Intro

Unlock trading success with 5 Stock Days Formula Tips, featuring stock market strategies, day trading techniques, and investment insights for profitable returns and risk management.

The 5 stock days formula is a crucial concept in inventory management, enabling businesses to balance stock levels, minimize waste, and maximize profitability. Understanding and applying this formula can significantly impact a company's bottom line, making it essential for entrepreneurs, inventory managers, and business owners to grasp its intricacies. In this article, we will delve into the world of inventory management, exploring the importance of the 5 stock days formula, its benefits, and provide actionable tips for its implementation.

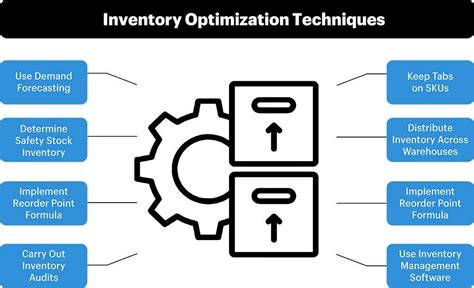

Effective inventory management is the backbone of any successful business, especially those in the retail, manufacturing, and distribution sectors. It involves a delicate balance between meeting customer demand and avoiding overstocking, which can lead to unnecessary expenses and reduced profitability. The 5 stock days formula offers a straightforward yet powerful approach to achieving this balance, ensuring that businesses maintain optimal stock levels to meet customer needs while minimizing excess inventory.

The concept of the 5 stock days formula is rooted in the idea that businesses should aim to hold just enough stock to meet customer demand over a short period, typically five days. This approach allows companies to respond quickly to changes in demand, reduce inventory holding costs, and improve cash flow. By adopting the 5 stock days formula, businesses can streamline their inventory management processes, making them more agile and responsive to market fluctuations.

Understanding the 5 Stock Days Formula

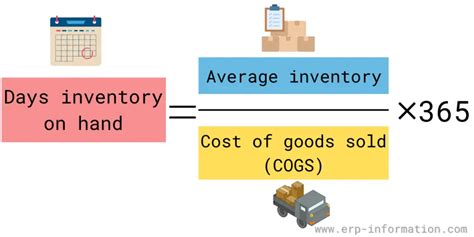

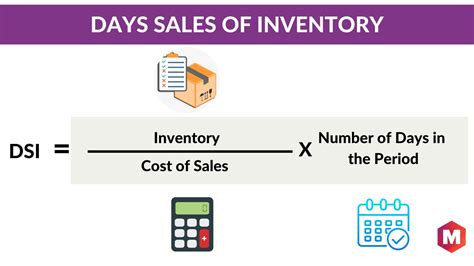

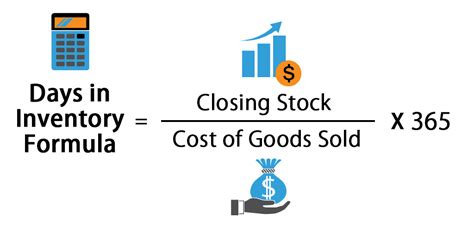

To apply the 5 stock days formula effectively, businesses must first understand its underlying principles. The formula involves calculating the optimal stock level based on historical sales data, lead times, and service levels. This calculation takes into account the average daily demand for a product, the lead time required to replenish stock, and the desired service level, which is the percentage of customer demand that should be met from existing stock.

Benefits of the 5 Stock Days Formula

The benefits of implementing the 5 stock days formula are multifaceted, ranging from reduced inventory holding costs to improved customer service levels. By maintaining optimal stock levels, businesses can minimize the risk of stockouts and overstocking, both of which can have significant financial implications. Moreover, the 5 stock days formula enables companies to respond more quickly to changes in demand, improving their competitiveness in the market.

Some of the key benefits of the 5 stock days formula include:

- Reduced inventory holding costs: By minimizing excess inventory, businesses can lower their storage, maintenance, and insurance costs.

- Improved cash flow: The 5 stock days formula helps companies avoid tying up large amounts of capital in inventory, improving their cash flow and financial flexibility.

- Enhanced customer service: By ensuring that stock levels are optimal, businesses can meet customer demand more effectively, leading to higher customer satisfaction levels.

- Increased agility: The 5 stock days formula allows companies to respond quickly to changes in demand, making them more agile and competitive in the market.

Implementing the 5 Stock Days Formula

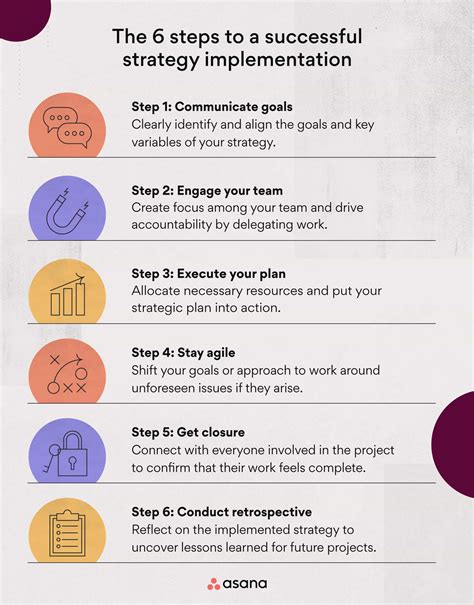

Implementing the 5 stock days formula requires a systematic approach, involving several key steps. First, businesses must gather historical sales data to understand demand patterns and trends. This data should be analyzed to determine the average daily demand for each product, taking into account seasonal fluctuations and other factors that may influence demand.

