Intro

Optimize warehouse operations with inventory control software, streamlining stock management, tracking, and logistics, using automated tools and real-time analytics for efficient supply chain management and inventory optimization.

Effective warehouse management is crucial for businesses to ensure timely and efficient delivery of products to customers. One of the key components of warehouse management is inventory control, which involves tracking and managing the stock levels, storage, and movement of goods within the warehouse. With the increasing complexity of supply chains and the growing demand for faster and more accurate order fulfillment, warehouse inventory control software has become an essential tool for businesses to optimize their inventory management processes.

In today's fast-paced and competitive business environment, companies need to be able to respond quickly to changing market conditions and customer demands. Warehouse inventory control software provides businesses with the visibility and control they need to manage their inventory effectively, reduce costs, and improve customer satisfaction. By automating many of the manual processes involved in inventory management, such as tracking stock levels, monitoring inventory movements, and generating reports, warehouse inventory control software helps businesses to streamline their operations, reduce errors, and improve productivity.

The importance of effective inventory management cannot be overstated. Inventory is a significant asset for many businesses, and poor inventory management can result in stockouts, overstocking, and obsolescence, leading to lost sales, wasted resources, and reduced profitability. Warehouse inventory control software helps businesses to avoid these problems by providing real-time visibility into inventory levels, enabling them to make informed decisions about inventory replenishment, storage, and shipping. By optimizing inventory levels and reducing inventory turnover, businesses can minimize waste, reduce costs, and improve their bottom line.

Benefits of Warehouse Inventory Control Software

Warehouse inventory control software offers numerous benefits to businesses, including improved inventory accuracy, reduced inventory costs, and enhanced customer satisfaction. By automating inventory tracking and management, businesses can reduce the risk of human error, improve inventory visibility, and make more informed decisions about inventory replenishment and shipping. Warehouse inventory control software also enables businesses to optimize their inventory levels, reduce inventory turnover, and minimize waste, resulting in significant cost savings.

Some of the key benefits of warehouse inventory control software include:

- Improved inventory accuracy: Warehouse inventory control software helps businesses to track inventory levels in real-time, reducing the risk of stockouts, overstocking, and inventory discrepancies.

- Reduced inventory costs: By optimizing inventory levels and reducing inventory turnover, businesses can minimize waste, reduce storage costs, and improve their bottom line.

- Enhanced customer satisfaction: Warehouse inventory control software enables businesses to respond quickly to customer demands, improving order fulfillment rates and reducing lead times.

- Improved supply chain visibility: Warehouse inventory control software provides businesses with real-time visibility into inventory levels, enabling them to make informed decisions about inventory replenishment, storage, and shipping.

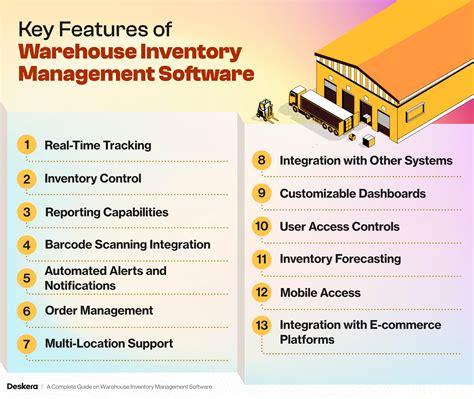

Key Features of Warehouse Inventory Control Software

Warehouse inventory control software typically includes a range of features designed to support inventory management, tracking, and optimization. Some of the key features of warehouse inventory control software include: * Inventory tracking: Warehouse inventory control software enables businesses to track inventory levels in real-time, including stock levels, inventory movements, and inventory storage. * Barcode scanning: Barcode scanning technology enables businesses to quickly and accurately track inventory movements, reducing the risk of human error and improving inventory accuracy. * Reporting and analytics: Warehouse inventory control software provides businesses with real-time reporting and analytics, enabling them to make informed decisions about inventory replenishment, storage, and shipping. * Inventory optimization: Warehouse inventory control software includes tools and algorithms designed to optimize inventory levels, reduce inventory turnover, and minimize waste.How Warehouse Inventory Control Software Works

Warehouse inventory control software works by automating many of the manual processes involved in inventory management. The software typically includes a range of features and tools designed to support inventory tracking, management, and optimization. Here's an overview of how warehouse inventory control software works:

- Inventory tracking: The software tracks inventory levels in real-time, including stock levels, inventory movements, and inventory storage.

