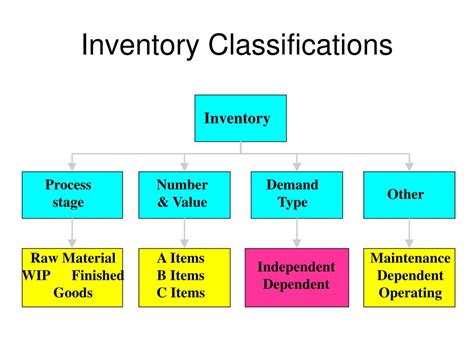

- Use inventory classification: Use inventory classification to categorize inventory into different categories, such as fast-moving, slow-moving, and dead stock.

- Conduct regular inventory audits: Conduct regular inventory audits to identify areas for improvement and develop a baseline understanding of current inventory levels and processes.

- Use data and analytics: Use data and analytics to inform inventory decisions and optimize inventory levels based on demand and supply chain conditions.

Common Inventory Management Mistakes to Avoid

Here are some common inventory management mistakes to avoid:

- Overstocking: Overstocking can lead to waste, obsolescence, and unnecessary inventory costs.

- Understocking: Understocking can lead to stockouts, lost sales, and damaged customer relationships.

- Poor inventory tracking: Poor inventory tracking can lead to inventory errors and discrepancies, which can lead to stockouts, overstocking, and waste.

- Inadequate inventory reporting: Inadequate inventory reporting can lead to poor decision-making and a lack of visibility into inventory levels and supply chain conditions.

- Failure to implement a inventory management system: Failure to implement a inventory management system can lead to inefficient inventory management, poor decision-making, and a lack of visibility into inventory levels and supply chain conditions.

Gallery of Inventory Management

Inventory Management Image Gallery

What is inventory management?

+Inventory management refers to the process of planning, organizing, and controlling the flow of goods, products, and materials from raw materials to finished goods.

Why is inventory management important?

+Inventory management is important because it helps businesses to optimize inventory levels, reduce costs, and improve customer satisfaction.

What are the benefits of using an inventory management system?

+The benefits of using an inventory management system include improved inventory accuracy, increased efficiency, enhanced decision-making, reduced costs, and improved customer satisfaction.

How can businesses implement an effective inventory management system?

+Businesses can implement an effective inventory management system by conducting an inventory audit, setting inventory goals and objectives, choosing an inventory management system, training staff, and monitoring and evaluating the effectiveness of the system.

What are some common inventory management mistakes to avoid?

+Some common inventory management mistakes to avoid include overstocking, understocking, poor inventory tracking, inadequate inventory reporting, and failure to implement a inventory management system.

In conclusion, an inventory program is a valuable tool for businesses to optimize inventory levels, reduce costs, and improve customer satisfaction. By understanding the benefits of an inventory program, implementing an effective inventory management system, and avoiding common inventory management mistakes, businesses can achieve significant improvements in inventory management and drive business growth. We invite readers to share their experiences and insights on inventory management and to ask questions or seek advice on implementing an effective inventory management system.