Next, companies must calculate the lead time required to replenish stock, which can vary depending on the supplier, transportation methods, and other logistical factors. The desired service level should also be determined, based on the company's customer service goals and industry benchmarks.

With these factors in place, the 5 stock days formula can be applied to calculate the optimal stock level for each product. This involves multiplying the average daily demand by the lead time and then adjusting for the desired service level.

Key Considerations for Implementation

When implementing the 5 stock days formula, there are several key considerations that businesses should keep in mind. These include: - Data accuracy: The 5 stock days formula relies on accurate historical sales data, so it's essential to ensure that this data is reliable and up-to-date. - Demand variability: Businesses should consider demand variability when applying the 5 stock days formula, as this can impact the optimal stock level. - Lead time variability: Lead times can also vary, depending on the supplier and logistical factors, so businesses should factor this into their calculations. - Service level agreements: Companies should review their service level agreements with customers to ensure that the 5 stock days formula aligns with these commitments.Tips for Effective Implementation

To ensure effective implementation of the 5 stock days formula, businesses should follow several tips. These include:

- Monitor and adjust: Continuously monitor inventory levels and adjust the 5 stock days formula as needed to reflect changes in demand or lead times.

- Consider inventory classification: Classify inventory into different categories based on demand and lead time, and apply the 5 stock days formula accordingly.

- Implement a just-in-time (JIT) system: Consider implementing a JIT system to minimize inventory holding costs and improve cash flow.

- Review and revise: Regularly review and revise the 5 stock days formula to ensure it remains aligned with business goals and market conditions.

Common Challenges and Solutions

When implementing the 5 stock days formula, businesses may encounter several common challenges. These can include data inaccuracies, demand variability, and lead time uncertainties. To overcome these challenges, companies can adopt several strategies, such as:

- Implementing data analytics tools to improve data accuracy

- Using forecasting techniques to predict demand variability

- Developing relationships with suppliers to reduce lead times and improve delivery reliability

By understanding these challenges and implementing effective solutions, businesses can ensure successful implementation of the 5 stock days formula and achieve the associated benefits.

Best Practices for Inventory Management

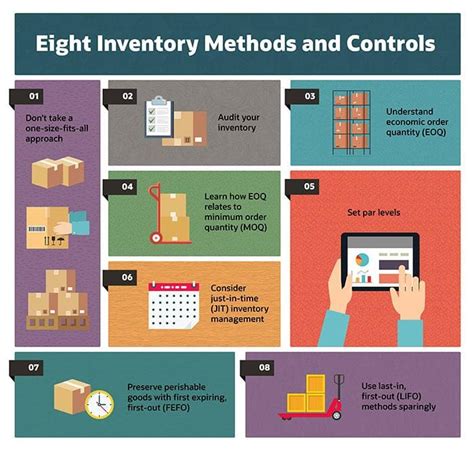

In addition to implementing the 5 stock days formula, businesses should adopt best practices for inventory management to maximize their inventory investment. These best practices include:

- Regular inventory audits to ensure data accuracy

- Implementing a first-in, first-out (FIFO) inventory system to minimize obsolescence

- Using inventory management software to streamline processes and improve visibility

- Providing training to inventory management staff to ensure they understand the 5 stock days formula and its application

By combining the 5 stock days formula with these best practices, businesses can achieve optimal inventory levels, reduce waste, and improve customer satisfaction.

Gallery of Inventory Management

Inventory Management Image Gallery

What is the 5 stock days formula?

+The 5 stock days formula is a method used to calculate the optimal stock level for a product based on historical sales data, lead times, and service levels.

How does the 5 stock days formula benefit businesses?

+The 5 stock days formula helps businesses reduce inventory holding costs, improve cash flow, and enhance customer service levels by ensuring optimal stock levels.

What are the key considerations for implementing the 5 stock days formula?

+Key considerations include data accuracy, demand variability, lead time variability, and service level agreements.

How can businesses overcome common challenges when implementing the 5 stock days formula?

+Businesses can overcome common challenges by implementing data analytics tools, using forecasting techniques, and developing relationships with suppliers.

What are some best practices for inventory management that businesses should adopt?

+Best practices include regular inventory audits, implementing a FIFO inventory system, using inventory management software, and providing training to inventory management staff.

In conclusion, the 5 stock days formula is a powerful tool for businesses looking to optimize their inventory management processes. By understanding the formula's underlying principles, benefits, and implementation tips, companies can reduce waste, improve customer satisfaction, and increase profitability. We invite readers to share their experiences with inventory management and the 5 stock days formula, and to explore the resources provided in this article to improve their inventory management practices. Whether you are a seasoned inventory manager or just starting to explore the world of inventory management, we encourage you to take the first step towards optimizing your inventory levels and achieving the associated benefits.