- Barcode scanning: The software uses barcode scanning technology to quickly and accurately track inventory movements, reducing the risk of human error and improving inventory accuracy.

- Reporting and analytics: The software provides real-time reporting and analytics, enabling businesses to make informed decisions about inventory replenishment, storage, and shipping.

- Inventory optimization: The software includes tools and algorithms designed to optimize inventory levels, reduce inventory turnover, and minimize waste.

Steps to Implement Warehouse Inventory Control Software

Implementing warehouse inventory control software requires careful planning and execution. Here are the steps to implement warehouse inventory control software: * Step 1: Define inventory management goals and objectives * Step 2: Assess current inventory management processes and systems * Step 3: Evaluate warehouse inventory control software options * Step 4: Select a software solution that meets business needs * Step 5: Configure and customize the software * Step 6: Train staff on the new software * Step 7: Test and implement the softwareBest Practices for Using Warehouse Inventory Control Software

To get the most out of warehouse inventory control software, businesses should follow best practices for using the software. Here are some best practices to consider:

- Regularly update inventory levels and track inventory movements

- Use barcode scanning technology to improve inventory accuracy

- Analyze reporting and analytics to make informed decisions about inventory replenishment, storage, and shipping

- Optimize inventory levels and reduce inventory turnover

- Train staff on the software and ensure they understand how to use it effectively

Common Challenges and Solutions

Warehouse inventory control software can help businesses to overcome common challenges associated with inventory management, such as stockouts, overstocking, and inventory discrepancies. Here are some common challenges and solutions: * Challenge: Stockouts Solution: Implement a just-in-time inventory system to ensure that inventory levels are optimized and replenished in a timely manner. * Challenge: Overstocking Solution: Use inventory optimization tools to reduce inventory levels and minimize waste. * Challenge: Inventory discrepancies Solution: Use barcode scanning technology to improve inventory accuracy and reduce the risk of human error.Future of Warehouse Inventory Control Software

The future of warehouse inventory control software is exciting and rapidly evolving. As technology continues to advance, we can expect to see new features and innovations that will further improve inventory management and optimization. Some of the trends that are likely to shape the future of warehouse inventory control software include:

- Artificial intelligence and machine learning

- Internet of Things (IoT) technology

- Cloud-based software solutions

- Mobile devices and apps

Conclusion and Final Thoughts

In conclusion, warehouse inventory control software is a powerful tool that can help businesses to optimize their inventory management processes, reduce costs, and improve customer satisfaction. By automating many of the manual processes involved in inventory management, warehouse inventory control software enables businesses to streamline their operations, reduce errors, and improve productivity. As the technology continues to evolve, we can expect to see new features and innovations that will further improve inventory management and optimization.Warehouse Inventory Control Software Image Gallery

What is warehouse inventory control software?

+Warehouse inventory control software is a type of software that helps businesses to manage and track their inventory levels, storage, and movement within the warehouse.

What are the benefits of using warehouse inventory control software?

+The benefits of using warehouse inventory control software include improved inventory accuracy, reduced inventory costs, and enhanced customer satisfaction.

How does warehouse inventory control software work?

+Warehouse inventory control software works by automating many of the manual processes involved in inventory management, including tracking inventory levels, monitoring inventory movements, and generating reports.

What are the key features of warehouse inventory control software?

+The key features of warehouse inventory control software include inventory tracking, barcode scanning, reporting and analytics, and inventory optimization.

How can I implement warehouse inventory control software in my business?

+To implement warehouse inventory control software in your business, you should define your inventory management goals and objectives, assess your current inventory management processes and systems, evaluate software options, select a software solution that meets your needs, configure and customize the software, train your staff, and test and implement the software.

We hope this article has provided you with a comprehensive overview of warehouse inventory control software and its benefits, features, and implementation. If you have any further questions or would like to learn more about how warehouse inventory control software can help your business, please don't hesitate to contact us. We would be happy to hear from you and provide you with more information and resources. Additionally, we encourage you to share this article with others who may be interested in learning more about warehouse inventory control software and its benefits.