Intro

Discover what cogs are, their types, and functions in machinery, gears, and mechanical systems, including gear trains, transmissions, and toothed wheels.

The term "cogs" refers to a crucial component in machinery and mechanical systems. Cogs, also known as gears, are toothed wheels that transmit rotational motion from one shaft to another. They play a vital role in changing the speed, direction, and torque of the motion. In essence, cogs are the building blocks of mechanical systems, enabling the efficient transmission of power and motion.

Cogs have been used for centuries in various forms, from simple water clocks to complex industrial machinery. The concept of cogs has evolved over time, with advancements in materials and manufacturing techniques leading to the development of more sophisticated and precise gear systems. Today, cogs are an integral part of many modern technologies, including automobiles, robotics, and aerospace engineering.

The importance of cogs cannot be overstated. Without cogs, many mechanical systems would be unable to function efficiently, and the world as we know it would be vastly different. Cogs have enabled the creation of complex machines that have revolutionized industries and transformed the way we live and work. From the gears in a bicycle to the sophisticated transmission systems in modern cars, cogs are an essential component of modern machinery.

Introduction to Cogs

Cogs work by meshing together, allowing the rotational motion of one shaft to be transferred to another. The teeth of the cogs interlock, enabling the transmission of power and motion. The shape and size of the cogs determine the ratio of the input and output speeds, as well as the direction of the motion. Cogs can be designed to change the speed, direction, and torque of the motion, making them a versatile and essential component in mechanical systems.

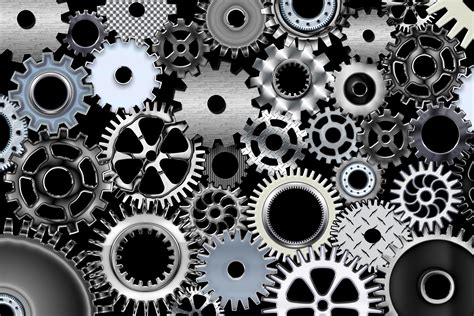

Types of Cogs

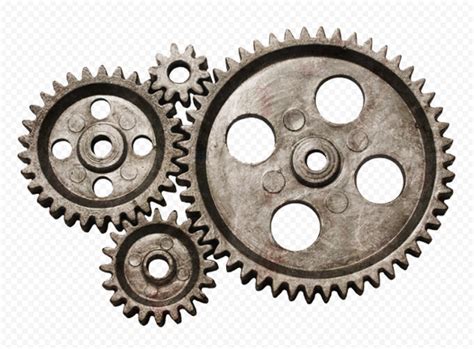

There are several types of cogs, each with its own unique characteristics and applications. Some of the most common types of cogs include: * Spur gears: These are the most common type of cog and are used in a wide range of applications, from simple machinery to complex industrial systems. * Helical gears: These cogs have angled teeth and are used in applications where high speeds and loads are involved. * Bevel gears: These cogs have teeth that are cut at an angle and are used in applications where the direction of the motion needs to be changed. * Worm gears: These cogs have a spiral thread and are used in applications where high ratios and low speeds are required.How Cogs Work

Cogs work by using the principle of mechanical advantage. When two cogs are meshed together, the rotational motion of one cog is transferred to the other. The ratio of the input and output speeds is determined by the ratio of the number of teeth on each cog. For example, if one cog has 20 teeth and the other has 40 teeth, the output speed will be half the input speed.

The efficiency of cogs depends on several factors, including the design of the cogs, the materials used, and the lubrication of the system. Well-designed cogs with proper lubrication can achieve high efficiencies, while poorly designed cogs can lead to energy losses and reduced performance.

Cog Materials

Cogs can be made from a variety of materials, each with its own unique properties and advantages. Some of the most common materials used to make cogs include: * Steel: This is the most common material used to make cogs and is known for its high strength and durability. * Aluminum: This material is lightweight and corrosion-resistant, making it ideal for applications where weight is a concern. * Brass: This material is resistant to corrosion and has a low friction coefficient, making it ideal for applications where wear and tear are a concern. * Plastic: This material is lightweight and inexpensive, making it ideal for applications where cost is a concern.Applications of Cogs

Cogs have a wide range of applications in various industries, including:

- Automotive: Cogs are used in the transmission systems of cars and trucks to change the speed and direction of the motion.

