Intro

Optimize storage with a Warehouse Inventory Management System, utilizing inventory control, tracking, and logistics to streamline operations, boost efficiency, and reduce costs.

Effective warehouse inventory management is crucial for businesses to ensure they can meet customer demand, reduce costs, and improve overall efficiency. A well-organized warehouse inventory management system enables companies to keep track of their stock levels, monitor inventory movement, and make informed decisions about their supply chain. In today's fast-paced business environment, having a reliable and efficient warehouse inventory management system is essential for staying competitive.

The importance of a warehouse inventory management system cannot be overstated. Without a proper system in place, businesses risk facing a range of challenges, including stockouts, overstocking, and missed shipments. These issues can lead to lost sales, damaged relationships with customers, and a significant impact on the bottom line. On the other hand, a well-designed warehouse inventory management system can help businesses to streamline their operations, reduce errors, and improve customer satisfaction.

In recent years, the development of technology has transformed the way businesses manage their warehouse inventory. Advances in software, hardware, and data analytics have enabled companies to implement sophisticated inventory management systems that can track inventory levels in real-time, automate tasks, and provide valuable insights into inventory trends. As a result, businesses can now make more informed decisions about their inventory, reduce waste, and improve their overall efficiency.

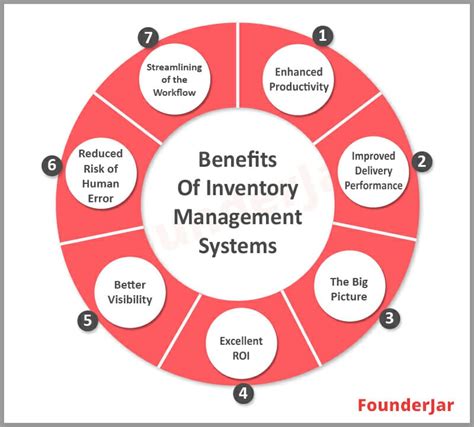

Benefits of a Warehouse Inventory Management System

A warehouse inventory management system offers a range of benefits for businesses. Some of the key advantages include:

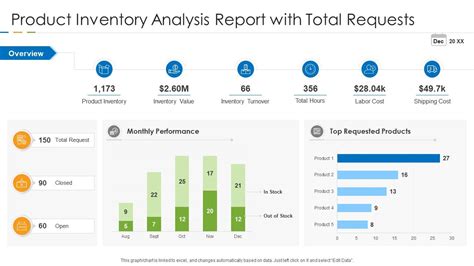

- Improved inventory accuracy: A warehouse inventory management system enables businesses to track their inventory levels in real-time, reducing the risk of errors and discrepancies.

- Increased efficiency: Automation and streamlined processes can help to reduce labor costs, improve productivity, and speed up inventory movement.

- Better decision-making: With access to real-time data and analytics, businesses can make more informed decisions about their inventory, including when to restock, how much to order, and how to optimize their supply chain.

- Enhanced customer satisfaction: By ensuring that inventory levels are accurate and up-to-date, businesses can improve their ability to meet customer demand, reducing the risk of stockouts and missed shipments.

- Reduced costs: A warehouse inventory management system can help businesses to reduce waste, minimize overstocking, and optimize their inventory levels, leading to significant cost savings.

Key Components of a Warehouse Inventory Management System

A warehouse inventory management system typically consists of several key components, including:

- Inventory tracking software: This is the core of the system, enabling businesses to track their inventory levels, monitor inventory movement, and analyze inventory trends.

- Barcode scanning and labeling: Barcode scanning and labeling enable businesses to quickly and accurately track inventory movement, reducing the risk of errors and discrepancies.

- Automated storage and retrieval systems: These systems use automated equipment, such as conveyor belts and robotic arms, to store and retrieve inventory, improving efficiency and reducing labor costs.

- Inventory reporting and analytics: This component provides businesses with real-time data and analytics, enabling them to make informed decisions about their inventory and optimize their supply chain.

- Integration with other business systems: A warehouse inventory management system should be integrated with other business systems, such as enterprise resource planning (ERP) and customer relationship management (CRM) systems, to ensure seamless communication and data sharing.

