Intro

Boost inventory control with 5 stock management tips, including inventory tracking, supply chain optimization, and warehouse management, to improve logistics and reduce stockouts, overstocking, and dead stock, ensuring efficient stock control and increased profitability.

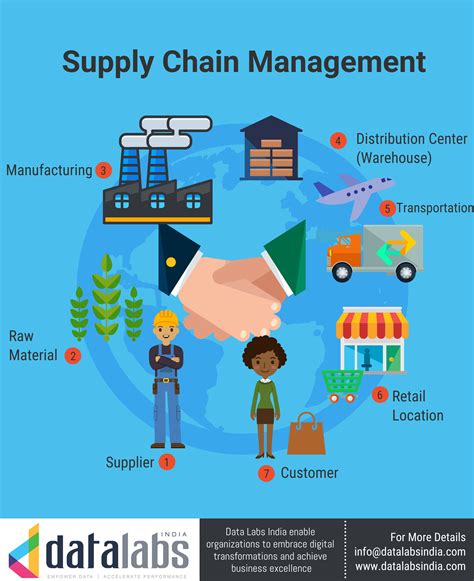

Effective stock management is crucial for businesses to maintain a competitive edge in the market. It involves tracking and controlling the flow of goods, products, or materials from production to distribution. Proper stock management helps companies reduce costs, improve customer satisfaction, and increase profitability. In this article, we will discuss five essential stock management tips that can help businesses optimize their inventory levels and streamline their operations.

The importance of stock management cannot be overstated. It has a direct impact on a company's bottom line, as excess inventory can lead to unnecessary expenses, while stockouts can result in lost sales and damaged customer relationships. Moreover, effective stock management enables businesses to respond quickly to changes in demand, ensuring that they can meet customer needs and stay ahead of the competition. With the rise of e-commerce and global supply chains, stock management has become more complex, making it essential for companies to adopt efficient strategies to manage their inventory.

In today's fast-paced business environment, companies must be agile and responsive to changing market conditions. Stock management plays a critical role in enabling businesses to adapt to shifts in demand, supply chain disruptions, and other external factors. By implementing effective stock management practices, companies can reduce the risk of stockouts, overstocking, and obsolescence, ultimately improving their overall performance and competitiveness. Whether you are a small business owner or a large enterprise, stock management is a critical aspect of your operations that requires careful attention and planning.

Understanding Your Inventory

Inventory Classification

Inventory classification is a critical step in understanding your inventory. It involves categorizing your products into different groups based on their characteristics, such as value, volume, and velocity. By classifying your inventory, you can prioritize your stock management efforts, focusing on high-value or fast-moving items. Inventory classification also helps you identify slow-moving or obsolete products, enabling you to take corrective action to minimize waste and reduce costs.Implementing a Stock Management System

Key Features of a Stock Management System

A good stock management system should have several key features, including inventory tracking, reporting, and analytics. It should also provide real-time visibility into stock levels, enabling you to make informed decisions about ordering and distribution. Other essential features of a stock management system include automated ordering, barcode scanning, and integration with other business applications. By choosing a stock management system with these features, you can optimize your inventory management processes and improve your overall business performance.Optimizing Stock Levels

Benefits of Optimizing Stock Levels

Optimizing stock levels has several benefits, including reduced waste, minimized costs, and improved customer satisfaction. By avoiding overstocking, you can reduce the risk of obsolescence, damage, and theft. Optimizing stock levels also enables you to respond quickly to changes in demand, ensuring that you can meet customer needs and stay ahead of the competition. Additionally, optimizing stock levels can help you improve your cash flow, as you will not be tying up capital in excess inventory.Managing Inventory Risk

Strategies for Managing Inventory Risk

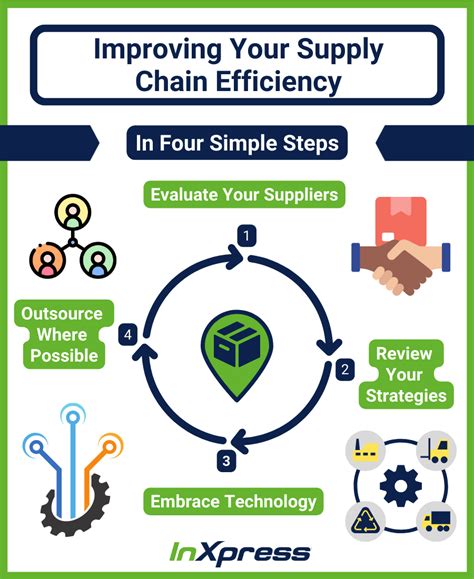

There are several strategies for managing inventory risk, including diversification, hedging, and inventory optimization. Diversification involves spreading your inventory across different products, suppliers, and locations to minimize the risk of stockouts or overstocking. Hedging involves using financial instruments, such as futures contracts, to mitigate the risk of price fluctuations. Inventory optimization involves analyzing your sales data and product movements to identify areas of inefficiency and opportunities for improvement.Improving Supply Chain Efficiency

Benefits of Improving Supply Chain Efficiency

Improving supply chain efficiency has several benefits, including reduced costs, improved customer satisfaction, and increased competitiveness. By streamlining your logistics and distribution processes, you can minimize delays, reduce the risk of stockouts or overstocking, and improve your overall business performance. Additionally, improving supply chain efficiency can help you respond quickly to changes in demand, ensuring that you can meet customer needs and stay ahead of the competition.Stock Management Image Gallery

What is stock management?

+Stock management refers to the process of tracking and controlling the flow of goods, products, or materials from production to distribution.

Why is stock management important?

+Stock management is important because it helps businesses reduce costs, improve customer satisfaction, and increase profitability.

What are the benefits of optimizing stock levels?

+The benefits of optimizing stock levels include reduced waste, minimized costs, and improved customer satisfaction.

How can I improve supply chain efficiency?

+You can improve supply chain efficiency by streamlining your logistics and distribution processes, analyzing your supply chain operations, and implementing strategies to optimize them.

What is a stock management system?

+A stock management system is a software application that helps businesses track and manage their inventory, providing real-time visibility into stock levels and enabling informed decisions about ordering and distribution.

In conclusion, effective stock management is critical to the success of any business. By understanding your inventory, implementing a stock management system, optimizing stock levels, managing inventory risk, and improving supply chain efficiency, you can reduce costs, improve customer satisfaction, and increase profitability. Remember to stay up-to-date with the latest trends and best practices in stock management, and don't hesitate to reach out to experts if you need help optimizing your inventory management processes. Share your thoughts and experiences with stock management in the comments below, and don't forget to share this article with your colleagues and friends who may benefit from these valuable tips.