Intro

Optimize warehouse operations with effective inventory management, leveraging logistics, supply chain, and stock control strategies for maximum efficiency and reduced costs.

The importance of effective warehouse inventory management cannot be overstated. In today's fast-paced and competitive business environment, companies must be able to efficiently manage their inventory to stay ahead of the curve. This involves having the right products in the right quantities, at the right time, and in the right place. Effective warehouse inventory management is crucial for reducing costs, improving customer satisfaction, and increasing profitability. In this article, we will delve into the world of warehouse inventory management, exploring its benefits, best practices, and the latest trends and technologies.

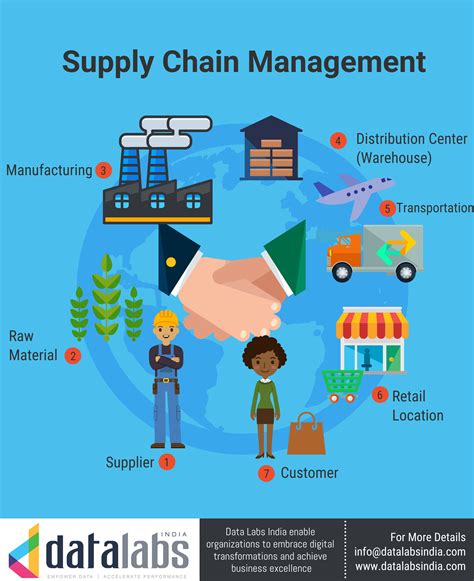

Warehouse inventory management is a complex process that involves multiple stakeholders, including suppliers, manufacturers, logistics providers, and customers. It requires a deep understanding of the supply chain, as well as the ability to analyze data and make informed decisions. With the rise of e-commerce and omnichannel retailing, the demands on warehouse inventory management have never been greater. Companies must be able to respond quickly to changing customer needs, while also managing their inventory in a way that is efficient, cost-effective, and sustainable.

As we explore the topic of warehouse inventory management, it becomes clear that there is no one-size-fits-all approach. Every company is unique, with its own set of challenges and opportunities. However, by understanding the principles and best practices of effective warehouse inventory management, companies can develop a tailored approach that meets their specific needs and goals. Whether you are a small business or a large enterprise, the benefits of effective warehouse inventory management are undeniable. By reducing waste, improving efficiency, and enhancing customer satisfaction, companies can gain a competitive edge and achieve long-term success.

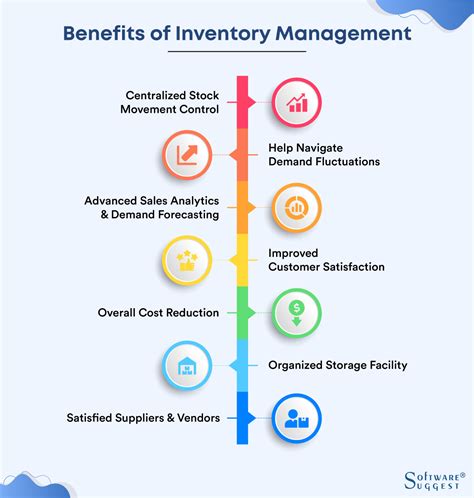

Benefits of Effective Warehouse Inventory Management

- Reduced inventory costs: By minimizing inventory levels and optimizing storage space, companies can reduce their inventory costs and improve their bottom line.

- Improved efficiency: Effective warehouse inventory management enables companies to streamline their operations, reducing the time and effort required to manage their inventory.

- Enhanced customer satisfaction: By ensuring that products are available when customers need them, companies can improve customer satisfaction and loyalty.

- Increased productivity: With a well-designed inventory management system, companies can automate many tasks, freeing up staff to focus on higher-value activities.

- Better decision-making: By providing real-time data and insights, effective warehouse inventory management enables companies to make informed decisions about their inventory and supply chain.

Key Principles of Effective Warehouse Inventory Management

To achieve the benefits of effective warehouse inventory management, companies must follow certain key principles. These include:- Accurate inventory tracking: Companies must be able to track their inventory levels in real-time, using a combination of manual and automated systems.

- Effective inventory classification: Companies must classify their inventory into different categories, based on factors such as demand, lead time, and storage requirements.

- Optimal inventory levels: Companies must determine the optimal inventory levels for each product, based on factors such as demand, lead time, and storage costs.

- Efficient storage and handling: Companies must design their warehouse layout and storage systems to minimize handling and storage costs.

- Regular inventory audits: Companies must conduct regular inventory audits to ensure that their inventory records are accurate and up-to-date.

Best Practices for Warehouse Inventory Management

- Implementing a warehouse management system (WMS): A WMS is a software system that enables companies to manage their warehouse operations, including inventory tracking, storage, and shipping.

- Using barcode scanning and RFID technology: Barcode scanning and RFID technology enable companies to track their inventory levels in real-time, reducing errors and improving efficiency.

- Implementing a first-in, first-out (FIFO) inventory system: A FIFO system ensures that older inventory is sold or used before newer inventory, reducing waste and improving inventory turnover.

- Conducting regular inventory cycle counts: Regular inventory cycle counts enable companies to verify the accuracy of their inventory records and identify any discrepancies.

- Providing training and support for warehouse staff: Warehouse staff must be trained and supported to ensure that they understand the importance of effective inventory management and are equipped to perform their jobs efficiently.

