Intro

Optimize inventory control with 5 ways inventory management, utilizing stock tracking, supply chain optimization, and warehouse management to improve logistics and reduce costs, enhancing overall operational efficiency.

Effective inventory management is crucial for businesses to operate efficiently, reduce costs, and improve customer satisfaction. Inventory management refers to the process of tracking, managing, and optimizing the inventory levels of a company. It involves ensuring that the right products are available at the right time, in the right quantities, and at the right cost. In this article, we will discuss the importance of inventory management and explore five ways to improve inventory management in your business.

Inventory management is a critical function that can make or break a business. When done correctly, it can help companies to reduce waste, improve cash flow, and increase profitability. On the other hand, poor inventory management can lead to stockouts, overstocking, and unnecessary expenses. As a business owner, it is essential to understand the importance of inventory management and implement effective strategies to optimize your inventory levels.

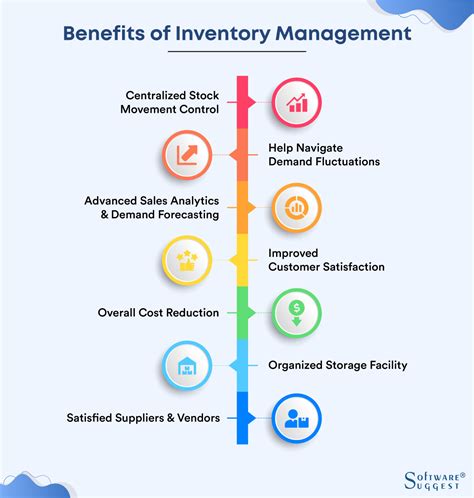

Inventory management involves several key activities, including tracking inventory levels, managing stockroom operations, and optimizing inventory levels. It also involves analyzing sales data, forecasting demand, and making informed decisions about inventory replenishment. By implementing effective inventory management strategies, businesses can improve their bottom line, enhance customer satisfaction, and gain a competitive edge in the market.

Understanding Inventory Management

Benefits of Inventory Management

5 Ways to Improve Inventory Management

Inventory Management Best Practices

Common Inventory Management Mistakes

Inventory Management Tools and Techniques

Gallery of Inventory Management

Inventory Management Image Gallery

What is inventory management?

+Inventory management refers to the process of tracking, managing, and optimizing the inventory levels of a company.

Why is inventory management important?

+Inventory management is important because it helps businesses to reduce waste, minimize stockouts, and avoid overstocking. It also enables businesses to respond quickly to changes in demand, improve customer satisfaction, and gain a competitive edge in the market.

What are some common inventory management mistakes?

+Some common inventory management mistakes include overstocking or understocking, failing to analyze sales data and forecast demand, not implementing a robust inventory management system, and not providing training to inventory management staff.

What are some inventory management best practices?

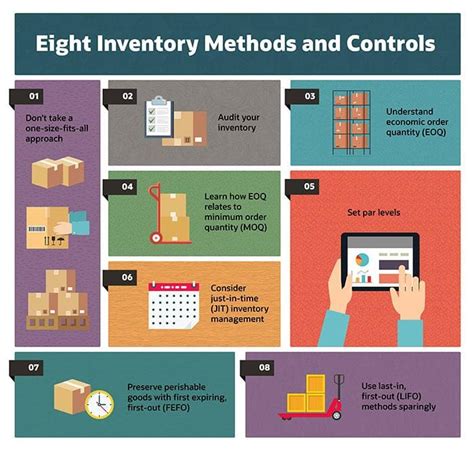

+Some inventory management best practices include implementing a robust inventory management system, analyzing sales data and forecasting demand, implementing just-in-time inventory management, using inventory optimization techniques, and monitoring and adjusting inventory levels regularly.

What are some inventory management tools and techniques?

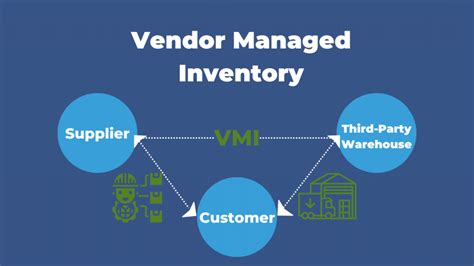

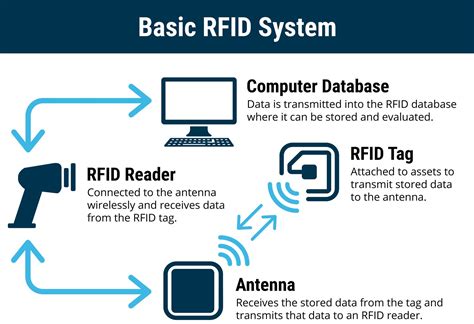

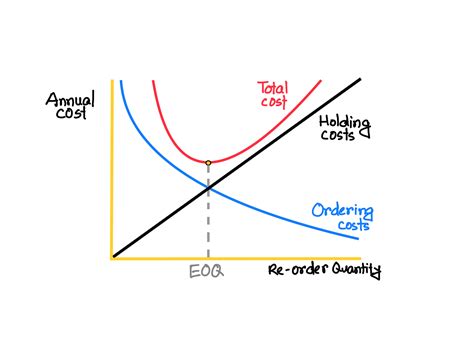

+Some inventory management tools and techniques include inventory management software, barcode scanning and RFID technology, inventory optimization models, just-in-time inventory management, vendor-managed inventory, and drop shipping.

In conclusion, effective inventory management is crucial for businesses to operate efficiently, reduce costs, and improve customer satisfaction. By implementing a robust inventory management system, analyzing sales data and forecasting demand, implementing just-in-time inventory management, using inventory optimization techniques, and monitoring and adjusting inventory levels regularly, businesses can improve their bottom line, enhance customer satisfaction, and gain a competitive edge in the market. We hope this article has provided you with valuable insights and practical tips on how to improve inventory management in your business. If you have any questions or comments, please feel free to share them with us.