- Aerospace: Cogs are used in the gearboxes of aircraft and spacecraft to change the speed and direction of the motion.

- Robotics: Cogs are used in the gearboxes of robots to change the speed and direction of the motion.

- Industrial machinery: Cogs are used in a wide range of industrial machinery, including pumps, compressors, and conveyor belts.

Cog Maintenance

Cogs require regular maintenance to ensure they continue to function efficiently. Some of the most common maintenance tasks include: * Lubrication: Cogs need to be lubricated regularly to reduce wear and tear. * Inspection: Cogs need to be inspected regularly for signs of wear and tear. * Replacement: Cogs need to be replaced regularly to ensure they continue to function efficiently.Cog Design

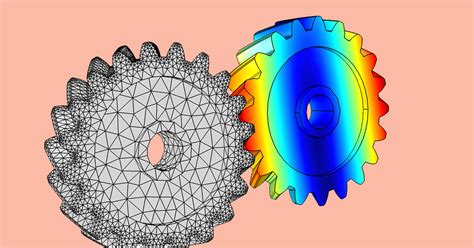

Cog design is a critical aspect of mechanical engineering. Cogs need to be designed to meet the specific requirements of the application, including the speed, direction, and torque of the motion. The design of the cogs also needs to take into account the materials used, the lubrication of the system, and the maintenance requirements.

Some of the key considerations in cog design include:

- Tooth profile: The shape and size of the teeth determine the efficiency and accuracy of the cog.

- Pitch circle diameter: The diameter of the cog determines the speed and direction of the motion.

- Face width: The width of the cog determines the torque and load-carrying capacity of the cog.

Cog Manufacturing

Cogs can be manufactured using a variety of techniques, including: * Casting: This involves pouring molten metal into a mold to create the cog. * Forging: This involves shaping the metal using a die to create the cog. * Machining: This involves using a machine tool to cut and shape the metal to create the cog.Cog History

The history of cogs dates back to ancient times, with evidence of cog-like devices being used in ancient Greece and Rome. The modern cog, however, is a relatively recent invention, with the first gearboxes being developed in the 18th century.

Over the years, the design and manufacture of cogs have evolved significantly, with advancements in materials and manufacturing techniques leading to the development of more sophisticated and precise gear systems. Today, cogs are an integral part of many modern technologies, including automobiles, robotics, and aerospace engineering.

Cog Future

The future of cogs is exciting, with advancements in materials and manufacturing techniques leading to the development of more sophisticated and precise gear systems. Some of the key trends in cog development include: * Increased use of advanced materials, such as composites and nanomaterials. * Increased use of computer-aided design and manufacturing techniques. * Increased focus on sustainability and energy efficiency.Cog Image Gallery

What are cogs used for?

+Cogs are used to transmit rotational motion from one shaft to another, changing the speed, direction, and torque of the motion.

What are the different types of cogs?

+There are several types of cogs, including spur gears, helical gears, bevel gears, and worm gears.

How are cogs designed?

+Cogs are designed using computer-aided design and manufacturing techniques, taking into account the specific requirements of the application, including the speed, direction, and torque of the motion.

What are the benefits of using cogs?

+The benefits of using cogs include increased efficiency, accuracy, and reliability, as well as the ability to change the speed, direction, and torque of the motion.

What are the common applications of cogs?

+Cogs are used in a wide range of applications, including automotive, aerospace, robotics, and industrial machinery.

In conclusion, cogs are a crucial component in mechanical systems, enabling the efficient transmission of power and motion. With their rich history, diverse applications, and ongoing development, cogs continue to play a vital role in shaping the world around us. Whether you're an engineer, a manufacturer, or simply someone interested in the intricacies of mechanical systems, understanding cogs is essential for appreciating the complexity and beauty of modern technology. We invite you to share your thoughts and questions about cogs in the comments section below, and to explore further the many fascinating aspects of this essential component.