Common Challenges in Warehouse Inventory Management

Despite the benefits of effective warehouse inventory management, many companies face challenges in implementing and maintaining a well-designed inventory management system. Some of the common challenges include:- Inaccurate inventory records: Inaccurate inventory records can lead to stockouts, overstocking, and other inventory-related problems.

- Insufficient storage space: Insufficient storage space can lead to inventory congestion, reducing efficiency and increasing costs.

- Inadequate training and support: Inadequate training and support for warehouse staff can lead to errors and inefficiencies in inventory management.

- Lack of visibility and transparency: Lack of visibility and transparency in inventory management can make it difficult for companies to track their inventory levels and make informed decisions.

- Inability to scale: Inability to scale inventory management systems can limit a company's ability to grow and expand its operations.

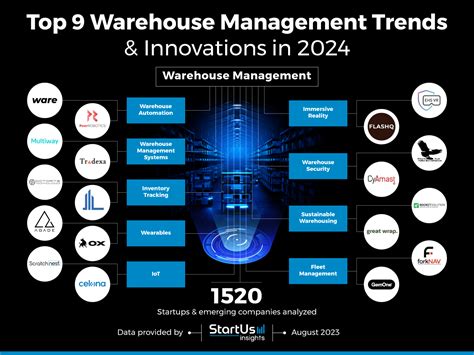

Trends and Technologies in Warehouse Inventory Management

- Artificial intelligence (AI) and machine learning (ML): AI and ML are being used to improve inventory forecasting, demand planning, and supply chain optimization.

- Internet of Things (IoT): IoT is being used to track inventory levels, monitor storage conditions, and optimize warehouse operations.

- Cloud-based warehouse management systems: Cloud-based WMS are becoming increasingly popular, offering greater flexibility, scalability, and cost savings.

- Robotics and automation: Robotics and automation are being used to improve efficiency, reduce labor costs, and enhance inventory accuracy.

- Big data and analytics: Big data and analytics are being used to provide real-time insights into inventory levels, demand patterns, and supply chain performance.

Future of Warehouse Inventory Management

The future of warehouse inventory management is exciting and uncertain. As technology continues to evolve, we can expect to see even more innovative solutions and trends emerge. Some of the potential future developments include:- Increased use of AI and ML: AI and ML are likely to play an even greater role in inventory management, enabling companies to make more accurate predictions and optimize their supply chains.

- Greater adoption of IoT: IoT is likely to become even more widespread, enabling companies to track their inventory levels and monitor their storage conditions in real-time.

- More emphasis on sustainability: As companies become more focused on sustainability, we can expect to see a greater emphasis on reducing waste, minimizing carbon footprint, and optimizing inventory management for environmental benefit.

- Increased use of robotics and automation: Robotics and automation are likely to become even more prevalent, enabling companies to improve efficiency, reduce labor costs, and enhance inventory accuracy.

Implementing Effective Warehouse Inventory Management

- Conducting an inventory audit: Companies must conduct a thorough inventory audit to identify any discrepancies or inaccuracies in their inventory records.

- Implementing a WMS: Companies must implement a WMS to enable real-time tracking and management of their inventory levels.

- Providing training and support: Companies must provide training and support for warehouse staff to ensure that they understand the importance of effective inventory management and are equipped to perform their jobs efficiently.

- Monitoring and evaluating performance: Companies must regularly monitor and evaluate their inventory management performance, identifying areas for improvement and making adjustments as needed.

Conclusion and Final Thoughts

In conclusion, effective warehouse inventory management is critical for companies seeking to reduce costs, improve efficiency, and enhance customer satisfaction. By understanding the benefits, best practices, and latest trends and technologies, companies can develop a tailored approach that meets their specific needs and goals. Whether you are a small business or a large enterprise, the importance of effective warehouse inventory management cannot be overstated. By implementing a well-designed inventory management system, companies can gain a competitive edge and achieve long-term success.Warehouse Inventory Management Image Gallery

What is warehouse inventory management?

+Warehouse inventory management refers to the process of managing and controlling the inventory levels, storage, and movement of goods within a warehouse or distribution center.

Why is effective warehouse inventory management important?

+Effective warehouse inventory management is important because it enables companies to reduce costs, improve efficiency, and enhance customer satisfaction. It also helps companies to make informed decisions about their inventory and supply chain.

What are some best practices for warehouse inventory management?

+Some best practices for warehouse inventory management include implementing a warehouse management system, using barcode scanning and RFID technology, implementing a first-in, first-out inventory system, and conducting regular inventory cycle counts.

What are some common challenges in warehouse inventory management?

+Some common challenges in warehouse inventory management include inaccurate inventory records, insufficient storage space, inadequate training and support, lack of visibility and transparency, and inability to scale.

How can companies implement effective warehouse inventory management?

+Companies can implement effective warehouse inventory management by conducting an inventory audit, implementing a warehouse management system, providing training and support, and monitoring and evaluating performance.

We hope this article has provided you with a comprehensive understanding of effective warehouse inventory management. If you have any further questions or would like to share your experiences, please don't hesitate to comment below. Additionally, if you found this article informative, please feel free to share it with your colleagues and friends. By working together, we can improve our understanding of warehouse inventory management and develop more effective strategies for managing our inventory.