Types of Warehouse Inventory Management Systems

There are several types of warehouse inventory management systems available, including:

- Manual systems: These systems rely on manual data entry and tracking, and are often used by small businesses or those with simple inventory needs.

- Automated systems: These systems use automated equipment and software to track inventory levels and monitor inventory movement.

- Hybrid systems: These systems combine manual and automated components, offering a flexible and scalable solution for businesses with complex inventory needs.

- Cloud-based systems: These systems are hosted in the cloud, enabling businesses to access their inventory data from anywhere, at any time.

- On-premise systems: These systems are hosted on-site, providing businesses with complete control over their inventory data and systems.

Implementing a Warehouse Inventory Management System

Implementing a warehouse inventory management system requires careful planning and execution. Some key steps to consider include:

- Assessing inventory needs: Businesses should assess their inventory needs, including the types of products they store, the volume of inventory, and the frequency of inventory movement.

- Selecting a system: Businesses should select a warehouse inventory management system that meets their needs, including the type of system, the level of automation, and the scalability of the system.

- Configuring the system: The system should be configured to meet the specific needs of the business, including setting up inventory tracking software, barcode scanning and labeling, and automated storage and retrieval systems.

- Training staff: Staff should be trained on the use of the system, including how to track inventory, monitor inventory movement, and analyze inventory trends.

- Testing and evaluating: The system should be tested and evaluated to ensure it is working correctly, and any issues or discrepancies are addressed.

Best Practices for Warehouse Inventory Management

Some best practices for warehouse inventory management include:

- Implementing a first-in, first-out (FIFO) inventory system, where the oldest inventory is sold or used first.

- Using barcode scanning and labeling to track inventory movement and reduce errors.

- Implementing automated storage and retrieval systems to improve efficiency and reduce labor costs.

- Providing regular training and support for staff, to ensure they are comfortable using the system and can troubleshoot any issues.

- Continuously monitoring and evaluating the system, to identify areas for improvement and optimize inventory levels.

Common Challenges in Warehouse Inventory Management

Some common challenges in warehouse inventory management include:

- Inaccurate inventory tracking: This can lead to stockouts, overstocking, and missed shipments.

- Insufficient training: Staff may not be comfortable using the system, leading to errors and discrepancies.

- Inadequate system maintenance: The system may not be properly maintained, leading to technical issues and downtime.

- Lack of scalability: The system may not be able to handle increases in inventory volume or complexity.

- Integration issues: The system may not integrate seamlessly with other business systems, leading to data discrepancies and communication breakdowns.

Gallery of Warehouse Inventory Management

Warehouse Inventory Management Image Gallery

What is a warehouse inventory management system?

+A warehouse inventory management system is a software or hardware solution that enables businesses to track and manage their inventory levels, monitor inventory movement, and analyze inventory trends.

What are the benefits of a warehouse inventory management system?

+The benefits of a warehouse inventory management system include improved inventory accuracy, increased efficiency, better decision-making, enhanced customer satisfaction, and reduced costs.

How do I implement a warehouse inventory management system?

+To implement a warehouse inventory management system, businesses should assess their inventory needs, select a system, configure the system, train staff, and test and evaluate the system.

What are some common challenges in warehouse inventory management?

+Some common challenges in warehouse inventory management include inaccurate inventory tracking, insufficient training, inadequate system maintenance, lack of scalability, and integration issues.

How can I improve my warehouse inventory management?

+Businesses can improve their warehouse inventory management by implementing a first-in, first-out (FIFO) inventory system, using barcode scanning and labeling, implementing automated storage and retrieval systems, providing regular training and support for staff, and continuously monitoring and evaluating the system.

In conclusion, a warehouse inventory management system is a critical component of any business that wants to stay competitive in today's fast-paced market. By understanding the benefits, key components, and best practices of a warehouse inventory management system, businesses can improve their inventory accuracy, increase efficiency, and reduce costs. Whether you're a small business or a large enterprise, implementing a warehouse inventory management system can have a significant impact on your bottom line. We encourage you to share your thoughts and experiences with warehouse inventory management in the comments below, and to share this article with anyone who may benefit from it.